This week’s edition of Sliced, the 3D Printing Industry news digest features the first ever PMMA-cast public sculpture in the UK, rapid circuit board construction and the 1,000th patient to receive heart treatment with aid of 3D printing.

We also cover Fiberlogy, Robot Factory, Autodesk, Stratasys Direct, BigRep, Reaction Engines, voxeljet, Protolabs and more.

Robust materials and continuous 3D printing

Polish filament provider Fiberlogy has released a new filament called EASY PET-G. This new material caters for those who want the properties of PET and the ease of printing typical of traditional PLA. The filament is made with glycol which ensures high resistance to mechanical, chemical and atmospheric factors. The new filament has also been designed to have good flow which enables prints with greater transparency and better layer bonding. The company claims it improves upon classic PET-G deficiencies: stringing, blistering and filament burning. It will be available to purchase from Fiberlogy distributors from April 2019.

Italian company Robot Factory has announced a higher-temperature version of their infinite 3D printer, called the Sliding-3D PLUS. Sliding-3D printers use conveyor belts to continuously produce volumes of objects. Now in the PLUS upgrade, the nozzle can be heated to temperatures up to 480°C theoretically enabling the extrusion of high temperature materials including those with carbon and glass fiber reinforcement, PETG and HIPS.

Faster circuit board assembly

A new case study from leading 3D printed electronics provider Nano Dimension describes how its DragonFly Pro inkjet deposition system can shorten the end-to-end process for assembling ball grid arrays (BGAs) and other surface mounted components on printed circuit boards (PCBs). BGA’s are found in everything from small devices such as phones and watches, to large vehicles and airplanes, typically take several weeks of complex manufacture and assembly.

Amit Dror, CEO of Nano Dimension, comments, “With the DragonFly Pro, companies can easily assemble BGA components within one hour. This means companies can do everything in-house, with no need for outside contractors, less risk of errors and they can complete complex PCB prototypes without high volume manufacturing processes,” he said.

In related news, TTM Technologies, a California-based supplier of advanced printed circuit boards has also recently invested in two additional DragonFly Pro 3D printers, adding to an existing DragonFly Pro machine at the company’s facility

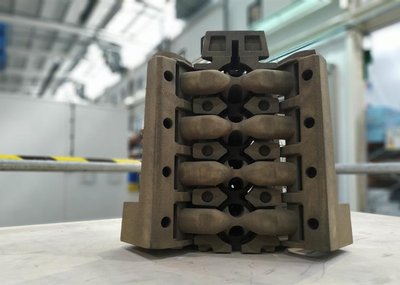

Stratasys Direct, the 3D printing and prototyping service provider of OEM Stratasys, is expanding its additive metals offering with the addition of VELO3D’s Sapphire 3D print system and Flow software. The Sapphire laser fusion metal additive manufacturing system allows for the printing of complex part geometries with in-situ metrology, closed loop control, and low-to-no support structures.

Kent Firestone, CEO of Stratasys Direct commented on the news, “The Sapphire system from VELO3D is an important part of advancing our capabilities to include using additive metals in applications and geometries previously challenging to 3D print.”

3D printings jobs and recruitment news

Autodesk, an American software company, has announced that technology industry veteran Crawford Beveridge will not stand for reelection to the Board of Directors. Beveridge has more than 35 years of experience, 26 of those on the Autodesk Board, with time spent at Sun Microsystems, Scottish Enterprise, HP, Digital Equipment Corporation and Analog Devices, Inc. Commenting on the news that was revealed at the 2019 Annual Meeting of Stockholders, Beveridge said, “It’s been my privilege to serve our shareholders and the company over the past 26 years, which has allowed me to witness the company’s growth from a 2D CAD company to a global leader in design for the AEC, manufacturing and media & entertainment industries.”

