also avaible in <link _top>

|

Dipl.-Kfm. Hans-Georg Ehrmann (left)Dipl.-Kfm. Sigrid Röth-Ehrmann from Georg Röth Eisengießerei GmbH & Co.with Michael Colditz (right) from DISA

|

On 28. and 29. October 2009 there was held the DISA-Symposium in Bad Wimpfen, a medievial small town near Heilbronn (Germany).So DISA offered business partners and parties the opportunity to inform themselves about the experience in the installation of a DISA 130-A at the Georg Roeth foundry in Mosbach. During an interesting programm of lectures DISA gave detailed informations on the latest developments of the DISA and Wheelabrator products.

At the beginning of this event the DISA 130-A, which has been recently installed at the foundry in Mosbach, could be viewed during operation. Because of the great numbers of participants the tour took place in two groups. The manager of the Georg Röth foundry, Mrs. Sigrid Roeth-Ehrmann and Mr. Hans-Georg Ehrmann, and the casting director, Mr. Dietrich Beck, were available for all the questions.

Click here to enlarge <link file:7377 _blank>

The participants of the DISA-Symposium at Georg Röth Eisengießerei GmbH & Co.

| |

|

Click to enlarge <link file:7378 _blank>

Soeren Skov-Hansen (application engineer), Niels Winther Rasmussen (product manager), Matthias Kuhne (manager core shooting equipment), Michael Colditz (area sales manager) and Michael Tissarek (area sales manager global service) (from left) |

In the ensuing lecture series, which took place at the hotel "Rosengarten" in Bad Wimpfen, Mr. Beck introduced the experiences about the whole installation and commissioning of the DISAMATIC. A lot of questions showed the real interest of the participants. The other lectures with the topics " The product of DISAMATIV-form lines and new developments" and "The strömungsgerechte gating system - developments in power engineering" could give a deep insight into the possibilities of a DISA molding line.

|

All the topics were busy discussed during the ensuing common dinner, of course.

<link _top>Click here for picture gallery

Click to enlarge <link file:7379 _blank>

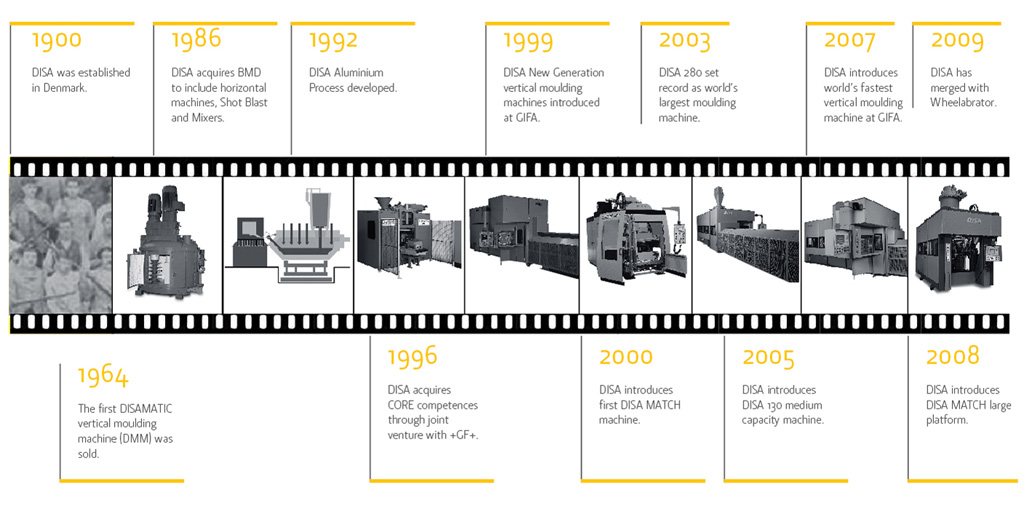

Norican Group |

The lectures on the following day gave detailled informations about TOPS, the service program of DISA, the Wheelabrator blasting equipment, sand preparation and DISA-core machines.

This first of - we hope - more symposia was a well-organzied event with a lot of valuable informations and good oppurtunities to share experiences.

<link _top>Click here for more information and contact details of DISA Industrieanlagen GmbH in our suppliers profile

<link _top>Click here for more information and contact details of Georg Röth Eisengießerei GmbH in our suppliers profile