What do Fucoli -Somepal cast?

Fucoli-Somepal is a foundry company with 2 foundries established in 1998 by the merger of Fucoli (founded in 1946) and Somepal (founded in 1957).

The main cast iron products of the company are as follows:

- Manhole covers, gratings, reducers, hydrants, pipes, pipe fittings and joints;

- Gate valves, swing check valves, globe valves;

- Gray and ductile iron castings according to the customers' requirements.

What have been the biggest challenges?

Definitely more competition from near and far means we are chasing fewer orders with more intense competition. This results in lower prices per casting but with higher quality and faster delivery requirements

Fucoli –Somepal have invested heavily in Koyama Automatic Grinding Machines over the last 2-3 years. Is this in response to the above challenges?

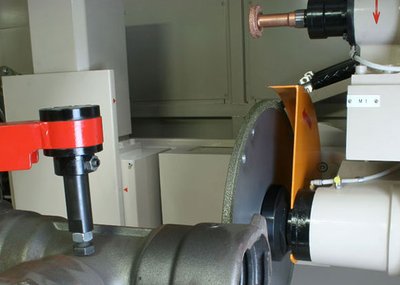

Yes, the only way we have found to reduce cost and match grinding output with production capability is by using Automatic Grinding Machines. On average the system is four times faster than manual workers with 100% repeatability that eliminates inspection and all of the re working resulting from poor grinding.

After extensive research we chose Koyama, distributed by PS Auto Grinding from UK, and have been so pleased with the results that we now have 5 machines in total

Why did you choose Koyama?

Firstly it had a huge track record of foundries in Europe that were having great success with the machine. These Japanese machines were in general running 23 hours a day, with almost perfect reliability and consuming little in spares.

At the time of our first purchase there was no reason to think that we could not get 15 to 20 years of very efficient life out of these machines with a little care and attention.

The fact that our non skilled labour could program, operate and fault find after just a few hours training was vital.

Programs can be made ‘production ready’ in as little as an hour and fixturing is simple, fast and cheap.

The design of the Koyama is such that we estimated that over 95% of our production could be ground 100% by the machines.

Now we have 5 machines.

With labour relatively cheap in Portugal by comparison to some Western Europe regions have the financial benefits been good?

With manual grinding we often fell behind in the grinding department, having bottle necks or back logs that put great pressure on deliveries and that affected the whole business.

Because the work is so hard, finding and keeping people to do the work is not easy so the result is usually a fairly unexperienced workforce. This means that quality is difficult to maintain without rigorous training and inspection processes and we need extra capacity to re work castings that maybe accounted for 10-20% of all castings.

So, if you calculate on a simple replacement of labour basis the return is good but as a businessman you take into account the true costs of all the recruitment, training, inspection, and supervision it becomes one of the best investments in our foundries.

Now my grinding costs, quality and productivity cannot be bettered by any foundry anywhere in the world.

Almost as a bonus, the finish from the grinding by the Koyama machines is far better than hand grinding so castings are presented to a higher standard, even prototypes.

What effect has this had on customers?

Customers are becoming more aware that Fucoli –Somepal have the lowest cost, fastest and highest quality processes in grinding and the significance this means to them.

One of the largest barriers to increasing orders is to increase grinding by the same amount but customers now have confidence that we will simply increase the usage of the machines and/or buy new machines.

Winning new customers is another factor. Top performance with existing customers gives confidence to new customers, including excellent value for money, delivery deadlines met and high quality standards.

Better appearance of a casting is also proving to be important when decisions are close with competing foundries.

We have also found that customers visiting the foundries are impressed with the clean, quiet, efficient grinding departments rather than the usual noisy, dirty, and dangerous departments. It fits in with their own Safety and Environmental policies.

Has there been other benefits?

Working in the grinding department is now in demand and negative factors such as absenteeism, staff turnover are now the same as any other department.

Accidents are almost nil, as all grinding is enclosed in the machine.

We now do not have to manage EU legislation so much in relation to Noise, Dust and Vibration.

We now use considerably less consumables for grinding as one diamond wheel can last 000’s of castings. This saves money and time in abrasive changeovers, storage and replenishment.

The size of the machines is roughly equivalent to one hand grinding bench so the area needed for grinding is much smaller. Also, the Koyama machines have eco servo motors as standard so energy consumption is far less than with a manual grinding department

Thank you for your time, do you have any final thoughts?

Assuming that most foundries have modern and efficient casting processes in melting, moulding, core making etc. in place nowadays why ignore the largest, and most problematic department in the foundry, in terms of labour and cash demands?

The impact of around 50% savings in grinding costs from Koyama machines has made a huge difference to the competitiveness and profitability of Fucoli-Somepal but has also made our job much easier and simpler.