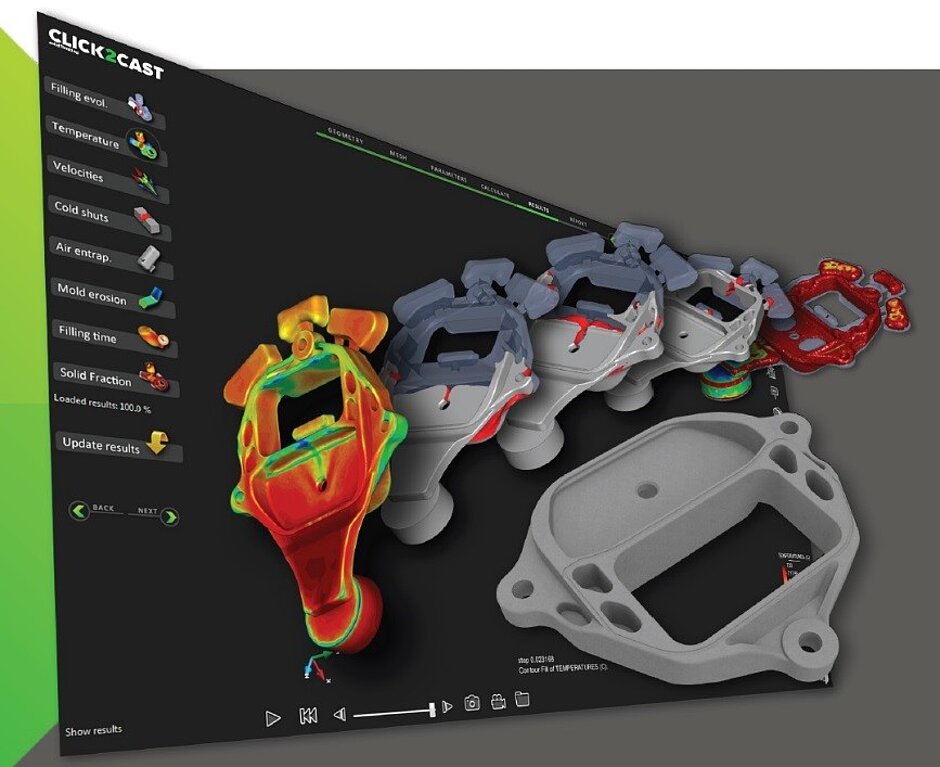

Advanced technology is breathing new life into the most traditional of industries with NovaCast investing heavily in the latest Click2Cast Casting Simulation Systems at its non-ferrous foundry in Melksham.

Richard Phillips, Sales Director at NovaCast commented, "Engineering and simulation software is continually evolving and we need to ensure that we have the most appropriate systems in house. Investment like this is essential in ensuring that UK businesses like ours can continue to compete and prosper in world markets."

He said that gone are the days when the only way to test the integrity of a casting was by trial and modification, albeit in a highly skilled environment.

The new technology allows the design engineers and foundry production teams to model, simulate and test mould designs to identify and eradicate potential issues such as entrapment, porosity and cold shuts well before expensive tooling is created or test castings are run.

The result is faster and more accurate mould designs, greater certainty regarding lead times and lower production costs as design changes due to unforeseen casting issues are greatly reduced.

NovaCast has over 35 years of ferrous and non-ferrous metal casting experience extending into markets as diverse as transport, utilities, offshore and general engineering.

It has particular expertise in the production of pressure-tight valve and industrial pump components, complex non-ferrous castings and a wide range of precision castings for many engineering applications.

Source: engineeringcapacity.com

×