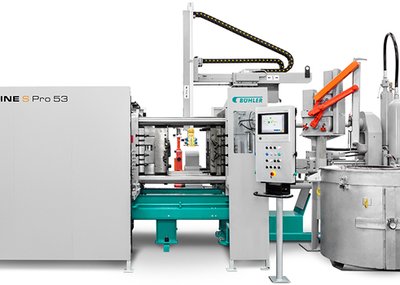

Particularly suitable for die casting applications with high volume flows, the new Oil Cleaning System from Bühler can reduce hydraulic system breakdowns by up to 60%.

Clean oil is a vital factor for a stable production. One factor that impacts on the availability of die casting production systems, is the uptime of the hydraulic and lubrication system. This is mainly influenced by contamination of the oil – e.g. through particles, oil ageing or water in the oil.

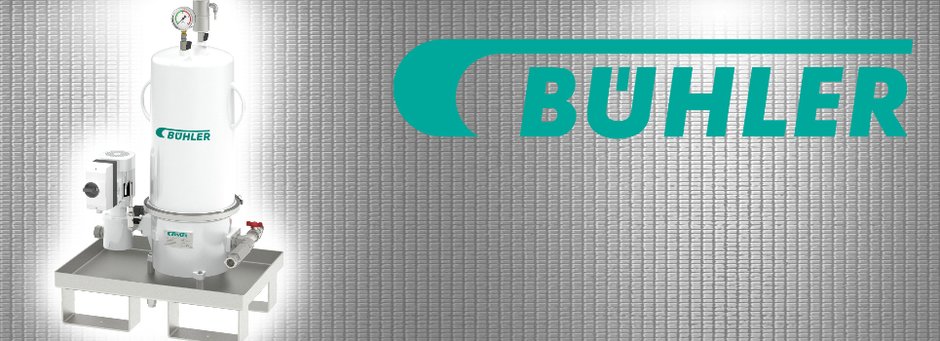

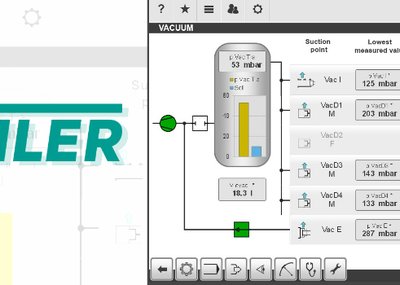

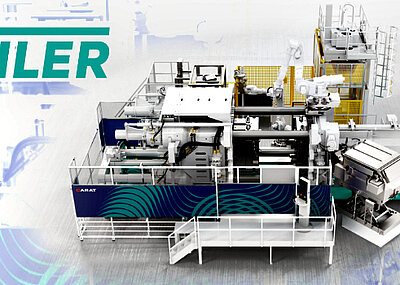

To improve the quality and lifetime of the oil in the die casting system the usage of a filter system is an important step. Therefore Bühler introduces the Oil Cleaner. The system has a depth filter insert, meaning that contaminants are retained in the depth of the filter insert. This ensures a very high dirt holding capacity as well as a longer filter lifetime. The system maintains water glycol 24/7 and thereby reduces wear on pumps, valve and hydraulic components.

The result of the filter implementation is a higher productivity of the die casting cell, less scrap and a higher uptime for the whole cell. Additionally, longer change intervals of the fluid can lead to lower service and maintenance costs.

Important to say – the Oil Cleaner also helps to protect the environment. Less friction in the system due to cleaner oil results in lower energy consumption. And, the Oil Cleaner filter consists 100 percent of renewable raw material. Therefore the disposal of the filter material does not additionally impact on the environment.