At the EUROGUSS 2016 from January 12th to 14th 2016 Foseco will be showing new processes and products for cost effective melting and holding of aluminium, optimized melt treatment and innovative melt transfer and dosing.

Metal Treatment for Aluminium Foundries

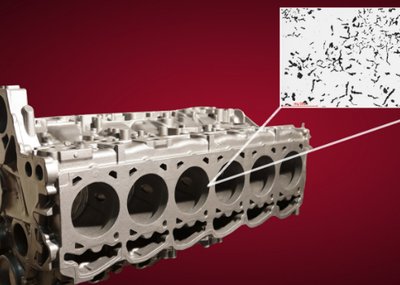

The Non Ferrous metal treatment area will feature the latest generation of Foseco FDU and MTS equipment – state of the art technology for the automated treatment of an aluminium melt. This innovative rotary degassing process is controlled by SMARTT, a software which is based on the recently developed Foseco Degassing Model that accurately simulates rotary degassing. The operator simply defines a melt quality level and SMARTT predicts the best treatment practice based on ambient conditions, melt temperature, rotor design and alloy composition. The treatment parameters are automatically transferred into the FDU MTS. In conjunction with innovative rotor designs Foseco guarantees a constant quality level and reliable results.

A new chemical grain refiner in granulated form can be added through the automated Metal Treatment Station. This new grain refiner offers many advantages such as improved melt fluidity during casting, reduced inclusion level and better mechanical properties. The dross remaining after the treatment is low in metal which additionally saves costs.

Metal Transport for Aluminium Foundries

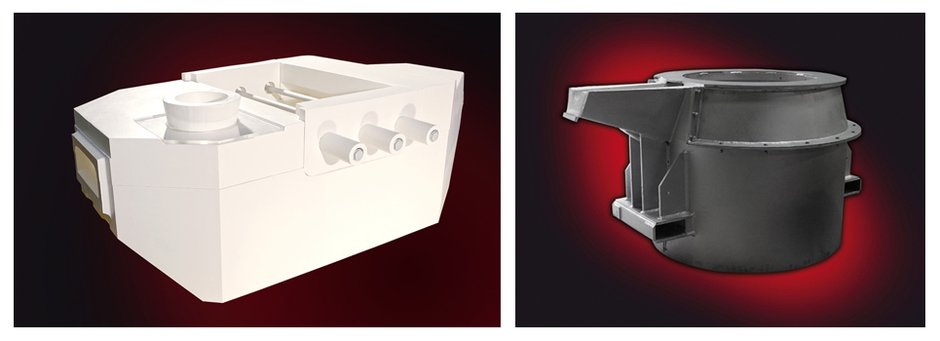

INSURAL Dosing furnace lining

Foseco offers new insulating material for dosing furnaces in Aluminium foundries.

The use of energy efficient dosing furnaces in Aluminium foundries is seen by many as the best available technology today. Foseco is now able to supply a new multi-part and highly insulating lining made of INSURAL, which is delivered ready to install and combines energy savings with long service life and resistance to oxide build-up.

Installation can be made in 3 days with no ongoing hydrogen issues and due to a totally dry installation process no sintering of the lining is necessary. Energy saving can be as high as 17%.

INSURAL ATL transport ladle

The use of transport ladles for liquid Aluminium is common technology in Aluminium foundries. Foseco now offers a fully installed transport ladle system, including the steel shell, a non-wetting insert and insulating backing, in combination with CE certification. It´s unique design prevents melt splashing during transport, even when emergency braking of the forklift truck is necessary, ensuring a safer working environment. In addition to energy saving INSURAL insert provides a high longevity of service.

Partner

Foundry Corporate News

Topic Chemicals

Topic Pressure Die Casting

Topic Low-pressure diecasting

Euroguss 2016

New product applications and innovations from Foseco for Die Casting

Reading time: min

[13]