<link https: issuu.com foundry-planet docs foundry-planet_e-magazine_turkey_20 _blank external-link-new-window external link in new> Metallurgy and castings have a deep rooted history in Turkey. The very first metal was smelted in Anatolia nearly 9000 years ago to make raw copper beads, later to alloy it with arsenic, tin or zinc to produce warfare, household or personel goods. This later progressed into the making of first wrought iron. This heritage was later on passed over to the following citizens of these lands, namely Romans, Byzantians, Selcukians and the Ottomans.

Metallurgy and castings have a deep rooted history in Turkey. The very first metal was smelted in Anatolia nearly 9000 years ago to make raw copper beads, later to alloy it with arsenic, tin or zinc to produce warfare, household or personel goods. This later progressed into the making of first wrought iron. This heritage was later on passed over to the following citizens of these lands, namely Romans, Byzantians, Selcukians and the Ottomans.

Starting from 1950’s, the private capital began to invest in foundries establishing modern facilities by which today the Turkish foundry industry can compete worldwide. Towards the end of the last century, Turkey has became a major supplier of foundry products for Europe. With a population of 78.000.000 and GNP at PPP terms (734 billion US $ in 2015). Turkey ranks at Nr 18 in the world scala and Nr 8 in Europe for GNP at PPP terms.

As for the Turkish foundry industry, even though there is a long and powerful history on the background, the growth was slow until the 1990’s, but from there on, the growth was with double digits. Major growth areas are in the ductile iron and aluminium castings, triggered with the automotive and machine manufacturing growth both domestic and in Europe

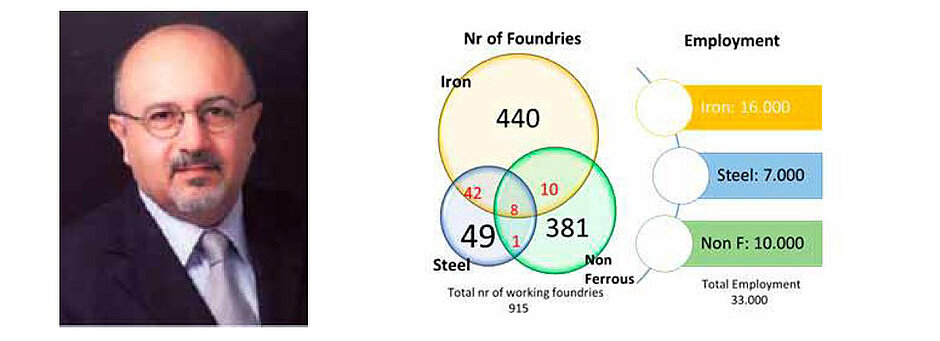

Turkish foundry sector acts an important role in world casting production, as well as it is in Europe. If we evaluate the numbers of casting production in 2014, after Germany and Italy, Turkey has taken 3rd place in Europe. According to AFS’s 49th Census of World Casting Production, which was published in December 2015 issue, Turkish foundry industry production in 2014 constitutes 1,7 % of the world production. Accordingly, Turkey’s global ranking is 10 with 1,750,000 tons. Total foundry production in 2015 has increased by 5,7 % compared to 2014. The figures that have been calculated from the data collected from the members of Tudoksad are given in Table 1.

Turkish Foundry Industry has invested over 3 billion US $ in the last 10 years for plants and equipment with up to date technology and achieved an installed capacity of 2 Million tons in Iron, 0,3 Million tons in Steel and 0,4 Million tons in Non ferrous castings in 2015. Most of these plants are distributed suitably throughout Turkey to serve the various domestic and international customers. Turkey being at a reasonably short distance to Central Europe, deliveries can be made in max 5 days by truck and 10 days by sea route.

In 2015, 62 % of Turkish casting production have been exported (Figure 1). A substantial part of the production has been exported to EU and to neighboring countries. In the total export figure, EU countries’ share is 77 %.

In addition to the machinery and equipment investment, the sector heavily invested also on human capital, training, research and development, as well as quality. Many foundries hold internationally valid ISO 9001, ISO 14001, ISO 16949 and OHSAS 18001 certificates.

One main advantage of Turkey, is the presence of surplus young and educated workforce, with English language knowledge and computer literacy and most important who are willing to work in foundries. As nearly all of the EU-Ecology and environmental laws are now in force in Turkey, all foundries are heavily investing in environmental protection machinery to fit in the new regulations.

Turkish casting production is expected to grow by 7-8% per year in the coming 5 year term. The main growth will be in engineered machinery components and high pressure die castings. New trends and progress in the Turkish foundry industry is on compacted graphite iron, ductile aluminium, high value added products, concept to product design, prototyping and testing, complete assemblies with machining, with various patent applications.

It is well realized by the Turkish foundrymen that, by combining low production costs with higher quality, improved productivity and newer technology, the sector would have considerable advantages in competing globally. The Turkish foundry industry has grown to a position that can not be disregarded.

Growth is not only on the annual production levels, but also on the technical side. This growth and the future is supported by the well trained and educated intellectual capital working in all levels of the foundry. Economical crisis periods periodically experienced in Turkey have thought the foundrymen how to reduce their costs, live with minimum financial depths, and still how to keep their customers. Products supplied at competitive prices, coupled with service, simultaneous engineering, value analysis, just in time delivery, flexibility, up to date technology and reliable quality will be the leading factors of the Turkish foundry industry in the liberal one single source market place of the 21st century.

<link http: www.foundryturkey.com>www.foundryturkey.com

Partner

Foundry Corporate News

Turkish Foundry Industry

Lesedauer: min

[18]