Abstract

People are the backbone of any organisation. Any one! – a big foundry or a small foundry; an automated foundry or a manual foundry. Any caste or creed of the foundry will be determined by its people. As the people are developed, the backbone gets stronger, there emanates an all-round benefit, in an ever maturing organisation, improving business process and people, with a higher and higher brand.

This paper discusses the pathway for an organisational success. The last portion of this part is fictional, giving a Benchmarkable description of the style a foundry must wear. Hope the foundry becomes capable!

But before that, the case for why individuals should be capable, and if they are not, then how can organisations synergise people’s competencies to close the gaps in individual’s capabilities is proposed. In the interim the training to individuals is continued strategically so as to make each one a role model of competencies. The assurance that ‘each one is capable’ should be forthcoming from this paper.

Key Words : 5’C’ model, Foundryman’s KRA’s (Key Result Areas) to develop competencies.

The Organisational People

Deming, the Guru, exhorted: Trust your men;

Philip Crosby voices: Let them be competent;

While Dr. Joseph Juran emphasized on: Control.

Mentor Ishikawa: Don’t tax Individuals more,

They’l work together, better in Quality Teams.

Peter Drucker: and If they have better genes!

…… they sure will muster their arts well!

Fiegenbaum: Foolproof systems are swell.

You Quiz: Is that the recipe for success?

Argues Priyavrat: “Is positivity your asset?”

Professes Covey: Hurry, sharpen your Axe.

calibrated vis-à-vis metrics at Garvin’s pace.

Well! Well-Designed systems succeed the fastest

quips Taguchi: limit process variation @ lowest!

Scours Senge: validate system-Safety past a test.

Yet, with full unanimity, we all decree ……….

Win-Win criteria for people’s evolution sustain,

When capable men fortify Organisations’ veins!

© copyright 2008 Priyavrat Thareja

Listed above, are proclamations Quality Guru’s nearly* made (* nearly: because these are derived by author as his own perception of their Quality contributions). These must do well to promulgate development of a Quality system, in any Organization. For, a paradigm to make their personnel competent: Where the Gurus are given the go, the good God’s wishes have surely bestowed!

The Journey to “I am Capable”

An organisation is constituted as a set of people who, together, synergise individual competencies to achieve newer dimensions. (Individually, each one may be of smaller magnitude, but together they become more meaningful). They (i.e. people) can extrapolate their ideas in different directions, using Brainstorming, and further endeavour to fill the gaps, and to shape ideas such that these become more meaningful and tangible (Thareja, 2006). Together they can identify newer pathways which may interconnect the re-researched areas. In the process they have not only achieved newer competencies but also learnt ‘how a newer collective competency was evolved’.

The process may be limited in words, but not in its applicability. While it fulfills the criteria of all-round gains: in terms of the competencies augmented by the participants; the organisation seeks newer directions to the business success, the individual brand image of both the people and the organisation, in turn, goes up. The competencies which were hitherto rated as being smaller, are better recognized and now acclaimed to be more potent and fruitful. Either way, the Organisation, the People, and the system of Quality Circles which enabled people to innovate in the interim have gained materially, and in terms of the confidence of delivering results.

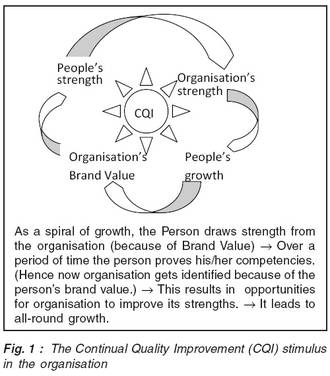

The organisational systems are, in fact, paradoxical. Initially the people are known because of the organisation they work in. They improve and demonstrate their presence by the visiting card they carry. Slowly it becomes the other way. It becomes the turn of organisations which itself gets identified because of these people. When such people grow up in stature, their organisation would have also grown, both because of the business they have brought to the organisation, and because of the stature the people in the organisation impart to the latter. There is thus an ever-growing stimulus of growth which is associated with capable people.

The Spiral of growth the organisation witnesses is exhibited in Fig. 1. It all rides on the shoulders of the people forming the organisation. Both are related systematically displaying a causal relationship. Regressively, capable people make an organisation capable. In return, capable people draw their strength from a capable organisation. It is thus the duty of the organisation to nurse their people to capability.

