With a preliminary report before CastTec 2014 we posed the question “Does tradition have a stake in the future?” Now, after the 2nd International Conference CastTec 2014 took place at Ravensberger Park, Bielefeld, Germany from November 20 through November 21, 2014 we answer with a clear “Yes, tradition does have a stake in the future”.

130 attendees from 10 nations (Germany, Beglium, Italy, Finland, Japan, Denmark, Spain, Netherlands, Switzerland and Poland) experienced interesting lectures of high quality and used the opportunity to visit the accompanying exhbition where well-known companies of the branch presented their delivery and performance scope and invited for dialogue.

After Dr.-Ing. Erwin Flender, MAGMA GmbH in his role as President of the Federation of German foundry industry, BDG, spoke the keynote „Progress is our tradition“, 18 highly qualified lectures grouped in three Topics under the headlines “Material”, “Process” and “Component” revealed new and interesting facts about the future of cast iron material, about details in metallurgy and application and showed how experience in intensive research and application are put into practice.

In Topic 1 “Material”, Ms Prof. Dr.-Ing. Babette Tonn from the Technical University Clausthal, Institute of metallurgy, as Chairperson led through five lectures with the following titles:

Cast iron alloys for exhaust applications by Dr. sc. techn. Werner Menk, Georg Fischer Automotive AG, Schaffhausen, Switzerland

SiWind® - a higher strength ductile cast iron for the wind energy by Dipl.-Ing. Peter Mikoleizik, Siempelkamp Giesserei GmbH, Krefeld, Germany

New Simulation Concept based on Metallurgical Quality Prediction in Real Time by Ramón Suárez, IK4-AZTERLAN, Durango, Spain

Characterisation of cast iron's toughness properties by damage mechanics by Dr.-Ing. Sebastian Münstermann, Forschungszentrum Jülich GmbH, Jülich, Germany

A fracture mechanically based strength analysis of planet carriers for wind turbines made of high strength cast iron by Luisa-Marie Heine, RWTH Aachen University, Institute for Materials Applications in Mechanical Engineering (IWM), Aachen, Germany

Mr Dipl.-Ing. Hartwig Haurand from HegerGuss GmbH was Chairman of Topic 2 „Process“ where the following seven lectures were presented:

Influence factors and evaluation of potentials sustainable development partnerships in the foundry industry by M. Sc. Robert Christian Fandl, Hamburg University of Applied Sciences, Hamburg, Germany

Energy management according DIN EN ISO 50001 - more than only technical energy efficiency by Dipl. Wirtsch. Ing. (FH) Benedikt Szukala, Siempelkamp Giesserei GmbH, Krefeld, Germany

Learning from experience - advanced process data analysis in foundry manufacturing by Prof. Dr.-Ing. Dierk Hartmann, University Kempten, Kempten, Germany

Casting Process Simulation as a Tool for Innovative Quality Management in Iron Foundries by Dipl.-Ing. Mathias Bodenburg, MAGMA Gießereitechnologie GmbH, Aachen, Germany

An innovative integrated CAE approach for the design and optimization of foundry moulding boxes by Giovanni Luca Di Muoio, Global Castings A/S, Lyngby, Denmark

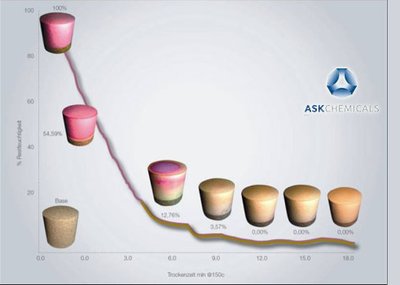

Contribution to the topic "Formation of the casting surface defect "white film" and relevant solution proposals by Dr.-Ing. Ekaterina Potaturina, ASK Chemicals GmbH, Wülfrath, Germany

Controlled Shot Peening - Applications and examples from large-scale components, engineering and series production by Dipl.-Ing. Oliver Schuchardt, Metal Improvement Company, LLC, Unna, Germany

Topic 3 “Component” led by Mr Dr.-Ing. Thorsten Schmidt from HEIDENREICH & HARBECK AG as Chairman was held on Friday, November 21, 2014 with the following six lectures:

Qualification of high-strength and ductile EN GJS 500-14 (Si-alloyed) from strand casting production for pressure components by Dr.-Ing. Peter Langenberg, Ingenieurbüro für Werkstofftechnik (IWT) Aachen, Aachen, Germany

500 MN Closed Die Forging Press by Dipl.-Ing. Klaus Schürmann, Siempelkamp Maschinen- und Anlagenbau GmbH & Co. KG, Krefeld, Germany

Consideration of cast iron materials in fatigue evaluation processes by Dipl.-Ing. André Heinrietz, Fraunhofer Institute for Structural Durability and System Reliability LBF, Darmstadt, Germany

Fatigue life assessment for large components illustrated at the example of the cement industry by Dipl.-Ing. Justin Bisping, ThyssenKrupp Industrial Solutions AG, Beckum, Germany

Verification of FE Simulation models for structural castings in Wind Turbines by Katja De Waegenaere, ZF Windpower Antwerp, Lommel, Belgium

Characterization of the porosity level in ductile iron and the effect on the fatigue properties by M. Sc. Sebastian Borgs, IfG Institut für Gießereitechnik GmbH, Düsseldorf, Germany

The social evening event “CastTec 2014 Banquet” on Thursday, November 20, 2014 afforded an additional occasion for interesting and fruitful conversations and discussions in a pleasant ambience.

After the end of lecture programme on Friday, November 21, 2014 the conference was rounded by an optional factory tour to CLAAS GUSS GmbH, Christophorushütte, at Gütersloh.

The next CastTec will take place in two years, estimated in November 2016.

More precise information about CastTec 2016, i.e. where and when, will be published by a Mark your Calendar postcard and online on www.casttec2016.com in early summer 2015 at the latest

<link http: www.casttec2014.com _blank external-link-new-window external link in new>www.casttec2014.com