The GIFA becomes more international: The organizers confirm a particularly high demand from Asia for European metallurgy and foundry technology to meet the current demands of the industry for energy and resource savings. The company Laempe Mössner Sinto, a global leader in the field of core shop technology, can confirm this trend: "Among the nearly 2,000 visitors at our 500 square meter booth were many decision-makers from the Far East, who could convince themselves of the strong innovative ideas which pervade our entire product portfolio“, said CEO Andreas Mössner, who used the GIFA also for reporting the new partnership his company have entered: The listed Sinto Group from Japan, the world's largest manufacturer of foundry equipment, has acquired a minority stake of 40 percent in the family business. The company is now operating under Laempe Mössner Sinto GmbH. The partnership with the globally operating Sinto Group allows direct access to production sites worldwide and new sales opportunities in various markets, particularly in Japan and emerging economies.

"The first big appearence under a different brand name at the main trade fair was a great success," said Mössner. "The trade visitors from all over the world have recognized and encouraged us in our ongoing internationalization efforts."

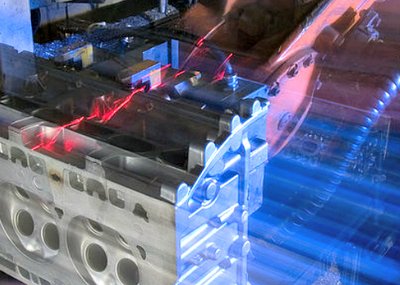

The booth of Laempe Mössner Sinto on the product side was under the Motto of saving resources and efficient production. Among other exhibits presented was a lab machine up to high-performance core shooters and other inovations, on the one hand to satisfy the increasing demands for tool weights and precision guidance, on the other hand also allow easier operation and an optimized control technology. These included the "L1" as a multi-process lab machine, an „LL20“ with an extensive facelift consisting of improved carriage and table guides, as well as table and side part transducer measuring system. The core shooter „LFB 25“ with facelift (rotatable top part for optimum cleaning and maintenance of the core box, integrated high performance gas generator LGi, measuring sand level in the fixed shoot head) and the fast, energy saving, high performance core shooter „LHL 30“ shown in combined Coldbox and Inorganic configuration. Also on show was the mixer „LVM 5“ with the new sand-, additive and binder dosing systems and „LVM 15“, the new high capacity mixer for all binder sand processes, the „LGi“ gas generator with energy optimized heater and high precision catalyst dosing, and the „LDA“, the Data analysing-Tool from Laempe with the new Diagnostic-Software.

"The show has clearly demonstrated that industry 4.0 also in the foundry is the major issue," says Laempe CEO Andreas Mössner. "It is about highly reproducible, documentable processes and in the light-alloy foundry the main topic is the inorganic binder process."

Photos: Laempe Mössner Sinto / Elke Schmidt