Seen on the picture - starting from left: Dr. Norbert Röttgen (the German Federal Minister for the Environment, Nature Conservation and Nuclear Safety), Jürgen Pütz (Spokesman of the Board of Volksbank Bonn Rhein Sieg), Rolf Kurtsiefer (CEO of KMA Umwelttechnik GmbH), Prof. Dr. Klaus Bochard (Rector of the University of Bonn a.D.) |

Recently KMA Umwelttechnik achieved an Innovation Award for its energy efficient exhaust air filter systems, which was awarded by the German Federal Minister for Environment Dr. Norbert Röttgen at a ceremonial act. True to the motto "our environment is our future", KMA is producing for more than 40 years exhaust air filtration systems for the industry which are always based on environmental as well as energy efficiency. KMA started concentrating on sustainability long time before it became a trend. The utilisation of KMA exhaust air filters results in the reduction of environmental pollution caused for example by industrial smoke. At the same time they make an important contribution to climate protection due to minimal energy consumption. But how does the energy efficiency of the exhaust air filtrations work?

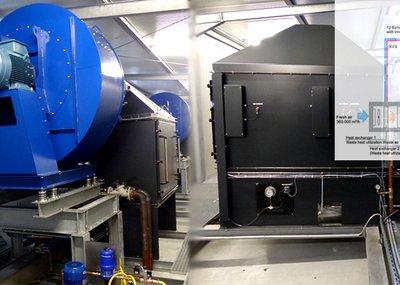

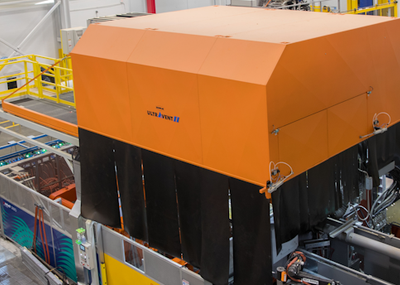

On cold days the operation of a conventional waste air ventilation system is an expensive job for foundries, because the warm exhaust air has to be replaced by the cold incoming air from outside, which has to be heated first. KMA offers a smart solution: in a first step the KMA ULTRAVENT waste air filters - which are basically made out of energy saving electrostatic precipitators - extract and clean the smoke from the die casting machines. In a second step the clean air returns back into the hall. An intelligent blower control can save additional energy costs compared with conventional exhaust ventilation systems. In many cases the total energy consumption of typical filter devices is reduced by up to 80 percent using ULTRAVENT air filtration systems.

In addition ULTRAVENT systems only use washable filter media such as demisters or electrostatic precipitators. The expensive replacement of used filter media is not necessary. The integrated automatic filter cleaning system cleans the filter elements regularly and ensures minimal maintenance. KMA filters are made of high-quality material, making them extremely robust and long-lasting.

In order to maintain a position as a technological leader, KMA invests a high portion of its turnover into the advancement of its filtration systems. Therefore KMA collaborates closely with its customers as well as with research institutions and Universities. Recently KMA Umwelttechnik worked in partnership with the University of Cottbus and designed and patented a new a new method for separating high-resistant dust.

| KMA Umwelttechnik GmbH is a leading supplier. For further information and contact details click here: KMA Umwelttechnik GmbH |