1. School of Materials Science and Engineering, Changzhou University, 1 Gehu Road, Changzhou, Jiangsu Province, 213164, China

2. Key Laboratory of Advanced Metal Materials of Changzhou City, Changzhou University, Changzhou, Jiangsu Province, 213164, China

3. ZhuZhou Nanfang Gas Turbine Packaging and Installation Co., LTD, Zhuzhou, Hunan Province, 412002, China

Abstract: The effect of Ti on microstructure and mechanical properties of Zinc-aluminum (ZA) ZZnAl4Y alloy has been investigated in this work. The results show that Ti addition in ZZnAl4Y alloy refines the primary η-Zn phase and increases the amount of η-Zn+ α-Al eutectic structure. There exists a ternary T phase in Zn-Al-Ti alloy. Fine TiAl3 particles and Ti-Zn compounds can serve as the nucleation sites of the α-Al and η-Zn phase, respectively, resulting in the refining of the microstructure of ZZnAl4Y alloy. Ti addition appears to change the fracture characteristic of ZZnAl4Y alloy. With 0.05wt%Ti, the fracture surface of the alloy shows a lot of dimples and tearing ridges which connected the microscopic dimples. The fracture of the alloy shows mainly ductile fracture morphology. Ti addition in ZZnAl4Y alloy increases the mechanical properties of the alloy. When the content of Ti is 0.05wt.%, the ZZnAl4Y alloy possesses the best comprehensive mechanical properties.

Key words: titanium; ZZnAl4Y alloy; microstructure; mechanical properties

CLC number: TG 146.1+3 Document code: A

Zinc-aluminum (ZA) alloys have good mechanical properties, wear resistance and other properties, such as no spark while collision, no iron residue while melting or die-casting, non-stick and non-magnetism, etc. It is economical to replace copper alloy with ZA alloys. In addition, ZA alloys have low melting point, low energy consume, low cost, and it is suitable for wide range of casting methods [1-4]. For these reasons, ZA alloys possess high competitiveness. Since there are abundant zinc and scarce copper in China, it is urgent to develop and use variety kinds of zinc alloys in industry. The development of zinc alloys can make good use of miner resources and reduce the cost of products. The study and use of zinc alloy is conducive to the economic development[5-9]. In this paper, through the micro-alloying of Ti to ZZnAl4Y alloy, the effect of Ti on the microstructure and mechanical properties of the alloy have been investigated. The optimum content of Ti in ZZnAl4Y alloy has been obtained.

1 Experiment Procedures

When ZA alloys contain the impurities such as Pb, Sn, Fe and Cd, the mechanical properties of ZA alloys will be seriously affected especially the ductility and toughness. So the raw materials used in this experiment are of high purity to investigate only the effect of Ti on micostructure and mechanical properties of the alloy. The raw materials used are high purity zinc (99.99%), industrial pure aluminum (A00, purity of 99.85%), master alloys such as Al-20Mg, Zn-10Mn, Al-30Si and Al-10Ti, respectively.

In the process of the melting of the ZZnAl4Y alloy, there exists melting loss of Zn, Al and Mg. The melting loss rate of the element in Zn-Al alloy can be obtained in literature [10], which is shown in Table 1.

Table 1 The melting loss rate of the element in Zn-Al alloy (%)

Element | Zn | Al | Mg |

Melting loss rate | 5 | 10 | 25 |

The nominal chemical compositions of the test alloys are shown in Table 2. The alloys were melted with graphite crucible in resistance furnace.

Table 2 Chemical compositions of the test alloys (wt. %)