The Spiral of growth the organisation witnesses is exhibited in Fig. 1. It all rides on the shoulders of the people forming the organisation. Both are related systematically displaying a causal relationship. Regressively, capable people make an organisation capable. In return, capable people draw their strength from a capable organisation. It is thus the duty of the organisation to nurse their people to capability.

It may, however, be asked: “Can People outgrow the organsation?” Perhaps not, unless the organisation is such that it is devoid of co-operation and networking inside the organisation. Rather it is ensured that some strong work-groups have strategically been developed which are operational, with due success, and equipped with a wherewithal to improve all-around competence. Thus establishment of development teams of capable people is the key to successful organisations.

In essence, as the organisation was always constituted by the People (entrepreneurs), for the people (customers), and of the people (the capable people), the role of people is intensely vital. The systemic nature of this process suggests that if the ‘People’ focus must stay at the forefront of all sub-systems, then process dynamics be governed by innovative programmes to improve Customer’s satisfaction (Thareja, 2007a). <break>

Strategic Focus Areas

Strategic focus areas of such an organisation could be:

- To continually address Customer’s needs and ensure Customer’s satisfaction for the ultimate success of society. This needs the pre-requisite of a first-rate management of organisation core processes.

- Networking of competencies of people and development of synergy between the units of specialists (individual or at departmental level).

- Promotion and recognition of several Quality Circles/ Project Groups, who harbinger augmentation of such competencies for better product realization.

- Developing a learning organisation to support the welfare, know-how and abilities of the personnel as well as to ensure the success of the Networked Groups/ Quality Circles.

- Maximisation of organizational product in terms of fulfillment of Customer’s requirements, and concurrently match organizational performance and economical results to give added value for the resources, investments and People’s investiture.

- Since commensurate increase in People’s investiture with those of People’s product is a dynamic process, subject to this increase the possible realization from customers must be improved. The organization matches such competencies with the concurrent levels of fulfillment and adjusts costs and receipts.

- Consequently an evaluation system as a tool of continuous development need be instituted, to measure and monitor above said programmes.

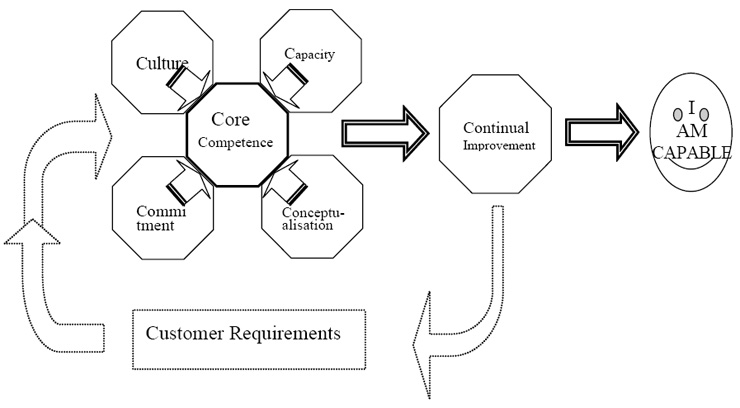

The Strategic focus areas of competent organizations as enlisted above need to be synergically aligned to detailed focus. There is a need for the networking of traits like culture, conceptualization, capacity and commitment so as to develop holistic teams. Availability of all such requisites in the team/ organisation helps it achieve the coveted core competency (of the team / organisation). This display of Core Competency (to which esteemed inputs are: Culture, Conceptualization, Capacity and Commitment) is essentially of the organisation and not of the individual, but when an organisation gets organized for Continuous Quality Improvement (CQI), the motivation exists for improvement of individual capabilities too. It is in line with what Albert Einstein professes: “Intellectual growth should commence at birth and cease only at death”… Yet, “The only thing that interferes with my learning is my education.”. Hence the need for a feed back based enabling system to identify core areas/ KRA’s (Key Result Areas) to develop competencies. The blend of these 5 constituents (5C’s) are proposed and schematically illustrated in Fig. 2.

