also available <link _top>![]()

Industrial robots "off-the-peg" often don't often offer the die-caster any specific support in programming and operation, no special aids during casting procedure and no interfaces for the necessary safety system. Software modules proven in practical operation simplify operation and programming of robots, offer highest safety, support the casting process and ensure an improved quality of the parts and an increase of the productivity.

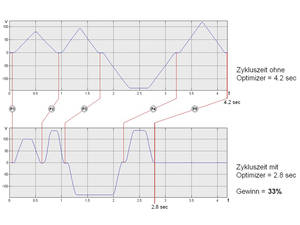

Fast removal of parts at the casting machine and short cycle times in the subsequent automation steps, for instance checking and trimming, are achieved with the optimizer function of the Reis RobotStarV software (fig. 1). This software tool optimizes the programmed robot movement in such a way that the machine reserves regarding amplifier current and motor moment will be utilized to an optimum, without overloading the drive components. Optimization is effected online during the robot movement.

<link file:7268> |

<link file:7269> |

Complete automatic casting cell with removal | The Optimizer Function improves the |

<link file:7270> |  <link file:7271> |

With the user-related user interface CastAssist | Maintenance of the trim tool by the operator |

Then the acceleration parameters are adapted in such a way that the available drive capacity will be utilized to an optimum. The axes speeds always remain under control of the programmer as they normally represent a quality determining parameter in a production process. The optimizer allows an optimum movement time in any operating mode of the robot. Thus, it is possible to reduce the conventional cycle times by up to 30 % (fig. 2).The robot model considers alternating payloads and also allows the integration of additional loads onto different robot axes. A typical application is the removal of castings. The optimizer can utilize its complete potential with the continuously changing loads between running with and without load. Another optimized application is handling of castings in an X-ray cabin.The degree of optimization can be set optionally at arbitrary positions in the program sequence. This allows a smooth movement during transportation of sensitive workpieces or liquid materials such as molten metals and a quick movement when running without load.The Optimizer only engages the traversing profile of a programmed movement. The path itself remains as the user programmed it. There is no danger of collision due to the modified robot movements.The advantages of this software function are obvious:

Depending on the movement program a reduction of the cycle time up to 30 % is possible;

- Easiest application without previous knowledge;

- Time consuming optimization of movement programs and machine parameters is avoided;

- In the program the degree of optimization may be selected freely between 0 and 100 %, thus a time optimum operation or reduced operation due to application may be set.

Programming in the language of the caster

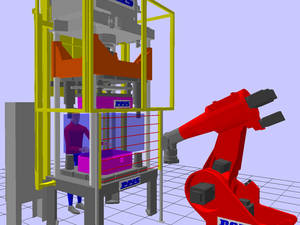

With the module CastAssist the Robots of the Reis GmbH & Co. KG Maschinenfabrik, Obernburg, can be operated and programmed even faster and easier in the foundry. This is due to the new user-related operating surface of the module. The software function offers the caster an application related programming and operating surface where the most important commands can be selected via clear graphical symbols (fig. 3).

The module is designed for all important functions in the foundry sector. The individual software modules for die casting, gravity die casting, handling and interlinkage offer the customer programming software customized for his application which will allow simple operation and programming in a workshop-oriented language. For the die casting process, for instance, or for robot programming six groups of commands graphically represented are available:

- Control of casting and cooling,

- Airblast of mold and application of spray medium,

- Interlinkage with the casting machine,

- Interlinkage with the trim press,

- Return to robot home position.

After selection of the corresponding group of commands the user has only to select the requested command shown as simple text and acknowledge a corresponding parameter, e.g.. ”gripper open”, ”gripper close”. Then the command will either be effected directly or be shown as text on the display of the portable teach pendant and taken over into the program. Thus time consuming comment lines are omitted. With this simplification even employees who only seldom operate the robot are able to make modifications quickly and in a reliable way and to intervene into the program.

Pre-prepared libraries for putting into practice different functions may be read in via data transfer later. The user has the possibility to configure their own operator surface with macros or to adapt existing user functions to his special requirements. These advantages are available to the caster not only directly on site at the portable teach pendant, but also in the offline programming system RobOffice.

