"The decision-making processes in the selection of suppliers are very complex. The technological solution alongside technical services and process reliability/ efficiency offered are some of the many determining factors in choosing a supplier."

The editorial staff spoke with Jörg Brotzki, Executive Vice President Europe, to discuss which services ASK Chemicals convinces its customers with.

Under your direction and at a very early stage – nearly ten years ago – ASK Chemicals established an Application Technology Center in Hilden. What were the motives for this?

An integral part of our identity has always been providing our customers with solutions that yield an added technical and economic value.

Our technical sales team provided us feedback quite early on that the market had needs that went beyond pure product application. Customers frequently had concrete questions on topics regarding casting defect prevention, emissions reduction, and process efficiency. For this reason, the management of ASK Chemicals placed great emphasis on the expansion of its technical services offerings including the development of our technology center. At this time ASK Chemicals was unique in this regard. Our technical background allowed us to engage in technical consulting and product development alongside our customer. So early on, we gained an excellent reputation as competent facilitators, consultants, and experts in the field. As the then head of application technology, I had the opportunity to participate in this for many years and I am proud of our achievements and the satisfaction we brought to our customers with the services we created.

Why is this service competence particularly important in the foundry business?

Foundries have appreciated our product portfolio for many years. But we all know that foundry process are highly complex. Operations in the production process have enormous interrelations that must be taken into account. In addition, the economic aspect plays a decisive role in the competitive environment since the growing internationalization of the market has led to an extreme pressure on costs. Product life cycles have been shortened since an increasing number of services and functions are demanded.

Considering the situation, our customers today require a supplier with efficient products, as well as a competent development partner and system supplier. In meeting these demands, we now provide far more services than had initially been imagined. Yet, we had to adapt to the changing market needs to ultimately serve them best.

And how exactly does ASK Chemicals meet these demands?

We support foundries worldwide by examining their entire development and production process and then, working together, introduce a truly value adding solution unique to their situation. However, the implementation is much more complex and depends on the individual task. We have the necessary core competences and resources to achieve this. The entire process works in a close cooperation between the technical sales and the areas of research & development, design services and application technology. Our design services team accompanies the entire process from development and validation up to the prototyping of a corresponding casting. Our designers and engineers possess a profound experience level and understanding of all aspects of foundry technology and metallurgy.

In the Application Technology Center, we operate a test foundry equipped with the most modern equipment. Applications of the latest manufacturing methods are extensively tested there and are analyzed. This is how we develop a reliable basis for risk-free production decision. Our many years of experience in all production steps within the modern foundry industry create the basis for this complete offer.

ASK Chemicals also presents itself as a systems supplier. What does the customer gain from this?

For the customer, process reliability in the production plays an essential role. We are able to entirely serve this demand with our products as well as with our services. We develop processes by means of research, simulation and all other stages of foundry technology production. Of course, the development of solutions can also be undertaken within the framework of workshops.

Ultimately, there is always a solution for the customer that demonstrates cost savings and optimization potentials.

Our teams accompany the customer from the establishment of the task to the finished system. Whether it involves the development of new products, the solution of customer-specific casting defects or even a complex process development – we stand at our customer's side as a reliable partner. Our project successes prove the efficiency of these offers.

Our range of services is rounded off by an individually tailored training concept. Our teams develop the customer-specific training content and then continue the training at the customer's site.

You have accompanied the development of the Application Technology Center at ASK Chemicals from the beginning. How has the range of services developed over the years?

In order to be "state of the art" for the demands of our customers, the capacities of the Application Technology Center have been consistently expanded and further developed in the last nine years. This is reflected in comprehensive investments in simulation programs, a spectrometer, an electric melting furnace for iron, an aluminum melting furnace, a core shooting machine and the recently acquired crane system that all provide us with the basis for the development of efficient solutions. Indeed, the fact that we have used 300 tons of sand in the last nine years as well as 55 tons of iron and 22 tons of aluminum also bears the significance of our Application Technology Center into account.

Fully equipped test foundries are available at the Hilden as well as Dublin (Ohio, USA) sites. The most modern equipment makes it possible to individually adapt the customer’s processes, to develop problem solutions and to systematically advance the development of new technologies and products in very close collaboration with R&D in order to ultimately convey them to the customer's processes. And we will certainly not remain idle here, but will rather continually pursue this path.

What challenges must ASK Chemicals face in the coming years?

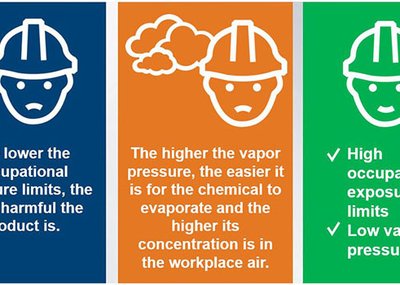

The demands of the 21st century on the foundry industry require a high degree of innovative ability and are characterized by the growing complexity of the castings. In addition, the utilization of the entire value chain and the heightening of the degree of automation are becoming increasingly significant. Electro mobility will influence the dynamics of the foundry industry in the future. Casting geometry – for example, in wind power casting – will further change from the point of view of material efficiency that, of course, will also bring about changing demands on the supplier industry. The issue of the environment is also becoming increasingly important. In our estimation, the compliance with or shortfall of workplace limit values as well as emission guidelines and limits no longer stand behind the economic and technical requirements in their importance. We believe that it is only a matter of time before foundries will increasingly be able to implement "Cradle-to-Cradle" concepts in the sense of sustainable production.

A partnership between foundries and suppliers is essential to mastering all of these trends and challenges. ASK Chemicals is well prepared for these developments and is pleased to stand alongside the foundry industry in partnership.

<link https: www.foundry-planet.com de equipment detailansicht vom-zulieferer-zum-entwicklungspartner-der-giesserei-industrie _top external-link-new-window internal link in current>auch in Deutsch ![]() verfügbar

verfügbar

Partner

Foundry Corporate News

Topic Chemicals

From supplier to developing partner of the foundry industry

Reading time: min

[3]