Alloy No. | Al | Mg | Mn | Si | Ti | Zn |

1 | 4.12 | 0.049 | 0.1 | 0.1 | 0 | Bal. |

2 | 4.12 | 0.049 | 0.1 | 0.1 | 0.02 | Bal. |

3 | 4.12 | 0.049 | 0.1 | 0.1 | 0.05 | Bal. |

4 | 4.12 | 0.049 | 0.1 | 0.1 | 0.08 | Bal. |

5 | 4.12 | 0.049 | 0.1 | 0.1 | 0.11 | Bal. |

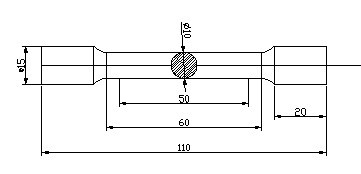

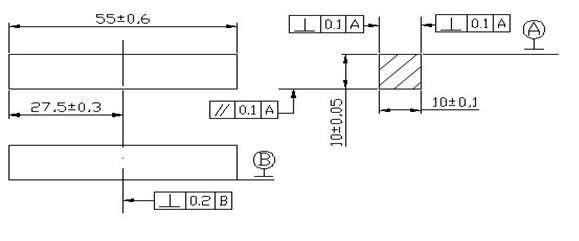

The melting process of the alloys was as follows. First, the graphite crucible was preheated to dark red (about 550℃ ), followed by the addition of pure aluminum and master alloys (Al-20Mg、Al-30Si and Al-10Ti). Then the melt was heated to 700℃. After that, the temperature of the molten alloy decreased down to 600℃. At this temperature, Zn-10Mn master alloy and high pure zinc were added and the melt was kept at 550℃ for 30 min. After the melt was refined with ZnCl2, 5 specimens of Φ15×150mm were obtained by pouring the melt into the metal mould which was preheated to 150℃. For the measurement of the mechanical properties of the alloys, the tensile samples with the size of Φ10 × 50mm (shown in Figure 1) and the impact samples with the size of 10 × 10 × 55mm( shown in Figure 2) were prepared.

The tensile strength and hardness as well as impact toughness of the alloys were measured using Electronic Universal Testing Machine and HBA Brinell Hardness Tester as well as Impact Tester, respectively. Microstructures, morphologies of fracture surface and compositions of the alloys were analyzed by optical microscopy and scanning electron microscopy (SEM) (JSM-5610LV) equipped with energy disperse spectroscopy (EDS). The alcohol solution with 2% HF and 4%HNO3 was used to prepare the metallographic specimen.

Fig. 1 The size of tensile sample

Fig.2 The size of impact sample

2 Results and Discussion

2.1 Microstructure of ZZnAl4Y alloy

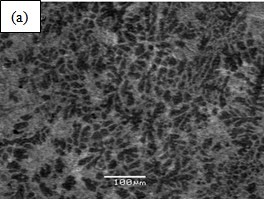

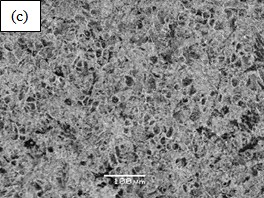

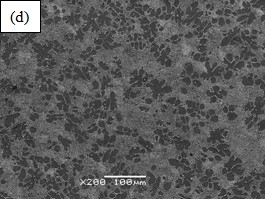

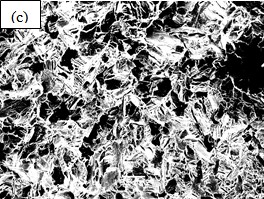

The microstructures of ZZnAl4Y alloys containing different amount of Ti are shown in Fig.3. It can be seen from Fig.1 (a) that microstructure of the alloy without Ti is composed of the primary η-Zn phase (black) and eutectic microstructure (η-Zn+α-Al). The primary η phase exists in the form of dendritic structure. With the addition of Ti in ZZnAl4Y alloy, the morphology of the primary η phase varies considerably. Fig.3 (b) shows the microstructure of the alloy with 0.02wt.%Ti. It can be seen from the figure that the η phase exists in the form of the separate and coarse massive particles. At the same time, the amount of η phase in the alloy decreases. When the content of Ti is 0.05wt.%, the primary η phase exists in the form of small particles as shown in Fig.3(c). Besides, the amount of η-Zn+α-Al eutectic microstructure reaches the maximum. The morphology of the eutectic microstructure of this alloy is shown in Fig.4. It can be seen from the figure that the eutectic microstructure exhibits in the form of fine lamellar. Inside the eutectic microstructure, there exist a few fine black T phase, which will be explained below. When the content of Ti is 0.08wt.%, the morphology of the primary η phase does not change but the size of the phase increases as shown in Fig.3(d), comparing with that of the alloy with 0.05wt.%Ti.

|  |

|  |

Fig.3 The microstructure of ZZnAl4Y alloy with different of Ti

(a) 0.00 wt. % Ti; (b) 0.02 wt. % Ti; (c) 0.05 wt. % Ti; (d) 0.08 wt. % Ti

Fig.4 The morphology of the eutectic microstructure (Ti:0.05wt.%)

