ASK Chemicals to stage its products for large iron and steel casting applications

From June 13 to 16, ASK Chemicals will be staging its solutions for large casting applications at Metal + Metallurgy China 2017, placing special emphasis on its ALPHASETTM technology, its locally manufactured EXACTCASTTM KMV mini-risers, and its innovative UDICELLTM tubular filter systems.

Highly recommended for steel applications

With its portfolio of ALPHASETTM binders, the supplier of foundry consumables offers a wide range of products that meet every requirement. Their excellent properties, such as high heat resistance, sufficient thermoplasticity, and minimized casting defect rates, make ALPHASETTM particularly suited to large-scale casting in the iron and steel industry. ALPHASETTM is a two-component binder system composed of a water-based resol and a liquid ester as the reaction partner. The unique water-based and sulfur-free system eases the burden on the environment significantly. A key advantage of the system is the extremely low development of odor and VOCs during core production and casting. In addition, the system is nitrogen-free.

For the reclamation of ALPHASETTM sands, ASK Chemicals provides an extensive portfolio of additives for thermal reclamation.

Risers for maximum yield with minimum volume

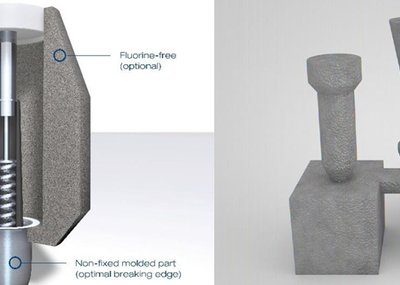

Conventional sleeves used in steel applications contain, in addition to the fibers, rice husks that may lead to casting defects. Moreover, these slurry sleeves do not utilize their full volume for counteracting shrinkage defects, so that the effective yield is only 30%. The remaining 70% of the volume are used to maintain the heat in the 30% of the molten metal needed for feeding. This is exactly where the cold-box-bonded EXACTCASTTM KMV mini-risers come in, offering a fiber-free solution for steel casting. The volume of the riser can be reduced without sacrifice to the feeding performance. The exothermic compound replaces the non-feeding material and maintains the metal in its molten state. The KMV mini-risers therefore present an efficient and reliable alternative to conventional slurry sleeves. Thanks to this saving, the foundry can produce more cast parts with a single furnace batch or even serve entirely new markets without investing in expanding the furnace capacity. The lower riser residue on the cast piece means that the reworking costs per cast piece are also lowered (Fig. 1).

Maximum robustness for double-digit tonnages

UDICELLTM tubular foam ceramic filters are perfectly suited to the secure filtering of large quantities of liquid metal, and they feature a unique value-added design. The advantages of this design include more than three times the filter area compared to a conventional plate-shaped filter of the same size, a self-supporting geometry, a minimized risk of filter breakage, a compact structure, and a quick and easy installation (Fig. 2).

ASK Chemicals Casting Academy

On June 14, 2017, ASK Chemicals will be hosting an open ASK Chemicals Casting Academy featuring lectures on its key solutions and leading technologies:

Solutions for steel and large casting applications; featuring ALPHASETTM, EXACTCASTTM KMV mini-risers and UDICELLTM tubular filter technology / June 14, 10:00 am – 12:00 noon, Room N1M40

Environmentally-friendly foundry solutions; featuring different lectures on INOTECTM as well as on water-based coatings technology / June 14, 2:00 pm – 4:30 pm, Room N1M40

Foundrymen who are interested in joining the ASK Chemicals Casting Academy are cordially invited to participate. ASK Chemicals is looking forward to fruitful discussions with customers, prospective customers, and partners at its Booth A27 in Hall N1.

Partner

Foundry Corporate News

Topic Chemicals

Fairs and Congresses

Big solutions at Metal + Metallurgy China 2017

Reading time: min

[9]