Material recycling in the Industry

Many materials have to be comminuted before further processing - this includes different chips and stamped parts made of plastic and metal, but also valuable precious metals such as gold and silver as well as laboratory samples. In this process, a part of the raw material often remains in the crushing machine. In order to recover the precious material, the plant had to be opened and cleaned demanding much time and effort up to now. Erdwich Zerkleinerungssysteme GmbH, therefore, has equipped its proven Single-shaft shredders M400 and M600 with a hydraulic Easy Cleaning construction, which allows to safely open the machines with little time effort and to perform a cleaning.

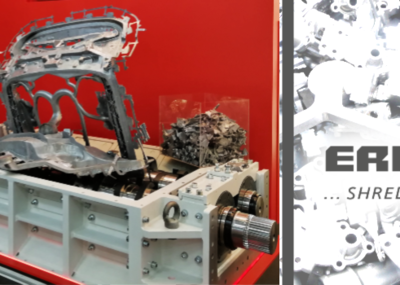

The Single-shaft shredders M400 and M600 have proven themselves in many different industries since their development. Among other things, they comminute plastic and metal chips, castings and stamping parts, hospital and electronic waste, but also zinc slag, aluminium, steel and plastic, and in cement plants, they prepare substitute fuels for analysis in the laboratory. For particularly sensitive areas, the plants were now once again revised and optimized: "Both models are now available on request with an easy-cleaning hydraulic system. Thereby, the plant can be opened at the push of a button to clean the collecting container and the cutting system of the machine."

Advantages are achieved especially in industries working with sensitive or very expensive materials, such as in research, environmental and pharmaceutical laboratories. There, often the samples must be processed and crushed before they can be analysed regarding their chemical composition. In these processes, however, the materials to be examined may, by any means, not be contaminated by residues of previously comminuted samples. Thus, a regular cleaning of the shredding plant is essential. With the new technology, the interior of the plant can be checked and cleaned of residues particularly quickly and with little effort.

Reuse valuable materials loss-free

The same applies to particularly valuable materials such as gold and silver, which are used, among other things, in the production of luxury goods. Here again, an energy-efficient implementation is being considered increasingly. For this reason, the raw materials are first comminuted before melting and further processing, since this accelerates the subsequent process steps. "However, it can happen that the material is not 100 percent removed and residues remain in the machine. In the case of gold, silver or other rare raw materials, losses of a few grams can become an expensive matter," Mr. Graf explains. "The newly developed hydraulic solution improves workflows and efficiency considerably and reduces material losses."

The plants still have individual, interchangeable knife discs at the cutting rotor, allowing for maintenance to be carried out within a short time. Furthermore, the knives are cured and can be re-grinded several times. Because the knife discs can be individually put on the cutting rotor and the perforated wire geometries can be adapted to the operational requirements, throughput and particle size are easy to control. In addition, at development a great emphasis was put on the fact that the plants can also process moist material. This is made possible by the outside shaft bearing as well as the integrated ballast wall, whereby neither grinding material nor liquid materials can get into the bearings. "Should unexpected problems arise, for example, if the machine is overloaded or solid parts get into the system, both the M400 and the M600 have a PLC Control with automatic reversing and shut-off, so the machine is protected against damage," Mr. Graf states. The M400 and the M600 are each available in two different versions, mainly differing from each other by the cutting unit size and the screen hole diameter.

Partner

Foundry Corporate News

Topic Plant Technology, Equipment

Topic Enviroment, Energy & Safety

Erwich: Cleaning without material loss

Reading time: min

[0]