In autumn 2010 the company Friedrichshütte GmbH placed the order for a new MF melting equipment with Inductotherm Deutschland GmbH. The time needed to plan the new unit, have it approved and achieve an optimum regarding melting costs compared to the old line frequency unit all in all was two years.

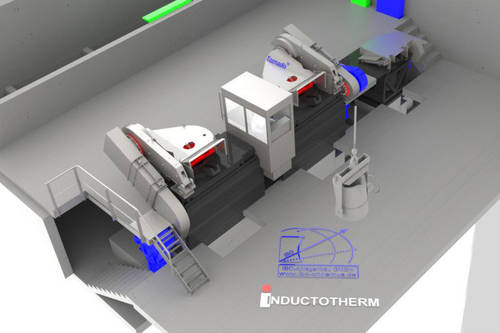

The new melting shop consists of a very complex, compact unit with charge make-up. Due to the conditions on site (hillside) all of that is related to considerable civil works.

Equipment concept

The new melting shop consists of two MF furnaces of the heavy steel shell type with a capacity of 3.000 kg each, designed with all standard safety features like furnace side guard and pushout device. Additionally, a third steel shell furnace with a capacity of 500 kg was installed. All three furnaces are operated alternately with the VIP POWER TRAK having an electrical power of 1.500 kW.

A closed cooling circuit (air/water) is used for the heat losses with the possibility to connect a heat recovery unit.

The entire melt process is controlled by a MeltMinder 200 system.

The installation of the melting shop including commissioning as well as training of the customer´s personnel is part of the Inductotherm scope of supply.

The installation and commissioning is depending upon the weather situation and the resulting progress with the civil works. The commissioning is scheduled for the second quarter of 2011.

The customer´s choice regarding fume hoods is the system provided by IBO Anlagenbau GmbH. The Tornado fume hood is a double-acting system and is capable of catching the smoke occurring during all operation phases.

Due to the possibility to position the fume hood over the furnace and due to its special design energy can be saved and the air quality purified in the working area. The hood allows good accessibility to the furnace during operation as well as for maintenance and repair works. It is operated via hydraulic valves at the operator´s desk.

The hoods were designed specially for the furnaces and the melting operation. The telescope channel of the right hand hood was modified for this project to create sufficient space for the second access to the furnace platform.

IBO Anlagenbau GmbH planned and delivered the pipes to the fume hoods and the transformer room to the filter.

This new Inductotherm melting shop is a landmark for the company Friedrichshütte for an economic melting and safeguarding of the capacities of the moulding line. The small 500 kg steel shell furnace is ideal for new special alloys - a considerable advantage as new markets can be exploited now.

We at Inductotherm would like to take this opportunity and thank everybody at Friedrichshütte and all companies involved for the excellent co-operation.

See you at ![]() GIFA

GIFA

Hall 10 Booth 10B24