In other employment news, German large-scale 3D printer manufacturer BigRep, has named Daniel Büning as its new Chief Innovation Officer. In his new role, Büning will be responsible for BigRep’s technological innovations and prototypes. Büning is co-founder of NOWLAB, a digital technologies and innovation hub which joined BigRep in 2016. Prior to this appointment, he and his team of engineers and designers were the driving force behind the company’s groundbreaking prototypes, including the NERA e-motorbike, the Adaptive Robotic Gripper and the AGV Next mobile industry platform.

In other news, the Bristol based National Composites Centre (NCC) has announced that Reaction Engines, a hypersonic engine manufacturer located in Abingdon, has joined the NCC’s membership network. The NCC focuses on the development of new technologies for the design and rapid manufacture of high-quality composite products. Reaction Engines plans to use the partnership to accelerate its research into ceramic composites for commercial space components, including development of the hypersonic SABRE propulsion system. The company says this partnership will play a critical role in the development of components for the commercial space market.

Advancing and enforcing 3D printing regulation

CECIMO, the European Association of the Machine Tool Industries, has welcomed the introduction of a new classification provision for 3D printing machines. This new product nomenclature standard for 3D printing is part of a system used by more than 200 countries. Maintained by the World Customs Organisation (WCO), this system is technically known as the Harmonized System and is used by authorities to classify goods in international trade and is comprised of about 5,000 commodity groups.

The hope is that this will improve the collection of statistics on international trade of 3D printing machines. The new classification code for AM machines will enter into force from 1 January 2022.

Tangible Solutions , manufacturer of 3D printed titanium orthopedic implants has passed an inspection by the the U.S. Food & Drug Administration (FDA) at its premises in Ohio. The company had its 3D Printing equipment validations and records reviewed, along with many other controls and procedures. The FDA found no violations when it conducted an Inspection. Commenting on the good news Adam Clark, CEO of Tangible Solutions said, “The results of this inspection give our customers another layer of confidence in our capabilities and processes.”

3D printing Collaborations

The UK arm of voxeljet. a global OEM of industrial 3D printing machines and the London Bronze Casting Company, have collaborated to help produce ‘The Green Man’ – a commemorative statue of a former worker (Bill) at a foundry that formerly operated in Deptford, South East London. To create the part, technicians at London Bronze Casting 3D scanned Bill using a photogrammetry technique. The 3D model was then digitally split into casting sections and 3D printed in PMMA on a voxeljet VX1000 PPB printer. The PMMA print sections were then invested in a ceramic shell and cast in bronze to create the final 2.2m tall, 200kg statue – the first ever PMMA-cast public sculpture in the UK.

James Reeves of voxeljet UK, said, “What I really like about the Green Man Project, is that it brings a digital aspect to a very analogue statue. It uses a traditional method of casting, but it’s using the very latest technology to create it.”

Old plastic boards from the UW-Stevens Point’s K.B. Willett Ice Arena in Wisconsin have been donated to CREATE Portage County, a non-profit organisation, to feed its upcoming 3D printer which will be able to use recycled plastic. A large scale system, CREATE’s 3D printer will be able to 3D print objects up to 4 ft x 4ft x 8ft in size.

Saving lives with 3D printing

83–year–old Lillian Keavey, a resident of Michigan, is the 1,000th patient to receive heart treatment with aid of 3D printing technology at Henry Ford Health System. Cardiologists made a 3D replica of Lillian’s heart to practice and design a properly fitting mitral valve, which allows blood to circulate in the heart. Lillian’s procedure was also broadcast for other cardiologist all over the world, so they can learn how to perform the procedure using a 3D model.

Digital manufacturing service provider Protolabs has won the Queen’s Award for International Trade for the third time. The company was one of just 201 companies across the UK to be recognised by the Queen to celebrate her 93rd birthday. It previously won the International Trade award in 2013 and 2010.

You can now cast your vote in the annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook. Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The Green man statue in Deptford, South East London. Image via Richard Smith.

Source: 3dprintingindustry.com

×