ConviTec focuses on plant engineering

The company ConviTec GmbH, Offenbach/ Germany, originally specialised in vibrating machines, increasingly focuses on plant engineering.

A young dynamic team of experienced plant engineers plan and design plants for the foundry industry using the latest programs (3D inventor, Simatic S7 and WINCC, etc.).

The electrical department constructs switching systems according to the latest standards. The respective software (Simatic and visualisation) is developed in-house.

The latest plant was designed, constructed, delivered and installed for the company in Kayseri / Turkey. It is a sand regeneration plant for the biggest available DISAMATIC Type 280 C.

The scope of delivery consisted of a shake-out station with VARIO technology, the entire conveyor belts, magnetic separators, a polygon screen and the sand distribution system above the sand bunkers.

Shake-out feeder „Vario“

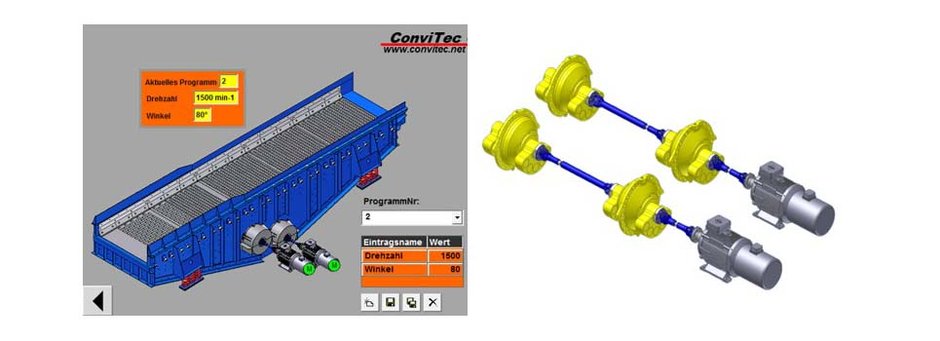

“Vario” shake-out feeders are particularly suitable for shaking out sensitive castings and for different casting programs with small and big castings per order. These shake-out feeders work in the rotational speed range from 1000 to 1500 rpm respectively frequency 16-25 hertz, at an earth acceleration of 4.5 to 5.0 g. Depending on the casting program, the feeders are equipped with longitudinal or transversal slot grids and/or perforated metal sheets. A typical case of application exists where the casted moulds require different shakeout behaviours and adaptation is necessary while production is running. The shakeout behaviour can be pre-selected individually and/or model-related at the moulding plant or via PC of the VARIO shake-out feeder.

For this, the drives (directed exciters) of the VARIO shake-out feeder are electronically synchronized. It is possible to adjust the desired impact angle and thus the conveying speed by changing the phase position as well as the intensity of shaking out by changing the rpm to meet the requirements.

The customer manufactured its own steel construction according to ConviTec drawings.

The plant was successfully put into operation.

×