In developed areas in China the number of available labor is falling. This particularly concerns hard manually work like fettling shops in foundries. Therefore the costs for such work increases every year.

Considering this situation Suzhou Suzhu Foundry Machinery Manufacture Co., Ltd. introduced compact CNC based Cut & Grinder machines for the Chinese market, MGM Muschna Giesserei-Maschinen (www.mgm-foundry.de) for the European and Overseas markets.

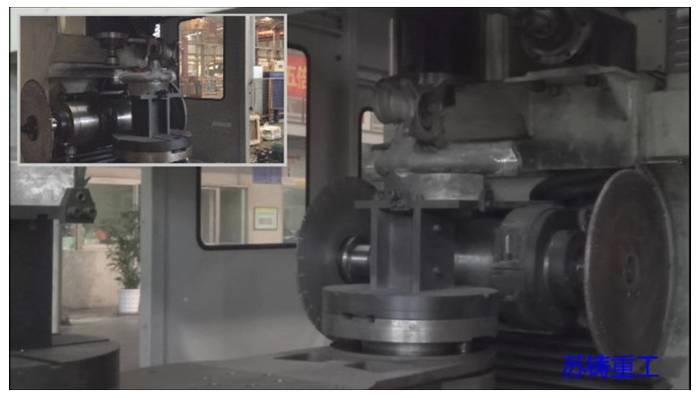

The SUZHU Cut & Grinder is applicable not only to CNC grinding of castings, but also includes cut off risers on the same machine before grinding. The machine is highly productive due to ergonomical design including a unique turntable for exchange and fix castings.

The SUZHU GRINDER’s are fully automatic CNC contour grinding machines and are suitable for complete grinding and de-burring of different kinds of castings with complex surface. The SUZHU GRINDER’s have a high load capacity (casting weight up to 180 kg), a robust design and ensure high productivity due to rapid change over of work pieces.

The two-station turntable gives free access by hoist to the casting setting and pick-up place, while the second casting is machined at the same time. One worker may control two machines. The 4-axis-motion system SIEMENS SINUMERIK 828D and the high precision six servo-drives and linear guidance’s assure high repeatability of grinding process and low grinding tolerances. Exactness of positioning of grinding tools +/- 0.1 mm. Repeatable casting grinding result is less than +/- 0.5mm, very close tolerances.

Two different kinds of diamond grinding tools with excellent lifetime allow grinding of different castings of arbitrary shape, with rapid and thorough grinding of angles. It is not necessary to re-adjust the tool location, no wear compensation.

Supply in CE-conform execution with appropriate safety devices and enclosure. Connection to a dedusting system recommended. No pit, small foundation footprint.

Low investment and operating costs characterize the SUZHU GRINDER.

The optional supplied CNC riser-cutting and contour-grinding machine is equipped with an additional Numeric axis-motion, servo-drive, linear guidance and one additional diamond riser-cutting wheel.

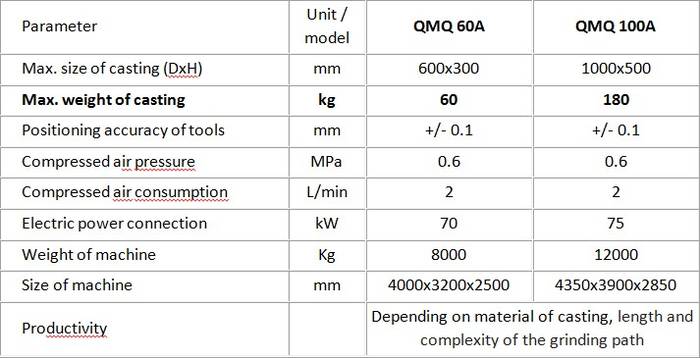

Technical characteristic of SUZHU GRINDER

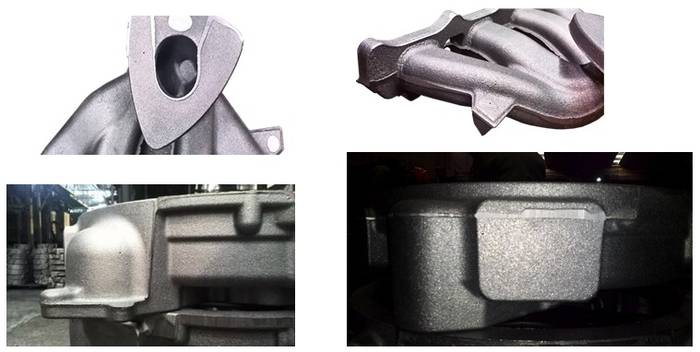

Examples

grinding of exhaust manifolds - 27 pcs. per hour

Flywheel housing

188 sec cycle time including work piece changeover by turntable turning for move in / move out of castings No. 1 and No. 2 and move to / from grinding position approx. 18 sec

For further information about SUZHU products contact MGM Muschna Giesserei-Maschinen, Germany, at www.mgm-foundry.de . SUZHU and MGM are looking forward to meeting you May 17th – 20th at Metal China 2016 exhibition, Hall W3, booth 13.

×