Predictive Analytics is an exciting new way of using data analytics to increase your equipment uptime. Analyzing data from sensors in your cell in real-time allows us to monitor performance, and using algorithms based on global data, we can then predict potential failures, helping you to avoid costly unplanned shutdowns. Imagine how your production efficiency could be transformed by cutting out unscheduled downtime.

How long does an unscheduled stoppage take?

The machine stops. Your operator investigates. Perhaps spare parts need to be ordered. A technician is needed. Would it surprise you to learn that our data suggests that these stoppages can typically take up to 30 hours out of your uptime?

How can Predictive Analytics help?

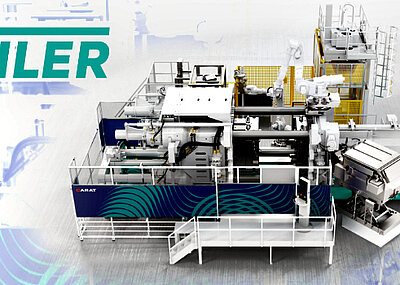

Predictive Analytics is a new way of using data analytics to cut out these stoppages and increase your uptime – an important step towards the 24/7 continuous production goal in our “Digital Cell of the Future” program.

How does it work?

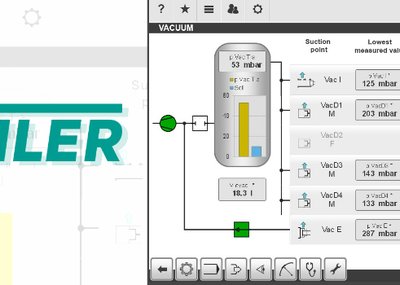

Predictive Analytics works by analyzing data from sensors in all parts of your cell monitoring performance in real-time. The data is collected in your cell management system and our algorithms then analyze the data. Firstly, Predictive Analytics identifies patterns in your data to look for trends and anomalies that indicate certain parts of your cell are not performing as well as they should.

At the same time, using Bühler’s unparalleled knowledge of the die casting process, Predictive Analytics compares outcomes with expected industry results for core elements like the Steady Valve, Shot Cylinder, Accumulator and Pressure Multiplier. Within 2019 we will expand in order to be able to track 10 core elements within the cell.

Taking this data together, Predictive Analytics gives us the ability to spot poor performance and most importantly, to predict potential failures before they occur.

The system can then notify you about the parts of your cell, which may need attention. This gives you the opportunity to eliminate expensive unplanned interruptions, cutting down on stoppage times and helping you to achieve higher consistent quality.

Where is the data analyzed?

Your cell data can be analyzed in the Bühler Cloud or within your own network. Using the Bühler Cloud service enables the algorithms to compare more industry data, resulting in more accurate outcomes.

How much are customers likely to save?

We estimate that Predictive Analytics could help you to gain two and a half production days per year with the first four elements of your cell being measured. And to potentially save on the wasted time and money in slow or incorrect diagnostics.

Part of our commitment to digitization

Within the Bühler group more than 40 experts are working on the topic of digitization. The effort is high but the commitment towards this topic is already showing first successes. Bühler, who is working with the Microsoft Cloud-Platform Azure, was featured as innovative project partner by Microsoft on their booth at the Hannover Messe in May 2018.

When will Predictive Analytics be available?

Predictive Analytics is currently in beta testing and is planned for introduction in 2019.

If you would like to be among the first customers in the world to have the opportunity to review or trial this exciting new development, please do register your interest today.