The solubility of titanium in pure solid zinc is limited. It can be seen from the Ti-Al and Ti-Zn binary phase diagrams that there exist a series stable compounds with high melting point, such as TiAl3, TiAl2, Zn16Ti, Zn8Ti and Zn5Ti etc. These compounds could promote the formation of α-Al and η-Zn phase, and decrease the grain size [13-15]. There exists fine coherent corresponding relationship between TiAl3 and α-Al. The inter-atomic bonding force at the interface between TiAl3 and α-Al is strong. Small TiAl3 particles could be used as the effective nucleation cores for α-Al. At the same time, the small Zn16Ti, Zn8Ti and Zn5Ti compounds will be the effective nucleation cores for η phase. On the other hand, the promoting effect of Ti to the formation of eutectic microstructure will restrain the growth of primary dendritic η phase. Moreover, some researches [16-18] reported that the Al-Zn-Ti ternary compound in Zinc-aluminum alloys could be effective grain refiner.

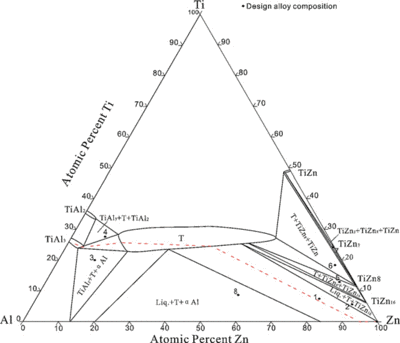

Fig. 5 The Zn-Al-Ti ternary system zinc-rich corner isothermal section at 450℃[19]

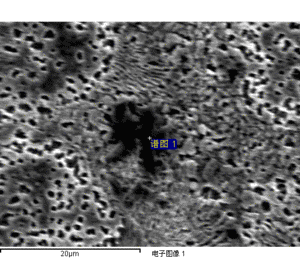

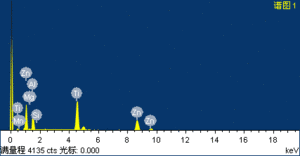

The Zn-Al-Ti ternary system zinc-rich corner isothermal section at 450℃[19] is shown in Fig.5. It can be seen from the phase diagram that a ternary T phase exists in Zinc-aluminum-titanium alloy. In Zn-rich corner of Zn-Al-Ti ternary system at 450℃, there exists a two-phase equilibrium: ternary T phase and liquid zinc. After solidification, the liquid zinc will transform into the primary η-Zn and then the η-Zn+α-Al eutectic microstructure. So the Zn-Al-Ti alloy at room temperature consists of three phases, i.e. η-Zn, α-Al and T phases. The distribution and the EDS analysis of the T phase are shown in Fig.4 and Fig.6. It can be seen that the ternary T phase distributes inside the eutectic microstructure or in the grain boundaries. The T phase existed in the grain boundaries could restrain the growth of the primary η phase. So the addition of Ti into ZZnAl4Y alloy can decrease the size of the primary η phase. When the content of Ti in ZZnAl4Y alloy exceeds 0.05wt.%, the coarse T phase appears as shown in Fig.6, which results in the decrease of the mechanical properties of the alloy.

|

|

Fig.6 The microstructure of ZZnAl4Y alloy containing 0.08 wt.%Ti

and the EDS analysis of T phase

2.2 The mechanical properties of ZZnAl4Y alloy

The mechanical properties of tested alloys with different content of Ti are shown in Table 3. It can be seen from Table 3 that the tensile strength and elongation as well as the impact toughness of the ZZnAl4Y alloy increase with increasing of the content of Ti. The comprehensive mechanical properties reach the maximum when the content of Ti is 0.05wt.%. After that, the mechanical properties of the alloys decrease with increasing of the content of Ti in ZZnAl4Y alloy.

The mechanical properties of ZZnAl4Y alloy are determined by the microstructure of the alloy. The morphology and the amount of the primary η-Zn phase affect the mechanical properties obviously. Because the crystal structure of η-Zn phase is HCP, the phase possesses lower elongation and impact toughness. For ZZnAl4Y alloy, the smaller the size of the primary η phase is, the better the mechanical properties of the alloy are. Besides, with the increase of the amount of η-Zn+α-Al eutectic microstructure in ZZnAl4Y alloy, the tensile strength and elongation as well as the impact toughness increase. When the content of Ti in the alloy exceeds 0.05wt.%, the mechanical properties of the alloy will also decrease due to the existence of the coarse T phase. Considering the mechanical properties of ZZnAl4Y alloy, the adequate content of Ti in the alloy is 0.05wt.%.

