You identified four megatrends at GIFA 2023 - how would you describe developments a year later?

Till Schreiter: Looking back, we can clearly see that the megatrends we identified are as relevant as ever. It turned out that we addressed exactly the right issues. We recently witnessed this on the Indian market at the IFEX trade fair, and the topic of decarbonization is also driving the economy in both China and America. We also see demographic change on the agenda everywhere – at every company I speak to. It is the search for skilled workers that has everyone on their toes, and incidentally also the retention of skilled workers in the company. Awareness of digitalization is growing: the market now recognizes it as a key driver. I believe that we at ABP have provided a lot of important impetus in the foundry industry in this area in particular – and that is now paying off. We have also seen this in India: customers are discovering that digitalization is a relevant lever. I guess this also has something to do with the presence of ChatGPT and other big AI services: people are realizing what artificial intelligence can really do and that if you want to use artificial intelligence, you have to set up your devices accordingly. As I said, we recognized this early on and provided the leverage for increasing productivity and saving energy with our digitalization tools. And the topic of globalization has also become even more present. For many companies, it is important to expand production in India, for example, in order to be less dependent on China – without turning their backs on the Chinese market, of course. We will have to wait and see what happens in America, with presidential elections just around the corner, and the EU has also shifted its focus more towards its own interests. Added to this are the tensions in the Black Sea region, in the vicinity of important trade routes such as the Suez Canal and other conflict hotspots. The world is becoming increasingly difficult to predict, and you have to position yourself more and more on an individual basis region by region – or be able to afford a variety of approaches. We have moved from the world of efficiency to the world of resilience.

Energy-intensive sectors such as the metalworking industry are concerned with energy procurement, availability, costs and the carbon footprint. What challenges do you see and what do you do at ABP in this area?

Till Schreiter: The topics of energy procurement and CO2 reduction must also be considered in the various markets. The focus on Europe alone makes this an exciting topic. How will nuclear power continue to develop as green energy? What is happening with hydropower? And how do we get hold of the hydrogen that is being proclaimed in many places as the energy carrier of the future? The fact is that we will have to import hydrogen. If we want to continue relying on gas, we will also have to continue importing gas Germany is a country with relatively little sunshine and only a limited number of areas suitable for generating energy from wind. This means that we will always have a relatively high electricity price here compared to other European countries. Countries that have more sun or more wind and can produce their own hydrogen have advantages. And from my point of view, the fundamental question is: what do we want to do with green electricity? I don't believe that we produce our own hydrogen with green electricity. One thing is clear: energy remains a major issue for our customers, and we will have to think about this conceptually and strategically, for example about reducing the number of partial roads in Germany. From my experience, it seems that production is shifting to where it is cheaper. For us plant manufacturers, this means new projects in other countries.

ABP continues to drive digitalization forward – with myABP 2.0, you make it even easier for foundries to maintain an overview of all processes. What are the prospects for the future?

Till Schreiter: I see great prospects here – due to the willingness and the realization that digitalization should not be seen as a singular product, but should be further developed as a community. This creates the kind of partnerships that we ourselves have strived for from the outset – I am very pleased with this development. Our customers, the operators of the large plants, have seen that digitalization can really make a difference, not only in terms of productivity, but of course also as a tool for coping with demographic change, collecting practical knowledge, relieving employees of decision-making processes, leaving process considerations to AI and designing advanced training. Digitalization also plays a role again with regard to energy costs – especially when it makes processes more efficient. Using digital tools to consume less energy not only saves energy, but logically also costs.

How do you meet the challenges on the international market, especially in light of the geopolitical challenges?

Till Schreiter: This is primarily a strategic question, and I think we are well positioned because we have a broad base. We are still present in the important countries, and we will continue to invest in these countries – again, I can point to India as an example. We believe it is important to have expertise in the individual markets and to set up subcontractor structures there. This has been our strategy since ABP was founded – and today it is more important than ever: we have always been a globally positioned company and we will continue to focus on this strength.

Aluminum, steel, heaters, cupola furnace replacements – in which key areas will we see ABP in the new financial year, and what can the market expect?

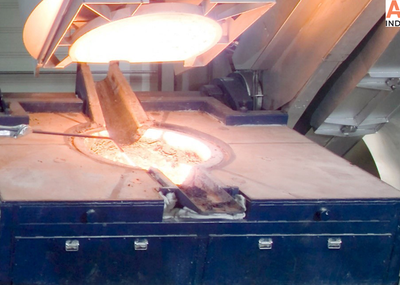

Till Schreiter: We adopted our future strategy last year with a focus on being the partner on the path to 'zero emissions', which means that we want to help change the industry in a sustainable way. This perspective on decarbonization opens up the aluminum market for us, which was previously a classic gas-driven market. We have strong references and customer projects in this area. I assume that this market will develop even faster towards technological changes with a focus on induction than the steel market or the foundry market, simply due to the perceived pressure to convert. Aluminum can be found in many consumer products that require a sensitive approach to pricing in a competitive market. And also in terms of the environmental balance: the younger generation is careful about what they buy, and the expectation of sustainability in the manufacture of products is often right at the top of the agenda. This extends to mobility, from electric cars to aviation and rail transport.

The new Ecoline product line has been launched – what do you expect from this approach?

Till Schreiter: Ecoline is now on the market. We also showcased the product line at IFEX and launched it for the Indian market. We are experiencing strong demand because, on the one hand, the Ecoline's product design appeals to a price sector that may be relevant for customers who want to move from the small foundry to the next step and want to rely on professionalism with the established basic functionality and basic quality of an ABP furnace. On the other hand, we have also designed the Ecoline so that it is easy to maintain and operate without sacrificing expertise. We are already at the cutting edge of essential technology with this line, but it is designed to be easy to use.

ABP is an important part of the group structure of MHI and Primetals – how has the cooperation evolved since the integration?

Till Schreiter: We have managed to build up a very trusting cooperation from which all sides can benefit – for example in the steel sector, where the cooperation with Primetals is very valuable. We have a very close relationship where we work together to develop new concepts, as is currently the case in the heating sector, where we have made great progress in developing new products with Primatals and MHI. The partnership with MHI also opens doors for us beyond the metallurgical environment in order to develop other business areas.

About ABP Induction

ABP Induction is a leading provider of induction melting and heating systems, aftermarket services and digitalization solutions to the global foundry, forging and steel industries. ABP operates through sales, manufacturing and aftermarket locations in the United States, Germany, Sweden, Mexico, Thailand, India, China and South Africa. Since 2018, ABP Induction is part of Mitsubishi Heavy Industries and Primetals Technologies. For more information about ABP Induction, please visit www.abpinduction.com