|

|

|

|

|

|

|

|

|

|

Article also available in <link _top>

„We can abandon 45 years of experience in investment casting, at least with regard to the drying of the ceramic shell”. With this statement the plant manager of a large European investment casting foundry got to the heart of his experience with the Cyclone high-speed drying procedure of MK-Technology in Grafschaft/Germany.

With this new technology the drying times of ceramic shells for investment casting parts can be reduced considerably even with water-based slurries.In the past, the shell building with water-based slurries took 2 or 3 times longer than with alcohol-based slurries. This increased the delivery time considerably, which is no longer acceptable, especially for the main customers of investment casting products, the automotive, aircraft and motor industry. Due to the fact that 95% of the mould production is drying time, this process had to be drastically reduced in order to make the shell building technology also applicable for the field of Rapid Prototyping in the future. This is exactly the point where the development of MK Technology is brought into action. The following report will explain how this new technology works, show the advantages and describe where it can be applied.

Water or alcohol

While in the beginning mainly alcohol-based silica sol, so-called alcosol, was used as ceramic slurry for investment casting, these slurries have now been replaced mainly by water-based systems.

The lower costs for the water-based material was one of the reasons for this change, but the main reason was the tightened MAC value (Maximum Allowable Concentration), which finally squeezed the alcohol-based slurries with their sweetish smell that reminds of glue out of the European investment casting foundries. An advantage for human beings, the environment and the margin does not necessarily have to be an advantage for the technology and the process.

All water-based slurry systems have one significant disadvantage: Contrary to the alcohol-based slurries the drying time is much longer. The standard shell building can take one week or even longer. With the conventional alcohol-based binder it was 2 to 3 times faster. Therefore, it is no surprise that a lot of investment casting companies did not really like to give up the alcohol-based material, as this prolonged the processing time dramatically. This might be the reason why the conversion to water-based slurries has not been done up to 100 %. The investment casting process is long and complex. Fast design checks or pilot series are not possible with this technology and delivery times of several weeks or even months are more the rule than an exception. Business for the main customers of the investment casting industry such as Automotive, Aircraft and Motor Industry is booming resulting in a great demand for investment casting parts, extending the delivery time for urgently needed parts. The customer has to accept it for better or worth.

Expedited mould drying

For MK Technology, a special engineering company specialized in Rapid Prototyping, it is easy to develop quick production techniques. Basically the task was simple: The water inside the slurry had to be extracted as gentle and fast as possible. The wax part under the slurry had to stay undamaged and the bond of the slurry, which is very important for the strength of the shell, should not be affected.

The use of water-binding additives could not be taken into consideration fort two reasons: First, the water discharge would only have been delayed and second a changed chemistry in field of investment casting with its very complex processes would not be accepted. Experiments to accelerate the drying process by using vacuum were not really successful, though the water was extracted surprisingly fast by the vacuum no bound was possible and the shell broke into pieces during the next dipping process.

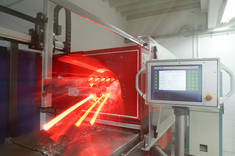

Finally, the breakthrough for the development could be achieved by deliberately ignoring all well known conventional drying rules fort he investment casting. The following logical steps were taken: An extremely turbulent airflow was produced with wind velocities up to 12 m / sec. The tree was slowly and continuously rotating, similar to a chicken in the oven, to achieve a constant flow on the tree. As the high air speed and the resulting evaporation coolness caused a deviation in temperature of the wax of up to 10°C, this effect had to be compensated. The solution for this problem was simple and cheap and originates in the medical engineering sector. Medium wave infrared lights were installed, to avoid the fluctuation of temperature and to preset it at 25-30°C.

As wax and ceramic shells do not only react to super cooling but also to overheating, the airflow had to be air-conditioned to keep the temperature under a maximum limit, as well. Air-conditioning, connected with a bypass to the main current, regulates the shell temperature exactly with a margin of +/- 1 degree. Last but not least, the humidity of the accelerated and conditioned air is additionally kept down to extreme 10-15 % by a dehumidifier.

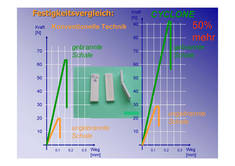

All parameters, especially the chamber and shell temperature as well as the humidity are being controlled by a complex sensor system. The data is sent to a PLC control, which regulates the whole process. The result achieved with key figures far away from the conventional investment casting process was overwhelming. Drying times of so far 24 hours per layer could be reduced to 30 min; a shell with 7 layers was finished in less than 4 hours. And contrary to the well-known doctrine, that an advantage in one field has to be paid with a disadvantage in another one, the effect was vice versa. As a by-product of the new high-speed drying technology the bond became more intense resulting in a stronger shell. A stronger shell can even save one or two layers, increasing the permeability of the shell. This causes a better quality of the cast, especially in the field of the single crystal technology, the supreme discipline of investment casting.

