also available in <link _top>![]()

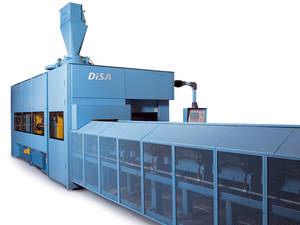

The Georg Röth Eisengießerei GmbH & Co. KG installs just this summer a new DISAMATIC- moulding system in Mosbach/Neckarelz in Germany. The new moulding system type DISA 130-A replaces an existing mould system with a smaller mould chamber. Commission and start of production will take place in August already. Because, of the Installation, the foundry will get a way bigger flexibility towards their customers since the mould surface is bigger but also the cooling length of the system is extended. The foundry builds the first moulding system of this type in Germany.

The DISA 130 was developed by DISA Industries A/S especially for smaller and medium size foundries with a higher frequency in pattern change. In addition to this it can produce up to 350 moulds per hour without using the core setter. While the production with using the core setter it can be produced up to 320 moulds per hour. With the new developed mould technology it is ensured a higher process reliability but also a much higher accuracy. This is possible because of a guaranteed maximum machine-related mismatch of 0,1 mm.

The system will be delivered in a total length of approximately 44 meters with integrated sand spillage conveyor underneath the pouring and cooling section. At the same time the shake-out and the sand return transport will be refurbished. This type of machine was sold up to now 23 times worldwide already which proves the sustainable development of the DISA Industries A/S for the benefit of their business partners in the foundry industry.

The system will be delivered in a total length of approximately 44 meters with integrated sand spillage conveyor underneath the pouring and cooling section. At the same time the shake-out and the sand return transport will be refurbished. This type of machine was sold up to now 23 times worldwide already which proves the sustainable development of the DISA Industries A/S for the benefit of their business partners in the foundry industry.

Since the foundation in 1890 the Georg Röth Eisengießerei GmbH & CO. KG got a good reputation as customers’ foundry; especially for the machine building industry. The main focuses of their production are thin walled and/or core intensive castings in smaller and middle size series with partly complicated design with high accuracy and productivity. The owner, Mrs. Sigrid Röth-Ehrmann, is convinced: with the started investment program they made an important step into the direction of securing the future of the location and the jobs of her 140 employees. After the optimization of the sand plant last winter is this investment another step to justify the sustainability of the family owned company in this economic hard time. The capacity of 16,000 t per year of good castings will be expand further over the 120 year anniversary of the foundry existence in the upcoming year.

For more information: <link http: www.roeth-guss.de>

Contact to <link _top>![]() DISA Industries A/S - in our Suppliers Profile

DISA Industries A/S - in our Suppliers Profile

Contact to <link _top>Georg Röth Eisengießerei GmbH in our Foundries Profile