Fig. 2 : Each one is Capable. Imperatives to be addressed are Personal Mastery, Culture, Commitment, Concentration / Focus and Capacity (5 C’s) ( for both Authorisation and Accomplishment). These attributes must be continually improved and concurrently matched for Competence to address Customer needs/ Requirements, until one is fully Trained and Capable

The process of Continuous Quality Improvement (CQI) essentially is identified with the Feedback subsystem. This step tends to evaluate discrepancies or gap areas in individuals, and the CQI endeavours in organisation can help address the shortcomings suitably. Required actions may include addressal of their quality management requirements using inputs through human resource management, or estimation and addressal of their educational needs.

Rejuvenatation of Competencies

The dictionary meaning of ‘Rejuvenation’ is ‘making people young again’. Not to demean the competencies which the persons had, the new set of competencies, which are short to “I am Capable” status must be added. Effort should be, rather, to implant the required competencies selectively, one by one. It may require some unlearning. That is why the control of environment is quite vital. Remember the Chinese Proverb “Tell me and I’ll forget; show me and I may remember; involve me and I’ll understand.” The challenge to be addressed is to evaluate existing competencies, and update with required set of competencies, duly analysed using specialized tests.

The discrepant people are stealthily influenced by one’s perceptions and actions without themselves really being aware of it. It is reiterated that mature organizations do not even make such endeavours/ gaps public. These are also not readily discussed or made explicit, unless some learning is planned by the leadership to broadbase the process intricacies for higher efficiency in further CQI.

The modus operandi of this schema is schematically illustrated through a card game shown in Exhibit 1. It will be clear from this illustration that why should there be a need to break one’s perceptions which, though wrong, are yet rigid enough to offer undue resistance. After all, it is not simple to break old habits. That is why a tactical approach is advisable, and it will ‘remain unchallenged until all alternative explanations have been explored’.

Exhibit-1

A Magic Trick to show the Power and Importance of Unwritten Rules (Ref. 3)

Benefits

• Incorporate the trick into a presentation.

• Use it to impress your colleagues, friends and family.

Time required

• Five minutes to do the trick and explain.

• Follow with discussion on unwritten rules.

Preparation

• Copy the Kings, Queens and Jacks from a pack of cards onto two separate presentation slides as above.

Instructions to Participants

• Look at the cards in Slide 1.

• From the six cards, pick one and make a note of the one you have picked.

• Now look at Slide 2.

• As if by magic, your card will be removed!!!

Explanation

All the cards in the second set are totally different from the first set. Therefore it does not matter which card you picked because they all change!

Learning Points

People perceive the second set of cards as identical to the first set and, therefore, behave as if the removal of their chosen card is due to some mysterious magical force! This perception is being driven by an unwritten rule that ‘the second set of cards is exactly the same as the first set’.

This unwritten rule:

• influences people’s perceptions and actions without them really being aware of it.

• is not readily discussed or made explicit.

• remains unchallenged until all other alternative explanations have been explored.

<break>

A Display of Capabilities by a Foundryman

It may be pertinent to highlight types of competencies which a Foundryman must display. These may be categorized as Technical, concerning Resources, Managerial issues, Production (process + product + design) Management, Quality issues and so on. A process is mapped and streamlined so that the output can be governed as per requirement. Like an Output “I am Capable” as illustrated in Fig. 2. The control process is in the hands of CQI, whether it qualifies the process (or individual) as capable or not.

Consider the Process Profile given below!

Process Profile

When it is necessary to make a casting Perfectly Right,

There is a scientific procedure: for set of 8 steps to alight.

Go, set in the controls for Process Parameters as Tight,

Say, for good Optimization, there is an all around fight,

And, the scope of applying Taguchi Techniques is bright,

Only, a partial factorial test, a fewer experiments to bite.

You’ve attested all goals correctly, duly focused in Sight?

Ensured a culture: skill @ Technology to synergise Might?

That’s an ultimate recipe, to abate Foundry defects quite.

