With the acquisition of the renowned Belgian blast turbine specialist Rutten early this year, Rösler can now offer high-power blasting systems even more closely adapted to specific customer requirements.

|

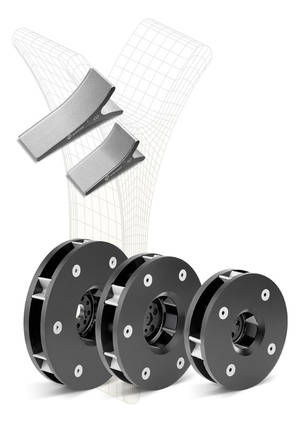

Rutten, for more than 20 years the global leader in the field of long life blast turbines, has always taken a highly innovative approach to the shot blasting business. This has resulted in a comprehensive range of turbines, from the unique designs with curved blades to the revolutionary Gamma-ϒ®-blast turbine that has been proven in intensive tests under the most stringent operating conditions. Numerous patents - especially for the revolutionary Y-active double-sided blades - are proof of the unique high-tech characteristics of the C- and Gamma-ϒ®-turbines.

With this acquisition the Rutten turbines will be fully integrated into the Rösler product range, and the Rösler shot blast division will actively market these turbines to make them available to a wider range of users. Over the next twelve months the Rutten R&D activities and the assembly of the Rutten turbines will gradually be transferred to our headquarters in Untermerzbach.

Managing director, Stephan Rösler, commented: "The acquisition of this small but shining pearl is another step in our strategy to expand our market share in the shot blast market and to offer our customers the best technologies and most economic solutions"

The C - design, blast turbines with curved throwing blades

One of the many advantages of this turbine is that it can throw the blast media with a maximum speed of 130 m/s (430ft/s). This is significantly higher than the throwing speeds of conventional blast wheels resulting in an increase of the impact energy by up to 70% and a considerably better coverage, especially of difficult to reach surface areas. An additional key feature of the Rutten turbines is that their blast pattern can be adapted to the specific customer blast requirements with three different calibrated blast pattern sizes per turbine type: For example, in the case of shot peening applications the blast pattern can be concentrated on a relatively small area. For the cleaning of castings and other general blast cleaning operations, the blast pattern will have a normal size, while for the blast cleaning of large steel plates an enlarged blast pattern is ideal to cover the largest possible surface area on these parts. By using throwing blades made from high-strength alloys, the Rutten turbines are extremely wear-resistant. Furthermore, compared to conventional blast wheels they require less energy and generally reduce the blast media consumption.

Change of rotational direction made possible with active double-sided blades

The most recent Rutten development is the Gamma-ϒ® shape. This design helps to substantially increase the blast area by either manually or automatically changing the rotational direction of the turbine. Of course, the utilization of both sides of the throwing blades also offers the additional benefit of the customer having to stock fewer parts and helps prevent mistakes when exchanging the turbine wear parts.

Thanks to the use of high-strength alloys for their key components, Rutten turbines have an uptime compared to conventional blast wheels of eight to sixteen times longer. Of course, this also results in the pre-accelerator and blast pattern regulator being offered in two different alloys. For example, the critical wear areas of the control cage, namely the cross bars, are also made from a high-strength alloy.

With compared directly with the same sized blast wheel RPM's and diameters, the Gamma-ϒ®-Turbines produce a 25% higher throwing speed of the blast media. This higher speed combined with better flow characteristics and, above all a 70% higher impact energy significantly improves the overall shot blast quality and productivity.

Easy upgrade of shot blast machines in the field

The Rutten turbines, equipped with either direct or indirect drive, and with curved blades or active double-sided blades, are also available for retrofitting to existing shot blast machines in the field.

As an all-round supplier, Rösler GmbH is an international market leader in the production of surface finishing, shot blasting machines, painting systems and preservation lines as well as process technology for the rational surface finishing (deburring, descaling, sand removal, polishing, grinding...) of metals and other components. Besides the German plants in Untermerzbach and Bad Staffelstein, the Rösler Group has branches in Great Britain, France, Italy, The Netherlands, Belgium, Austria, Switzerland, Spain, Romania, Russia, China, India, Brazil, South Africa and USA.