MRK-Systeme GmbH, with its headquarters in Augsburg, Germany, specializes in industrial solutions that are based on human-robot collaboration. The company enables direct human-robot collaboration – without the need for safety fencing. The 16 employees of the company, which was founded in 2004, work primarily for customers in the field of mechanical engineering, with a particular focus on the automotive industry.

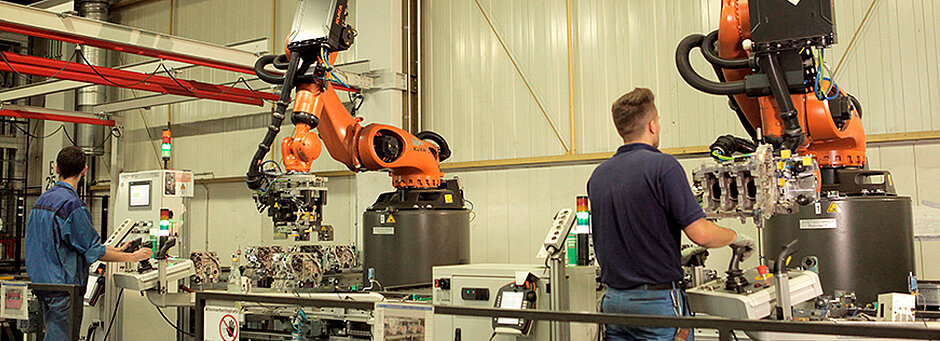

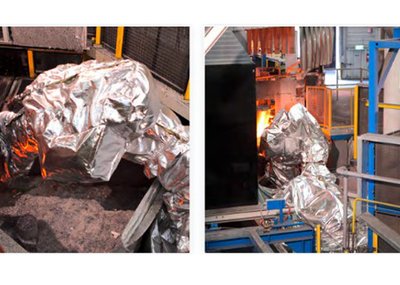

The factory of the BMW Group in Landshut has one of the most modern light-metal foundries in the world. The crankshaft housings for the entire BMW fleet are manufactured in Landshut, irrespective of whether the engines have three, four or six cylinders. BMW wished to automate the process at the factory in Landshut in order to safeguard the quality of the crankshaft housings. This quality assurance process cannot, however, be automated in its entirety. Skilled personnel are still required to keep a watchful eye on proceedings. For this very reason, the assignment issued to MRK-Systeme GmbH was to develop a system in which humans and robots cooperate directly. This safeguards the well-being of the employees, who no longer need to move heavy components. “Human-robot collaboration ensures that the employees at BMW are relieved of ergonomically unfavorable tasks,” explains Michael Mohre, Head of Operations at MRK-Systeme GmbH, who plays a decisive role in the installation of automation systems. For 18 months now, two identical applications have been in operation at the BMW production line in Landshut, Bavaria. Each application includes one KUKA robot of type KR 210 R2900 prime K from the KR QUANTEC series, specializing in high payloads. The K indicates the shelf-mounted variant of the robot. In this application, an employee controls the movement of one robot by means of a joystick in order to maneuver the components into a position that allows them to be inspected for faults without the need for the employee to deviate from a natural posture.

Every crankshaft housing is inspected

Each crankshaft housing that is manufactured is delivered into the workspace by a conveyor. Depending on the design (three, four or six-cylinder engine), the higher-level controller selects the appropriate program to control the movement of the robot. Once the crankshaft housing reaches the robot’s workspace, the worker controls the movement of the robot using the joystick. This sees the robot move towards the housing along a defined path, close the gripper and bring the component to the operator. The worker then inspects the component for faults using a cold light lamp. All the while, the robot securely holds the component weighing roughly 30 kg at the optimum height for the employee. Once the operator has completed the inspection process, he moves the robot with the housing back to the conveyor belt and sets the housing down. The interactive inspection process is then ended by pressing a button. In doing so, the employee documents whether the part is “OK” or “not OK”.

The requirement: to be as safe and as user-friendly as possible

In the case of direct cooperation between human and machine, the safety of the employees is always the main priority. Three mutually independent safety devices ensure maximum safety at the work station. The safety system consists of a programmable logic controller (safe PLC), which also controls the gripper in a safe manner, a safe robot controller, which limits the robot to certain speeds within workspaces, and an enabling switch. The robot cannot move at all unless the employee holds down the enabling switch. If the employee lets go of the switch, the robot stops immediately. Straightforward operator control is also crucial for ensuring that human-robot collaboration (HRC) is practical. The system is implemented in such a way that it is easy for both right-handed and left-handed employees to control the robot. Furthermore, the operator can master the robot control functions intuitively. If the employee pushes or pulls the joystick handle forwards/backwards, the robot moves in a parameterized direction. If the joystick is moved to the left or right, the robot realigns itself accordingly. The height of the crankshaft housing in relation to the worker can also be adjusted using a thumbwheel.

Ergonomics: a decisive factor

Up to now, the quality inspection was carried out using an "aero wheel". The crankshaft housing was rotated using an aero wheel and brute strength so that it could be inspected for faults from all sides. The inherent problem: the aero wheel is heavy. Moreover, tall workers in particular had to stoop over during every inspection which could result in back injuries. The objective was to come up with an application that relieved the employees of ergonomically unfavorable tasks, was easy to control and adhered to the short cycle times required. “Our robots are predestined for the specific requirements put forth by BMW because they can be deployed flexibly. In addition, it is easy to reprogram the robots if changes are made to components. What’s more, they offer good value for money,” explains Mohre, whose company works exclusively with KUKA products. Both of the KUKA KR QUANTEC series robots that are used in the application have a payload capacity of 210 kg. The KUKA KR QUANTEC series, which forms part of the company’s high payload segment, specializes in quick cycle times and the highest level of path accuracy.

Plans to expand the existing system

Both systems have been in operation since 2015. Time to sum up the results: “We have been able to meet all of the customer’s expectations. The cycle time requirements have been met and the employee’ tasks are now far more enjoyable,” says Mohre. Mohre and his colleagues are now working on plans to expand the system. There are plans to install another two quality assurance test stands in order to keep up with the increase in production. “The new applications will be identical to the existing applications with the sole exception that some new features will be incorporated,” Mohre reveals. In addition to the success achieved with this application, the system also demonstrates that collaboration between humans and robots is both useful and safe.

Partner

Foundry Corporate News

Topic Automation

The Dream Team - KUKA robots enable collaboration between humans and robots for quality assurance tasks

Reading time: min

[24]