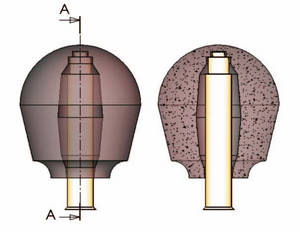

Feeders If you want to prevent the shrinkage that can occur when a cast part cools, HOFMANN CERAMIC feeders offer the ideal solution. This product range comprises insulating and exothermic feeders to meet all requirements.

If you want to prevent the shrinkage that can occur when a cast part cools, HOFMANN CERAMIC feeders offer the ideal solution. This product range comprises insulating and exothermic feeders to meet all requirements.

The unique EXHOF-L feeder and its innovative geometry offer the optimum solution specifically for machine moulding. Only a few sizes cover all application areas. Advantage: Exceptional structure formation.

HOFMANN feeders...

HOFMANN feeders...

- are made from a highly exothermic material with a low fluorine content for iron and steel casting

- ensure high yield

- are ideal even for tricky positioning conditions thanks to their low feeder height

- can be used without breaker cores

- enable you to vary the distance between casting and feeder

- ensure outstanding mould compaction under the feeder neck

- are suitable for all moulding plants

- are non hygroscopic

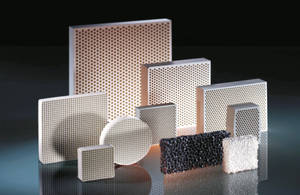

Round-hole filters One of the main causes of high rejection rates are inclusions in cast parts. But this is one area where quality standards can easily be raised. Rely on ceramic filters from HOFMANN CERAMIC, which have been tried and tested many millions of times in practice.

One of the main causes of high rejection rates are inclusions in cast parts. But this is one area where quality standards can easily be raised. Rely on ceramic filters from HOFMANN CERAMIC, which have been tried and tested many millions of times in practice.

We operate our own highly developed in-house tool manufacturing facilities and maintain excellent links with the scientific community. As a result, as well as creating first-class series products, we are also able to customize products to your own specific requirements.

Our pressed, ceramic round-hole filters are produced using an in-house dry-pressing process that is unique worldwide. What's more, they are the only such filters on the market that are stamped “Made in Germany”. Precisely calibrated flow rates ensure your casting processes are homogeneous, and the filters have already demonstrated their dimensional stability and quality for large castings weighing up to 50 t.

HOFMANN round-hole filters...

- can withstand the temperature shock at the feeder head without sustaining damage

- offer non-varying filter porosity

- are deformation-resistant and stable throughout the entire pouring time - minimise non-metallic inclusions

- encourage laminar flow

- are dimensionally stable thanks to a special manufacturing process

- are manufactured in an environmentally friendly process

<link _top external-link-new-window>Click here for more Information and Contact to hofmann CERAMIC GmbH in our Suppliers Profile