© copyright 2008 Priyavrat Thareja

Evidently production of a Sound casting, free from defects, is the foremost competency of a Foundryman. It is rather a life-line of a competent manufacturing system. Say, Casting ? Competent Manufacture ? Component. It is foremost, because a defect entails a series of losses to the foundry: scrap, delays, energy dissipated, maintenance, disposal, loss of face and its unethical extensions, worker’s morale, loss in Brand value and so on. The author has witnessed a justified ‘tendency to forgo a stipulated percentage of impending profit’, on the part of a foundry entrepreneur, so as to ensure that the probability of occurrence of a defect may be reduced. An extra pad in the casting, extra ounce of Nickel or any other high priced alloying addition, an extra step in an already configured process, if that can reduce the onslaught of rejection, he counted them in, say, like an insurance cess. Assurance to make the casting ‘First Time Right’ is not more enlightening than to meticulously maintain production schedules. The benefit of faster turnover (though at lower profit) is evident, of course for the same indulgence in assigned work. The inputs to a casting is the same – whether the casting were saleable or not.

Cast’in of a ‘product’ in a sound mould is a synonym of Culturing a Concept in a mould of Core competence. It contemplates a Commitment, Cultivated Continually, to improve the technology to a robust state. In order to ensure production of a Sound casting, free from defects, the Foundryman must assure himself that all the goals have correctly been focused in Sight before a casting initiative is undertaken. After all, the purpose is not only to address DFC (Design for Castability) issues, but also the DFNX issues (Design for ‘Not’ X (Unknown factor(s) or parameters) Thareja (2007b). Taguchi methods address choosing outputs @ S/N ratios (signal to noise ratios) for which a lower output can be envisaged. A case where S/N ratio is highest (@ lower the better defect rate) is chosen as preferred output.

The advantage of Taguchi technique is in employing a shortcut method (called partial factorial) which guises itself as a highly effective route to success, where at any time not more than 25 % of the resources need be earmarked. Taguchi techniques also enable the researcher to carry out a Systematic analysis supporting System Design, Parametric Design and Tolerance Design of given product and/or process (Kakria and Thareja, 2007). The 8 Steps to alight a Taguchi technique are mapped in Exhibit 2.

Exhibit 2

8 Stpes for Creating a Robust Design 1. Identify the Main function. |

The various points, viz. Technical competencies, process, product, experimentation, design, management, Quality issues etc. have been described as needed in the lines above. Identification and addressal of these competencies is subject to the judicious Quality Management Process planning. Developing all the five competencies (5 C’s) integrated as in Fig. 2 for developing a holistic-core-competency is the purpose of any educational cum HR cum Quality Management planning initiative. The vision that ‘every single person is capable, encouraged and enabled to work with others to improve their part of the service’ (Penny 2002) is long term commitment and needs a big change in our culture. It comes with Education, which can impart the analytical power to judge what is conducive to the good, the benefit, the welfare of all. As “education creates both new wants and provides the ability to satisfy them”, it is essential for Change. Hence, all progress implacably requires change while Change may not necessarily assure progress.

Quality education, with Quality as a guidemap, however, provides a base for addressing the anomalies in education and training, and align them vis-à-vis improvement culture available. However, as can be expected, most of the organizations are averse to the ‘promise’, even though they may be necessary for coveted learning-for-life skills.

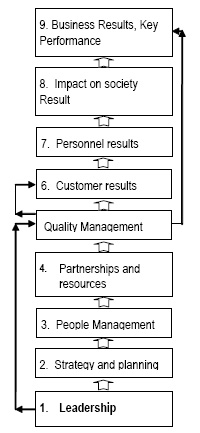

When Chaudron (1993) says: “If Skill is Not the Problem, Training is Not the Solution”, he identifies ‘skill’ as a product of training. Similarly, Experience too is a concurrent product of training. The holistic agenda to take requisite action thus depends interactively upon all the skill, training and education. Then only Education becomes meaningful and convincing. Chides Chaudron, “When trainees leave the classroom without a plan for using their newly learned skills and no way to implement them…(it) is like teaching someone how to use a hammer and never giving him an opportunity to use it”. The Foundrymen must provide requisite Leadership (Fig 3).

