Article also available in <link _top external-link-new-window>![]()

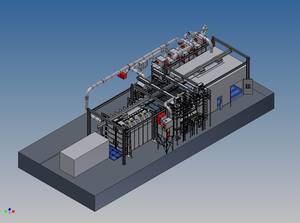

With the installation of a new continuous mono rail hanger blast systemRHBD 35/35-K Rösler pursued two objectives: (1) it provides the urgently needed expansion of the in-house manufacturing capacity, and (2) the new blast system can be used for customer demonstrations and blast trials with large customer welding fabrications.

Rösler designed this blast system for its own welding department in Untermerzbach. It allows the blast cleaning and pre-paint finish of welding fabrications with dimensions of up to 3.5 x 3.5 x 8.0 m (W x H x L) and weights of up to 15 metric tons. This structural blast system is equipped with twenty high performance Hurricane® 15 kW H 42 blast wheels. 2 sets of 2 x 5 blast wheels each are mounted on the left and right hand side of the blast chamber; one set located close to the entrance and one set located close to the exit of the blast chamber. The blast wheels are mounted at an angle of 45 degrees in and against the direction of the parts flow.

This wheel arrangement allows the complete removal of welding slag, scale and rust from the front- and back-side as well the complete height of any welding fabrication irrespective of size and shape. The travel speed of the monorail system can be adjusted from 0.8 – 1 meter/minute. The blast cleaning process itself can take place with the parts transport system moving forward or reverse. For manual post cleaning of fabrications, especially housings with difficult to reach internal areas which may not have been cleaned 100% by the monorail system, a blast room with a compressed air blast system was installed behind the monorail shot blaster.

Parts to be blast cleaned are loaded into the blast system by a gantry crane equipped with multiple adjustable crane elements. Parts can be mounted onto different hanger positions. This allows the blast cleaning of multiple parts in one single pass through the machine. The monorail system is also equipped with a spinner (rotational device) which permits loading of of a batch of many small parts onto a fixture, transporting this fixture into the blast room and blasting the batch of parts while the fixture is rotating.

<link file:7200> |  <link file:7201 download> |

| This structural blast system located in thewith customer parts Rösler welding department expands the in-house production capacity and is available for blast trials | It allows the blast cleaning and pre-paint finish of welding fabrications of up to 15 metric tons. |

Suppliers Profile: <link _top external-link-new-window>Rösler Oberflächentechnik GmbH