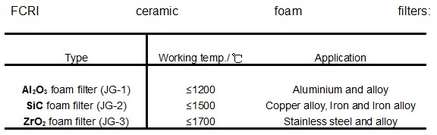

FCRI Ceramic Foam Filters offer the best way to eliminate inclusions, foreign materials that are a major source of quality problems in casting. and help you meet ever increasing demands for quality.

Get rid of the impurity, refractory scrap, solid refractory alloy, sinter, in the molten metal liquid when casting the products, get rid of turbulent flow, reduce the air cavity of castings, help to improve the quality of cast. So our ceramic foam filters (foamed ceramics) are widely used in the foundry industry such as casting /foundry of low carbon steel, stainless steel , iron, bronze, copper, alloy and aluminum for preventing defects caused by oxides, dross, gas, slag and other impurities.

- Eliminates turbulence in the metal stream, Smoothes out metal flow, avoiding sprays, splatter and backset. Improve fluidity, castability, machinability, yield,

- Remove a much greater fraction of fine particulate, Reduce rejects and rework,

- Low-pressure loss.

- Provides consistent flow rate and capacity.

- Various sizes, shapes and pore sizes are available.

###COMPANY_LINK### <link record:tx_browserdirectory_directory:5025 internal-link>![]() FCRI & Jin Gang Group

FCRI & Jin Gang Group