Table.3 The mechanical properties of the test alloy

Alloy No. | Ti/ wt.% | σb/MPa | Elongation | ak/J/cm2 |

1 | 0 | 240 | 8.00 | 58 |

2 | 0.02 | 241 | 9.00 | 76 |

3 | 0.05 | 262 | 9.75 | 86 |

4 | 0.08 | 250 | 9.00 | 78 |

5 | 0.11 | 245 | 8.80 | 75 |

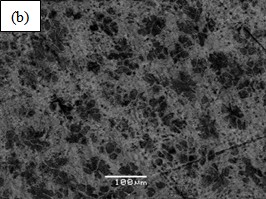

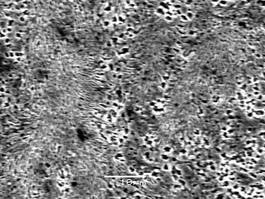

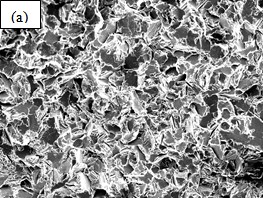

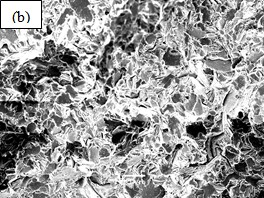

2.3 Fracture behavior observation

SEM images of the tensile fracture surfaces of ZZnAl4Y alloy are shown in Fig.7. The fractured surface of the ZZnAl4Y alloy without Ti is shown in Fig.7 (a). The fracture surface of the ZZnAl4Y alloy shows the existence of dendritic primary η phase. Cleavage fracture which was reflected by the cleavage steps and river pattern can be seen in Fig.7 (a). The brittle rupture is mainly contributed by primary η phase. The addition of Ti in ZZnAl4Y alloy affects significantly the fracture mode of the alloy. When the content of Ti is 0.02wt.%, the fracture surface shows a kind of mixed mode of fracture, exhibiting brittle and ductile fracture. There exist a few dimples in the fracture surface of the alloy as shown in Fig.7 (b). Besides, the fracture surface shows the existence of separate and coarse primary η phase. When the content of Ti is 0.05wt.%, a lot of dimples and tearing ridges which connected the microscopic dimples are observed, as shown in Fig.7(c). Besides, the dimples are the deepest and the biggest comparing with that of the other alloys. The fracture surface shows mainly ductile fracture morphology. This means that the elongation and the impact toughness of the alloy are better than that of the other alloys.

|  |

| |

Fig. 7 SEM images of the tensile fracture surfaces of ZZnAl4Y alloy

(a) 0.00wt.%Ti, (b) 0.02 wt.% Ti, (c) 0.05 wt.% Ti

3 Conclusions

(1) The microstructure of ZZnAl4Y alloy varies evidently with the addition of Ti. When the content of Ti is 0.02wt.%, the primary η phase changes from dendrite to separate and coarse massive particles. When the content of Ti reaches 0.05wt.%, the primary η-Zn phase becomes the finest and the amount of η-Zn+α-Al eutectic microstructure reaches the maximum.

(2) With the increasing of Ti in ZZnAl4Y alloy, the tensile strength and elongation as well as the impact toughness of the ZZnAl4Y alloy increase. When the content of Ti reaches 0.05wt.%, the comprehensive mechanical properties of the alloy is the maximum. When the content of Ti is 0.08wt.%, the existence of coarse ternary T phase results in the decrease of the mechanical properties.

(3) Ti addition changes the fracture characteristics of ZZnAl4Y alloy. When the content of Ti is 0.05wt.%, a lot of dimples and tearing ridges which connected the microscopic dimples are observed. The fracture surface of the alloy shows mainly the ductile fracture morphology.

Acknowledgements

This investigation is financially supported by National Natural Science Foundation of China (No.51074030, 50971111 and 50971110).