This means that the new development, which was basically meant to reduce the production and delivery times, had several positive effects with regard to increase of quality and cost saving.

A machine for the new technology

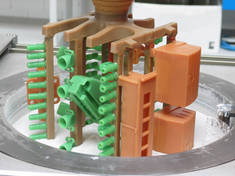

In spite of all the gladness about the successful new development, MK Technology was well aware that a technology by itself would not sell well, so the corresponding machine was developed. As Rapid Prototyping was the main focus, a „mini-factory“ for the fast production of shells was developed, requiring only 4 m². The high-speed drying chamber is the heart-piece of the system. Attached are the two slurry tanks for primary and back-up slurry. On the opposite side there are the two rainfall sanders for the fine and the coarse-grained sand. . The different parts are connected with a linear drive, which brings the tree automatically from one station to the other. The whole system is controlled by a PLC control and a touch-screen with click-wheel and self-explaining software.

From prototyping to series production

The reaction of the Rapid Prototypers on the new development was very positive, as besides the extremely short processing times, this technology allows a perfect cast of all meltable alloys. The processing of titanium, stainless steel and super alloys is now also possible in the field of Rapid Prototyping – this is a kind of revolution. Therefore, the technology has meanwhile been honoured with the „Success“ award of the ISB Investitions- und Strukturbank Rheinland-Pfalz, and the European patent has been issued.

It is needless to say that the conventional investment casting industry also observed this new development. After initial scepticism and hesitation the curiosity predominated, and the new technology was tested. After finding out that the technology works with all wax and slurry materials und that it accelerates the drying by factor 20 the astonishment was great: The most frequent comments were “it is so obvious and so simple” or “Why has no one else thought about it before”. After the prejudices were replaced by enthusiasm, the demand for appropriate machines came up. They should be larger and applicable for prototyping as well as serial investment casting.

Large drying chambers and whole drying tunnels were developed, which accelerate the whole investment casting process with turbulent air, infrared light and dried air, opening the door to Rapid Manufacturing for the entire investment casting industry. The development is far away from being terminated. A couple of new enquiries are received almost every day with new or higher requirements.

While in the early phase of the development MK Technology concentrated on the distribution in the German-speaking countries, the machines are now delivered in the whole world. They are operating in the USA and Canada as well as in Russia, India and China. We would like to finish with the quote made by a philosopher a long time ago: „Nothing is stronger than an idea when the time is ripe for it!”

What is investment casting?

Investment Casting is said to be the oldest known technology to create metal castings. More than 5000 years ago the first bronze cast was made in South-West Asia and India. During and after the 2nd World War investment casting underwent a renaissance. Especially the Automotive, Aircraft and Defence Industry counted on the highly precise metal parts made by means of the shell technology. In Germany the manufacturer of sewing machines, Pfaff, was the first one who rediscovered this technology, and several investment casting foundries were established over here to offer their services.

Investment Casting and Lost Wax Technology – two expressions for the same process which works as follows:

One or several wax parts are attached to a central stem or a casting system. The wax-tree is dipped into a ceramic fluid, the so-called slurry and afterwards sprinkled with refractory sand. The tree resembles an escalope, which has been coated with bread crumbs. In former time, this was done manually; nowadays a computer-controlled robotic arm is applied.

After the sanding process the layer has to dry up to one day before the dipping and sanding can be repeated. Depending on the geometry of the part 7 – 20 layers have to be build. After a final drying process the wax is de-melted in an autoclave by steam and heat. The empty ceramic shell is then burned at 900 – 1.200°C, ready for the cast. After solidifying of the metal the shell is knocked off and the rest is removed in a sandblast cabinet. After separation from the stem and the finishing process the metal part is ready and finally passes the quality check.

With all these different intermediate steps investment casting is a quite complex technology, demanding a lot of know-how and many years of experience. Two parts have to be destroyed, the wax part and the ceramic shell, to get the final metal part. A mistake cannot be discovered before the end of the whole process.

But investment casting is also the technology that allows the production of very precise and highly resilient metal casts. Metals like titanium and super alloys such as chrome-cobalt can only be cast with the investment casting technology.

Suppliers Catalogue: <link>Mk Technology GmbH