Delicate removal of the casting

The software function CastEject at the removal robot, specially designed for removal of castings from the mold or gravity die, allows the robot axes to be kept in a balanced condition without position and speed regulation. Thus, the casting can be demolded synchronously with the hydraulically operated ejector movement.

After the casting machine has opened, the robot gets the signal to move in and pick-up the casting in the open die. After the message "gripper closed" the robot gives signal "ejector forward" to the casting machine. With the ejector movement the robot is pushed away with the part until the casting is free for removal from the casting machine.

This function has several advantages. On the one hand, the casting will be removed gently from the die and won't be bent. Thus it can be inserted exactly into the fixture of following processing stations and trim tools. Even delicate cast compounds thus can be removed perfectly to be further machined. Jamming of the casting at the ejector is avoided. Thus, there won't be created any scratches on the part during removal of casting. Also the robot is spared from damage. The head axes don't get any uncontrolled hit from the ejector with each removal process.

Flexible safety control required

Due to the increasing concentration of processing steps in all ranges of the foundry the production systems are becoming more and more complex. At the same time flexible safety concepts are required allowing the caster to quickly control and modify the production algorithm so that the desired production goals are always achieved. To meet the above mentioned requirements, a flexible safety control that can be configured will be required: This can be achieved by the use of a SafetyController integrated in the control hardware, for instance. This new technology has the following advantages. All monitoring functions are implemented in software and replace expensive safety components like safety switches, safety relays, cam paths and cam switches.

In the safety control there is integrated a PLC permitting both an interlinkage of defined Cartesian safety areas with each other and safety areas with external safety signals, e. g. of safety doors.

During production the worker can freely move in defined and programmed spaces within the robot cell. A personnel-safe monitoring of the robot axes allows this. Simultaneous works on the trim tool are possible, e.g. cleaning of the fixtures with open safety grid of the press during automatic operation of the robot (fig. 4).

Another automation example is an automated casting cell with several casting machines in gravity die casting. The casting and removal robot continue working while the operating and service personnel performs maintenance works on the casting machine in the line. This is an important condition for high production availability.

Integrated, freely programmable PLC functions

In very compact, small and medium casting cells there often is required an additional PLC to control and manage materials-handling technology and checking stations. Here the control RobotStarV offers a cost advantage. The robot control provides for a second processing level with a freely programmable PLC function. The PLC program is generated in a language based on the STEP-5 language of Siemens. Direct input of the program to the robot control is possible with the portable teach pendant. With this integrated PLC peripheral processes can be controlled and monitored even asynchronously to the robot program, without significant additional hardware and software expenditure with an external PLC control.

Maintenance of molds and gravity dies with Augmented Reality

Programming of industrial robots today is still mainly done with the portable teach pendant directly at the robot by teach-in procedure. In order to make programming more intuitive, the robot manufacturer Reis has integrated a graphical user interface into the robot control ROBOTstarV, which is based on Augmented Reality technology.

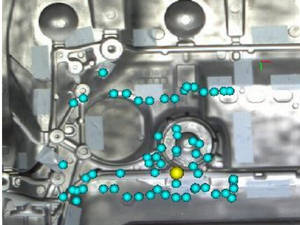

Augmented Reality means "extended reality" and represents a new way of man-machine interaction. Information from the robot control, e.g. positions, paths, program data, will be faded into a real camera picture depending on the context, i.e. suitable for the object looked at, and at the same time represented on the PC monitor.

The functionality of Augmented Reality is integrated into the new operating surface based on graphics, ProVis-AR (Programming and Visualization in Augmented Reality) and may be used directly with a PC connected to the control. Since the new user interface is based on internet technologies, an installation of special software to the PC is not required. After calling the homepage of the robot the user interface will be loaded from the control to the PC and will be available there.

