ASK Chemicals Offers Significant Value to Foundries

ASK Chemicals will showcase its comprehensive casting expertise and the latest product developments for the foundry industry at Metal + Metallurgy China 2014. ASK Chemicals’ exhibits at this year’s show from May 19 to 22 will be more innovative than ever and topped with its value adding Design Services product line.

The visitors can expect to meet a professional team of foundry experts from China as well as from overseas and to enjoy a professional presentation of innovative foundry resources for all the process steps in a foundry: binders, additives, and coatings for the core shop, filters and coatings for the molding line, and inoculants, alloys, and magnesium treatment by cored wire for the melting shop. The product line Design Services, with its approach from concept to prototype, will certainly be one highlight at ASK Chemicals’ booth, number 2A16 in hall W2.

Design Services: From Concept to Prototype

Design Services by ASK Chemicals provide customers with real added value by optimizing casting designs and manufacturing processes from the initial conceptual design to full-scale production.

From the very beginning of the process, the foundry engineers of ASK Chemicals focus on well-thought-out concepts and thus avoid wasting money, time and raw materials. Companies using ASK Chemicals’ Design Services have accelerated mdevelopment processes and shorter time-to-markets. This design phase is followed by virtual tool validations for which ASK Chemicals uses the most appropriate software solution for the project. This virtual validation is a key element of the process as the well-known testing method of trial and error is eliminated. This process step is crucial when it comes to cost savings and improving superior core quality. Together with its partners, ASK Chemicals offers real support in the design and manufacture of prototype and production tooling and also helps customers to save money and time here related to tooling development.

The ASK Chemicals Design Services product line has the right combination of engineering and simulation expertise, unique alliance partnerships and extensive experience to provide its customers with optimized core and casting designs. ASK Chemicals will be hosting live simulations at its booth at Metal + Metallurgy China 2014.

INOTEC: The inorganic binder solution

ASK Chemicals will be highlighting its innovative INOTEC™ inorganic binder technology in particular, which has already proven its suitability for series production. In addition to achieving an elimination of emissions, this INOTEC™ technology also has a positive effect on the material properties of the casting – a success story that can be attributed primarily to the good interaction between ASK research and customer-friendly implementation. Additional economic benefits are achieved through cost reductions in areas such as air treatment and tool maintenance. ASK Chemicals inorganic binder technology reinforces once more the company’s focus on sustainable and innovative solutions for the foundry industry.

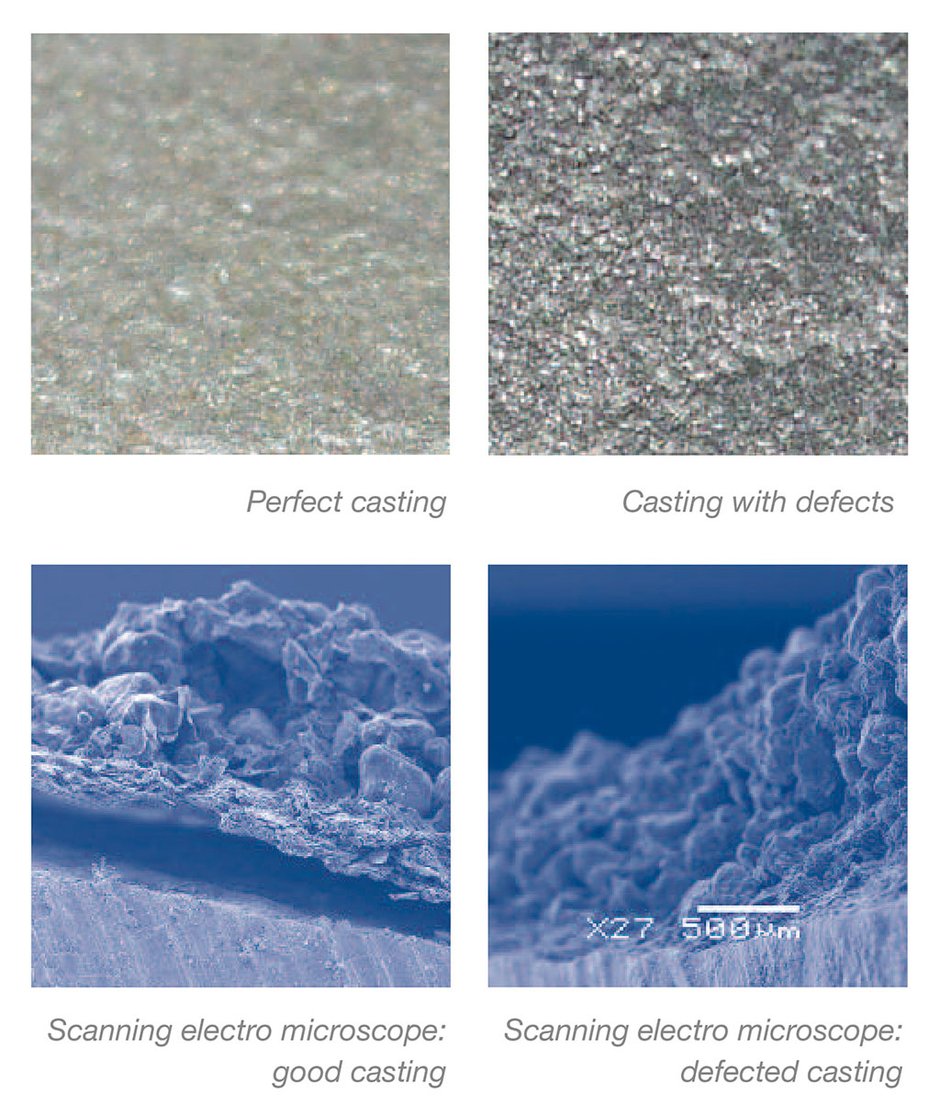

Top surface coatings technology: MIRATEC

OEMs are forcing the foundries to deliver castings with a limited amount of residue in their castings. For motor blocks, these limits could be down to 300 mg per casting. This is to enlarge the maintenance intervals for the cars.

Residues in the cavities of the motor blocks clog the filters earlier and counteract the lower maintenance intervals. Due to the fact that the water jackets or oil galleries are almost impossible to shot blast, there is a serious demand on the coatings to provide flawless castings but also zero adherence of the coating on the casting surface. Therefore, in some cases, a special washing machine has to be installed, which increases costs and reduces productivity. MIRATEC, an innovative coating, provides excellent anti-veining and antipenetration properties, which reduce the coating residue after pouring to a minimum. MIRATEC has already been implemented in foundries to realize those complex requirements successfully in a cost effective way.

Significant value to the foundry market

ASK Chemicals offers significant added value to the foundry – not only through its excellent products but also thanks to its experts, who understand the entire casting process in every detail and according to every demand. ASK Chemicals offers customer-specific solutions by fine-tuning product performance and the casting process in such a way that the specific foundry can produce the required casting quality under most competitive conditions of the foundry setup.

“Thanks to our profound casting competence and our customer orientation, ASK Chemicals provides real added value to Chinese foundries. We strive to form strong and enduring partnerships with our customers – to our mutual benefit,” states Jay Tang, Managing Director of ASK Chemicals in China.

also available in: <link record:tt_news:13882 internal-link>![]()

![]()

###COMPANY_LINK### <link record:tx_browserdirectory_directory:235 internal-link>![]() ASK Chemicals GmbH

ASK Chemicals GmbH