Fig. 3: The Process map to begin a Quality Management based process for Reuvenating People to “ I am Capable” |

Quality Management Process Planning to Engineer : “Each One is Capable”

For a Quality organisation, development of Human resources is on the agenda for many angles. In this race the need of people for sustainable business performance is abysmally small. There are many more responsibilities. New projects, newer business loads/opportunities, changes at the competitors, employee turnover and personal pressures, Changes in Technology and training, developmental activities, re-adjustments in processes due to changes in markets all are affected @ people. The Organisation is thus challenged to maintain a reserve potential of people at the back. Those who do not, will starve for people, like the Foundry industry does.

The foregoing mention of continual catering to the need for People does in no way assert that the people are like inventory, where the Just in Time (JIT) process is applicable! People are certainly not like an inventory, for people need to be acclimatised to the organisation, work systems, hierarchical formations, development programmes and synergising of teams et al. People are more than the individuals. People have to be identified with the organisation, and that takes time. The bonds of Loyalty should be nursed; and if that were not stable, the organisation will remain permeable by the competitors.

It is, therefore, safe to assume that for the development of people, who are capable, the Quality management system (QMS) is intended to be very useful. The steps begin form the People at the higher echelon of the organisation. i.e. the Leadership itself. It is, in fact, these People, who understand the people, and render the developmental push, by even being one of them. The lower in hierarchy the act from, more harmonious are the Quality outcomes (Thareja,2007 c). In fact, input to QMS is directly from the leadership, which assures the intent, signifies a vision and hence General line of direction, the mission that is the target for the shorter goal, and the goal that is the work assigned for now. All such inputs are to the QMS, and the responsibility of management’s spokesman – the MR (management representative) to disseminate amongst the organisation and monitor progress as feedback to top management. The schema is Flow charted in Fig. 3.

The nine Functions detailed in Fig. 3 are those vital KRA’s (Key Result Areas) which can be monitored and even researched for maximization of necessary stimulus in the Foundry. Assignment of Individual Roles and responsibilities in key operations follows after a ‘mutual alignment’ for developing the quality management has been engineered. Discussed below are descriptions as compiled by the author and put across with a taste as if these were duly implemented in… a kind of Fictional Foundry. Hope this is your own story too! <break>

Elements of a Dream Foundry

1. Leadership

The essence of leadership is in making values visible through open communication and decision-making. The values, mission, vision and guidelines for annual business/ product development may be written in a check-list formed as a result of two-way dialogue between employees and superiors.

The leadership facilitates that people’s newer personal targets are set and the expected and mutually agreed results are monitored. During the discussion the personal development plan is also specified. The information needed are development needs of the organisation, customer satisfaction surveys, labour market surveys and individual training needs. The aim of the personal development plan is to combine the needs of an individual and the organisation. Employees also have an opportunity to tell their opinions about leadership and management and bring out new development ideas.

The management monitors the achievement of expected annual outputs with the help of personnel inquiries, customer feed back, different statistical and financial information about products, personnel, processes and projects and summaries of self and external assessments.

Values |

2. Strategy and Planning

The strategies and operational principles as well as the Quality Management System of foundries should be based on TQM (Total Quality Management) philosophy. According to this philosophy many foundries develop continuously their processes from the customers point of view. The aim is to achieve customer satisfaction and loyalty through better learning results and sound economy.

The strategies for a Foundry may include: mission, vision, values, strategic focus areas etc that are common to all units and independent profit units. The Foundry also needs to focus on the special strategies, which may concern all inside the Foundry, viz. Personnel strategy, Founding training strategy, International Strategy, Environmental strategy, Communication strategy etc. The strategies are evaluated annually in connection with the operational and financial planning. The profit units set the new objectives for the strategic focus areas by using the information from self assessment and external assessment as well as the customer, performance and financial results obtained in the last year. The personal objectives for carrying out the strategies are set in twoway dialogue discussions between employees and their superiors.

Strategic plans are split into action plans and objectives at unit level.

Most important action plans of units include:

• Operational and financial plan with annual objectives and measurement indicators. Also objectives for common strategic focus areas are included.