References

[1] <link http: www.engineeringvillage.com controller servlet>Shinozaki, Jun, <link http: www.engineeringvillage.com controller servlet>Muto, Izumi, <link http: www.engineeringvillage.com controller servlet>Ogawa, Hiroshi et al. Effects of third element addition on atmospheric corrosion resistance of zinc-aluminum die-cast alloys. Journal of the Japan Institute of Metals, 2009, 73(7): 533-541(in Japanese)

[2] <link http: www.engineeringvillage.com controller servlet>Kubel Jr., Edward J. Expanding horizons for ZA alloys. Advanced Materials and Processes, 1987, 132(1): 51-57.

[3] <link http: www.engineeringvillage.com controller servlet>Gervais, E. ZA alloys-A challenge to the metals industry. CIM Bulletin, 1987, 80(900): 67-72.

[4] <link http: www.engineeringvillage.com controller servlet>Barnhurst R.J., <link http: www.engineeringvillage.com controller servlet>Farge J.C. Study of the bearing characteristics of zinc-aluminum(ZA) alloys. Canadian Metallurgical Quarterly, 1988, 27(3):225-233.

[5] Li Yuanyuan, Xia Wei, Ngai T L et al. Microstructure of a novel high-strength, wear-resisting zinc alloy.Trans Nonferrous Met Soc China, 1995(4):1091-1094.

[6] Jiang Kaiyan, Zhang Guanjun. The applications, properties and development of Zn-Al alloy.Non-Ferrous Metallurgical Equipment, 1995(4):20-22. (in Chinese)

[7] Yan Chengjun, Wang Jidai. Status and application of Zn-Al alloy research.China Foundry Machinery & Technology, 2005(4):4-7. (in Chinese)

[8] Liu Shenbin, Yu Yifan. The development and application of Zn-Al alloy. Materials Review, 1994(5): 30-31.(in Chinese)

[9] Hou Pingjun, Li Huiqiang, Ni Feng. Development of improving the properties of high aluminum ZA-alloy. Development and Application of Materials, 2001(2):31-33. (in Chinese)

[10]Huang Huiyuan. Casting handbook(3) [M]. BeiJing: Machinery Industry Press, 1985: 342-364. (in Chinese)

[11]Liang Cheng, Liu Delong. The several questions should be paid more attention to in quality control for zinc-alloy.Gansu Metallurgy, 2008(6):118-121. (in Chinese)

[12] Vassilev G.P., Contribution to the Ti-Bi phase diagram. Cryst. Res. Technol. 2006, 41(4): 349-357.

[13] Vassilev G.P., Liu X.J., Ishida K. Reaction kinetics and phase diagram studies in the Ti-Zn system. Journal of alloys and compounds, 2004, 375(1-2):162-170.

[14] Gloriant T., Reumont G., Perrot P. Fe-Zn-Ti system at 450°C. Z. Metallkd. 1997, 88(7): 539-544.

[15] <link http: www.engineeringvillage.com controller servlet>Pollard W.A., <link http: www.engineeringvillage.com controller servlet>Pickwick K.M., <link http: www.engineeringvillage.com controller servlet>Jubb J.T. et al. Grain refinement of zinc-aluminum alloys by titanium. Canadian Metallurgical Quarterly, 1974, 13(4): 535-543.

[16] Mondolfo L.F. Aluminum alloys, structure and properties. But-terworth, London, 1976: 354-358.

[17] <link http: www.engineeringvillage.com controller servlet>Abdel-Hamid, Ahmed A. Structure modification of the α′ phase in Zn-Al cast alloys by microalloying. Z. Metallkd. 1992, 83(5): 314-318.

[18] <link http: www.engineeringvillage.com controller servlet>Krajewski, Witold. Phases of heterogeneous nucleation in the ZnAl25 alloy modified by Zn-Ti and Al-Ti master alloys. Materials Research and Advanced Techniques 1996, 87(8): 645-651.(in German)

[19] Yang Sui, Su Xuping, Wang Jianhua et al. The Zn-rich corner of the Zn-Al-Ti system at 723K [J]. Journal of Alloys and Compounds: 2010(3):8-14.

<link>[*] Wang Jianhua, Male, born in 1963, professor. Research interest: Die Casting Zinc alloy.

Corresponding E-mail: <link>wangjh@cczu.edu.cn ;

Su Xuping, Male, born in 1961, professor. Research interest: Die Casting Zinc alloy.

Corresponding E-mail: <link>sxping@cczu.edu.cn