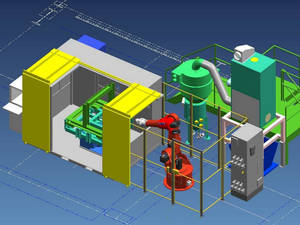

This software function is used for cleaning and maintenance of gravity dies at a big German automotive manufacturer. In a blasting system (fig. 5) the gravity dies are blasted and cleaned with a robot. The operator sees the intensity of soiling on the gravity die by means of a video image. With a PC-mouse the worker selects the areas to be cleaned. Then the robot control selects the corresponding blasting program and fades in the path positions defined there (fig. 6) on the screen.

After release for start by the worker sandblasting is effected for the selected area. Blast process being finished there automatically will be generated and displayed a new image of the blasted gravity die. At the same time the most important operating elements are faded in which serve for the following decisions:

- Gravity die in order,

- Reblasting required with identical parameters,

- Reblasting with modification of the blast intensity of position shift.

A great advantage of this application is the gain in time and the gentle treatment of the gravity die. Unsoiled areas won't be blasted, needless material wear is avoided.

Further advantages of a user interface in Augmented Reality technology are the simple and intuitive handling and identification of complex three-dimensional formations like a robot or a complicated workpiece forms. The intuitive handling with program data, positions and parameters gives certainty to the user and thus allows a simple and safe way to work with the robot. All information necessary for the user's work will be presented to him clearly without having to pore over program lists and manuals. The user may choose just one or both the textual representation or the visual program representation of his user program at the same time. Both representations complement one another.

High quality in gravity die casting

For the optimum automatic casting process in gravity die casting the programmed ladling and pouring is of decisive importance for the quality of the casting. The robot control from Reis offers this special, field-proven casting software. The particularity of this is that the caster can manipulate both ladling and pouring without programming knowledge via simple commands on the portable teach pendant. Thus, a continuous casting process is also reached if exterior influences require a modification of casting parameters. The modifications will be immediately taken over online in the next cycle. Besides this, various gravity dies with different volumes can be loaded with this. This is made possible by free programming of the robot control and management of several different casting programs at the same time in the active work memory of the control. Thus, also the ladling quantity may be different, depending on the gravity die just introducing the casting and ladling procedure.

<link file:7272> |  <link file:7273> |

Gravity die blasting system with robot | ProVis-AR in practical use: Information from |

The filling procedure into the gravity die that follows is important for the quality of the product. Filling of the liquid aluminum without air inclusions and oxides is mandatory. For this purpose, a nearly constant volume stream during filling procedure must be achieved. Furthermore it is possible to modify the volume stream during the filling procedure, adapted to the product.

Filling into the gravity die requires enormous sensitivity with regard to the pouring speed and casting path. This is possible due to division of the filling path described by the robot into various different path segments that can be influenced individually. So each path segment can be defined differently in its pouring angle and can be modified in its speed, independent from the total path. The robot program automatically adopts the chosen parameters for optimization of the pouring procedure. They guarantee a recurring constant pouring movement and thus, a constant quality of the product. In addition, the process can be monitored, acquired, evaluated, displayed, and documented directly via the robot control.

Synchronous pouring

The software function CastTracking is required for casting systems with tilting casting machines and for rotary casting machines. The pouring process is constantly optimized for each process and thus allows a high casting quality.

At the tilting casting machines with hydraulic tilting drive a position measuring system of a robot axis is mounted on the tilting axis delivering the required signals and positions to the robot control. The hardware can be purchased from the Obernburg robot manufacturer. This module is also mounted on the rotary axis of the rotary casting machine so that the robot can be synchronized with the carousel.

An electric tilting drive on the casting machines using a spindle is even more elegant. The spindle drive with integrated position measuring system is a real robot axis being fully integrated in the robot control.

This concept offers all advantages for a slow or quick synchronous pouring with tilting of the casting machine. Ladle and casting machine are always moving at same speed.

Rotary casting machines with tilting casting machines where the robot pours in the liquid aluminum precisely and true to path while the carousel is turning continuously and the casting machine is tilting are particularly sophisticated. This application practically can only be executed only conditionally without the software module.

Contact to <link _top>Reis Robotics USA in our Suppliers Profile

<//font>