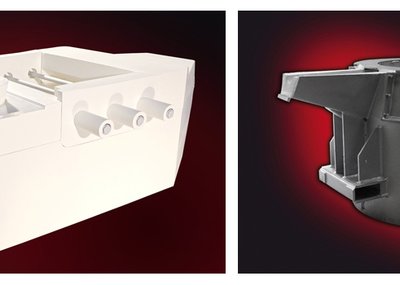

Foseco offers a complete package of lining and purging refractories for coreless induction furnaces melting steel grades (CIF) designed for long life and improved metal cleanliness. Exhibits will demonstrate. The FOSECO Coreless Induction Furnace (CIF) portfolio consisting of high quality KELLUNDITE lining systems suitable for melting a wide range of steel alloys. The incorporation of Foseco Purge Plugs in the coreless induction furnace lining utilizing integral earth protection and precise gas flow control systems to insure safe and optimal operation.

Benefits include:

- Increased refractory life and furnace utilization

- Reduced refractory disposal costs

- Improved casting quality

- Reduced scrap rate

- Floatation of inclusions

- Improved melt homogeneity

- Improved fluidity

Long Campaign Cupola Portfolio for Iron Foundries

Foseco offers a complete package of lining for long campaign cupola melting iron grades designed for long lining life. The FOSECO Long Campaign Cupola portfolio consisting of high quality ramming granular RAMWELL and high quality of low cement castable lining systems enriched with silicon carbide and graphite aggregates to improve the slag resistance. RAMWELL & HYDRA-MAX are suitable for melting a wide range of iron alloys to insure a safe operation of the cupola.

Benefits include:

- Increased refractory life

- Reduced sintering time

- Improved slag resistance

- Reduced maintenance cost