The 2018 China joint die-casting conference took place in Suzhou on March 20th and 21st. More than 700 participants from 380 companies attended this conference, including China Foundry Association members, government officials, CEO of international companies, and experts of the die-casting industry.

CFA invited MAGMA to actively contribute to this meeting. As silver sponsor, Mathieu Weber, General Manager of MAGMA Engineering Suzhou, collected the award from the Secretary General of the Die Casting Association, a CFA branch. CFA officials expressed their appreciation to MAGMA for their long term support and partnership.

Shoumei Xiong, the respected senior professor at Tsinghua University, Beijing, gave a presentation about “Die-casing technology of the future”. In his opinion, MAGMA’s simulations are a benefit for casting process optimization. The casting competitiveness is improved through in-depth results assessment. Further, Prof. Xiong stated that MAGMASOFT plays a vital role in the development and improvement of die-casting technologies.

Jack Liu, a senior engineer for Die-Casting Applications at MAGMA, gave an interesting report,“From Trial and Error to Intelligent Manufacturing”. The report points out that die casting industry has entered a “post intelligence era” with the popularity of computers and software.

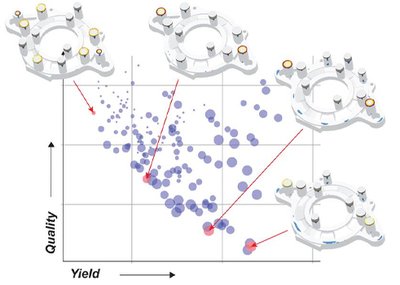

The application of virtual experimentation using MAGMASOFT leads to quantitative results. A rational objective analysis is carried out through the statistics of big data, leading to quantitative results instead of the usual evaluation of qualitative 3D results. By providing an entire overview of the whole manufacturing process, it is easier to evaluate the quality of castings with different criteria, and get a systematic knowledge between production parameters and casting quality standards. Furthermore, one can achieve a robust production process through prospective investigation.

Die casters must have good tools and use accurate simulation software. The software should not only provide a 3D visualization of the flow pattern but also provide a combination of qualitative result assessment and quantitative data. It will help to understand the essence of die casting technology and achieve better result by seamless interaction between software and die-casting experts.

During the two-day meeting, MAGMA had in-depth discussions and shared their experience with experts of the die casting industry. We believe that the die casting industry in China will face additional challenges and new opportunities at the same time. MAGMA and MAGMASOFT are well-prepared to assist die casters for further developments and innovations complying with green and intelligent manufacturing processes.