The Walter Hundhausen Company in Schwerte has modernised its sand reclamation system. Used sand from the Comessa drum (shake-out drum), excess sand from the moulding system and used sand from the rear bucket elevator are loaded onto a common belt conveyor which transports the sand in the direction opposite to the previous conveying direction and loads it onto a VHV cover belt conveyor.

The Walter Hundhausen Company in Schwerte has modernised its sand reclamation system. Used sand from the Comessa drum (shake-out drum), excess sand from the moulding system and used sand from the rear bucket elevator are loaded onto a common belt conveyor which transports the sand in the direction opposite to the previous conveying direction and loads it onto a VHV cover belt conveyor.

The old reclamation line was guided over various successive, ascending belt conveyors with several transfer points which involved a corresponding maintenance and cleaning effort.

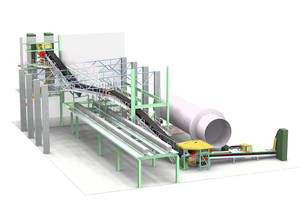

The new conveying route runs from the collecting belt conveyor directly to the used sand bucket elevator and first proceeds horizontally for 3 meters, ascends at an angle of 29 degrees, continues in horizontal direction over the two cooling lines and finally returns to an incline of 35 degrees without any transfer. On its way, it must remain clear of the existing roof truss structure.

The described route is accomplished without any additional belt transfers with a continuous conveyor belt pulled by only one drive pulley.

The terrace-shaped alignment of the VHV cover belt conveyor is implemented by means of flexible drums and a cover belt. Both the transported material and the conveyor belt are covered from the first upward bending station. This ensures closed, safe, dust- and loss-free transportation up to the transfer hood.

Various inclines of between 0 and 40 degrees are possible.

Thanks to their particular design, the special flexible drums, which reverse the cover belt and deflect it in upward direction, allow for completely gentle material transport and a change of incline by maintaining belt tension without pressing the transported material.

Therefore, the throughput of residual metal in the transported material can be implemented safely.

In the ascending section, the cover belt is slightly pressed by pneumatically spring-loaded pressure rollers preventing the transported material from sliding back between the conveyor and cover belt.

The required contact pressure is relatively low and can be adjusted by means of the air pressure gauge.

The discharge of used sand takes place in a hood equipped with an exchangeable flap, which also allows extracting the sand from the system.

As the drive pulley of the belt conveyor is executed as a magnetic drum, adhering residual metal can be safely separated and fed to a collecting receiver via a drop shaft.

After the metal fragments have fallen off, the belt is cleaned by means of torsion scrapers with carbide fittings. The scraped off used sand is also fed to the sand cycle via a drop shaft.

A corresponding collecting tray located beneath the belt conveyor prevents the flasks on the cooling line from being soiled.

It was possible to optimally adapt catwalks, stairs and platforms from the VHV system program to the special terraced layout and the local conditions.

The transfer point of the collecting belt conveyor on the terrace-shaped cover band conveyor crosses under an overband magnetic separator which works in longitudinal direction above the drive pulley of the collecting belt and already sorts out coarse metal fragments at this stage. This process takes place in a separate cased space equipped with a correspondingly shaped cover (hood) which also allows for clean dust removal from this magnetic station.

This way, 300 tons of used sand per hour is returned to the cycle in a particularly effective manner realising considerable savings in terms of cleaning and repair/maintenance costs. Moreover, as only one belt drive is needed for the terrace-shaped cover belt conveyor instead of a number of successive belt conveyors, the system also generates tremendous energy savings.

The system operator, Water Hundhausen GmbH, is constantly seeking to operate its systems in an ever more efficient manner and also does not hesitate to question old established processes. The company is particularly interested in modern, innovative technologies and is ready to implement them.

| VHV Anlagenbau GmbH is a leading supplier. For further information and contact details click here: VHV Anlagenbau GmbH |