• Personnel plan

• Action plans of different teams

• Action plans of projects

Quality Management System of a foundry may consist at two levels:

(i) Strategic Level

- Common Alignments at Foundry level:

– Strategy in Foundry level (mission, vision, values, strategic focus areas), Quality Policy, as well as

– Personnel strategy, International strategy, Environmental strategy, Adult training strategy, Communication strategy etc. - Common Alignments and their own strategies at Unit level

–Setting of annual objectives and monitoring of expected outputs

–Profit centres have their own strategies created in co-operation with personnel and interest groups (mission, vision, values and the strategic focus areas for their own development).

(ii) Operational Level

- Units concentrate on carrying out their own mission and vision. For example, guiding products to learn with correct learning methods

- Units create successful working conditions for personnel and products by removing the obstacles. Personnel and products know what is expected and what kind of work is appreciated.

- Self / external assessment : Assessments give the information how far the units are from the common strategic focus areas and the vision.

3. People Management

Every unit of the Foundry has its own Quality Coordinator. The tasks of these co-ordinators are:

- To spread quality philosophy and to guide quality work

- To participate and consult the steering group of the unit

- To organise self assessment process

- To take part in strategic planning

- To develop information gathering and surveys

- To organise different inquiries and surveys in cooperation with other personnel

- To inform about quality development work and quality training

- To co-operate with training co-ordinator team of the Foundry

- To develop benchmarking

These Quality Co-ordinators belong also to the companywide Quality Co-ordinator Team. On the Foundry level the tasks of this team are to develop the assessment system and to organise the self and the external assessment processes.

The team develops the common guidelines, for example customer presentations, performance and financial results and the other information needed for negotiations with Managing Director. All decisions are made in the Profit Centres Principal Team. The representative of Quality Co-ordinator Team gives the presentation to Profit Centre Principal Team. The representatives of Quality Co-ordinators Team have participated in a project of the Board of Education with the aim to develop recommendations for quality management of vocational education at the national level.

Internal benchmarking has been possible for units during the whole history of the Foundry. The Quality Co-ordinator Team analyses all assessment results. It has been also possible to read and analyse application documents of other units. The Quality Co-ordinator Team will start benchmarking with other educational organisations and enterprises as well. The Foundry will arrange due visits to symposia or techmarts.

Quality improvement is one of the main objectives in human resource development of the Foundry.

Other objectives are:

- To promote life-long learning

- To promote development of a learning organisation

- To promote change processes

- To promote internal integration of the Foundry

- To develop capabilities and raise the level of knowhow of personnel

- To promote learning by doing

- To promote competitiveness of the Foundry

Quality Training Programme : Every employee in the Foundry has a personal development programme. “Training for each one is capable”, as objectives, deploys:

- Trainer: Master of Quality, Master of Science in Process Engineering, Vocational Teacher, Black Belt in Six Sigma.

- Trainees come from different profit centres of the Foundry and from co-operation organisations.

- Training gives tools to continuous improvement and assessment of an organisation by spreading understanding about quality philosophy, tools and quality management system of the Foundry

- Contents: quality philosophy, problem solving, process management and development, customer orientated operations, self assessment with Quality Award.

4. Partnerships and Resources

Every unit of Foundry carries out annual self and external assessments. The Quality Co-ordinators co-ordinate the quality application document. The steering groups of the units carry out the self-assessment and employees participate also. The Foundry has its own Team of Assessors. The team consist of all those Quality Coordinators who have the competence for the same.

The Quality Co-ordinators can use 3 to 4 hours per week for quality work. Inter Quality Co-ordinator Team meet approximately twice a month. Every unit has computer programmes for evaluation and for inquiries and their analysis.

5. Quality Management Process

The aim of the quality work is to support development processes of the units in the way the strategies show. Operational and financial plans of the units are evaluated annually by self and external assessments. The purpose of quality evaluation is to give information about how far each unit is from the common strategic focus areas. In addition, the units find their own improvement areas and set their own objectives. The results of evaluations are used in budget to set objectives, in two-way dialogues between foundrymen and seniors for guidance of operations.

The quality is built up inside the units of the Foundry. It means that management, human resources, core and co-operation processes as well as strategies and action plans, communication and customer satisfaction are developed from the customer, performance and financial point of view.

The aim of customer-oriented development is to get better learning results, to create new learning supporting cooperation models with labour market, to create new capabilities and development of working life. In addition the aim is to educate and train capable, skilled persons for society and labour market and to create the best possible learning conditions for every individual learner.

6. Customer Results

Every unit takes feedback from customers. Inquiries are made, for example, concerning total satisfaction and to what extent products have been satisfactory.

7. Personnel Results

The competence analysis and the atmosphere analysis have been made for the personnel of the Foundry. Every unit of the Foundry gets feedback from its own personnel, say: training proficiency, satisfaction etc.

8. Impact on Society

Foundry has a key role in national manufacturing strategy. The long-term aim of the strategy is to develop World Class foundrymen, who can build World Class foundries.

Development of Competitiveness of SME´s sector visà- vis Foundry SME’s is dependent upon successful Estimation of Planning Needs and Quantity-Quality Founding Project.. Trainers of the quality project are members of the Quality Co-ordinator Team of the Foundry.

9. Business Results, Key Performance

Well! a future Annual Report will read like this:

“There is a pressure for operational economy. The most important reason for that is that there is an increase in energy costs and environmental degradation cess. But the Foundry has improved our work systems, because “our people are Capable”, and we withstood the recessionary pressures well....” <break>

Concluding Remarks

1. A 5C model for Personal Mastery i.e Culture, Commitment, Concentration / Focus and Capacity for Core Competency (5 C’s) is proposed.

2. The need for individual’s capability is reiterated, and the need of devising a mechanism to synergizing gaps in individual’s capabilities by synergsing competencies is proposed.

3. A schema of a Quality managed Foundry is illustrated, which can be used as a Roadmap for new alignment to Quality.

4. Strategic focus areas of such an organisation (Foundry) are proposed. This includes the need for continuous Quality Improvement and continual Training.

5. A game plan for tactically handling people under training/ probation is illustrated.

References

1. David Chaudron, (1993), If Skill is Not the Problem, Training is Not the Solution” The Quality Source Magazine (p. 34336) ASQC, Spring

2. kakria Ravneet, Singh Chandandeep, Thareja Priyavrat, (2007), “Quality Improvement Of Aluminium Alloy (Lm-6) Casting Using Taguchi Method”, Indian foundry Journal, Nov

3. Penny (2002), Building and nur turing an improvement culture Personal and organisational development Improvement Leaders’ Guide, Department of Health, © Crown Copyright 2005 London SE1 6XH,

4. Thareja P, (2006), ‘A Total Quality Organisation Through People; Part 6, Innovation Competencies’ FOUNDRY, Vol. xviii, No. 6, Nov/Dec 2006 5. Thareja Priyavrat, (2007a), ‘Teams, Traits And Tasks [QT3] For Total Quality’, Communicated Quality World (May 2007)

6. Thareja Priyavrat (2007 b), Use Of ‘Not’ In Dfx For Tomorrow’s Most Competitive Manufacturing, Proceedings of National Conference on Trends in Mechanical Engineering, TME 2007, Aeronautical Society of India and CIET, Distt Patiala ,Jan 19,, 2007

7. Thareja P 2007c, “A Total Quality Organization Thro’ People, (Part 10): Leading from the bottom” , FOUNDRY, Vol. XIX, No. 4, July/Aug 2007

The Author and the Article

Prof. P. Thareja’s article series on "Total Quality Organization Thru’ People" delves on Foundrymen’s holistic competency development paradigm. Previous 15 parts focussed on:

Prof. P. Thareja’s article series on "Total Quality Organization Thru’ People" delves on Foundrymen’s holistic competency development paradigm. Previous 15 parts focussed on:

1. Quality Depends on Your People

2. Roles and Responsibilities of People

3. Effecting Breakthrough Improvements

4. Building-up a World Class Foundry

5. People as Change Agents

6. Innovation Competencies

7. Strategic Alignment

8. Excellent People and the People

9. Team-up to Total Transformation

10. Leading Foundries from the Bottom

11. Insulate the People from Quantity

12. Caught in Fuzzyness of Output and Perfection

13. Competent Intrapreneurship

14. Sustainable Improvement, to World-Class Operations

15. Winning thru idiosyncrasies

This 16th part focuses on “Each One is Capable”. It discusses the pathway for an organisational success, through the journey of identifying & imparting training to each employee, to make him more and more capable in his functions.