PS Auto Grinding Limited, market leaders in Automatic Grinding Machines, are becoming established as a proven solution to the combined cutting and fettling of Aluminium Castings in non- ferrous foundries across Europe.

Perhaps more known for grinding of Gray and Ductile Iron castings with machines working currently in 16 European Countries, grinding more than 50 Million castings per year, PS Auto Grinding Limited has developed a solution for Aluminium foundries that;

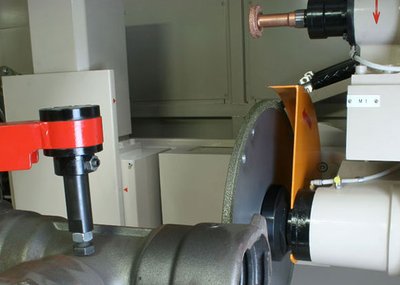

- Makes the Cutting and Fettling a one station operation

- Is often faster by 3, 4 or 5 times than traditional methods but requires less labour and material handling

- Safer, with the elimination of band sawing and reduced vibration from hand grinding castings

- Better because each casting is ground to the same accuracy producing less reworking and reduced inspection needs

- Creates a much better working environment leading to lower levels of absenteeism and staff turnover

PS Auto Grinding Series 400 & 500 for Aluminium offers the same key benefits that all PS Auto Grinding customers receive;

- Simple, non-skilled programming requiring no previous programming experience. Zero knowledge to capable in 3 days

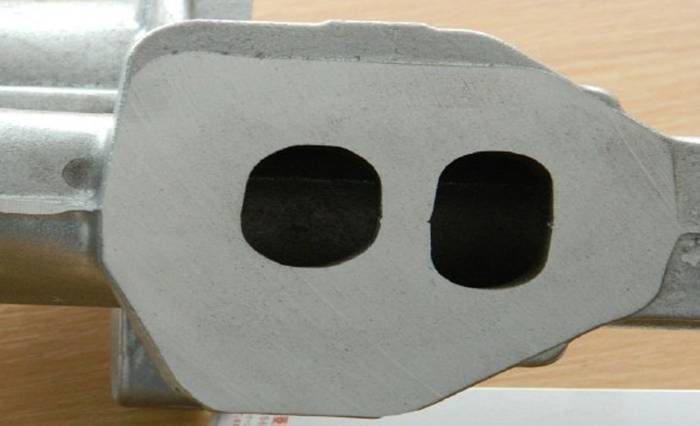

- Unique to Series 400 & 500 Tilting Wheels meaning that 95% of all castings can be ground 95%.

- Fixtures are non- precise so costs are substantially lower than precise fixtures for CNC and Robotic systems

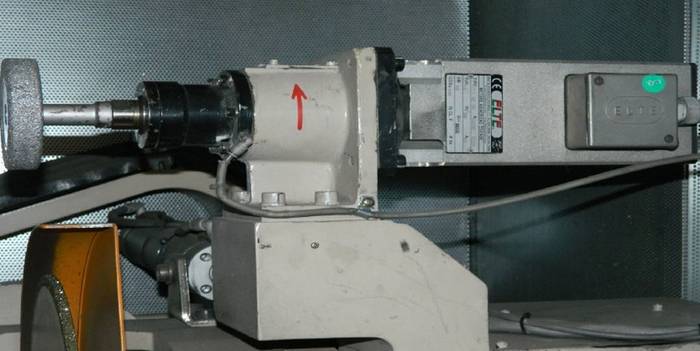

- Very strong reliability from the Japanese technology with around 3000 machines worldwide.

- Long Life in the region of 15-20 years on 3 shifts anticipated

- Payback almost always under 2 years

- Small space requirements when replacing 3, 4 or 5 combined cutting and fettling workstations

- Elimination of band saw accidents, eye and hand accidents from using grinders and elimination of repetitive strain injuries known as Vibration White Finger or Hand Arm Vibration Syndrome (HAVS)

Strong Sales in Aluminium Continue

PS Auto Grinding Limited sales success in Aluminium foundries has continued in 2013 with the confirmed deal to supply MGG Tegelen B.V with their second machine to be installed later in 2013

MGG Foundry employs 500 Workers

This follows on quickly after another recent successful installation at Aluminium foundry Charter Castings in UK. Ing. Will Briels, Manager Operations MGG Tegelen B.V said after placing the order. “It was one an easy decision to buy another PS Auto Grinding Series 500 for the foundry. The 1st machine has performed excellently and the back and service from PS Auto Grinding has been very good. Not only do they respond when we need them they are willing to work beside us in optimising the performance of the machine. For a 3 shift large foundry working flat out any increases in productivity can have significant impact. “

Listening to Customers Pays Dividends

Paul Smith, Managing Director, PS Auto Grinding Group states “ PSAG identified that significant savings for Aluminium Foundries could be had, as well as, a far safer method, and the repeatable quality increases in fettling that PSAG machines give over hand grinding.”

Band Sawing, Potentially Dangerous Operation is Eliminated

Paul Smith continues “It is also good to see that many Aluminium foundries such as MGG also see that the PS Auto Grinding process, cutting gates and feeders as well as fettling in one cycle, is more commercially and technically interesting than other solutions to the problem, such as Robotic Fettling Cells”

Repeatable Excellent Grinding Quality

Paul Smith adds; “What we did not envisage was how the repeatable accuracy to 0.1mm would have on the machining process, reducing time and cost in the final preparation of castings, and how much energy would be a factor. The high efficiency servo motors are a considerable benefit in running costs against traditional methods.”

High Efficiency Servo Motors are Standard on all Series 400 & 500

Simple Feasibility Studies

PS Auto Grinding have developed successfully a quick and effective system to allow foundries to work out whether PS Automatic Grinding Machines are technically suitable and whether the commercial benefits make sense for the foundry.

Trials of up to 2 Castings are free from PSAG with Video

It is through this process that companies such as MGG can trial their castings, compare the speed and quality against their current processes and get their calculators out to determine that the financials are right for them. This ‘no pressure, no cost’ approach’ appears to suit our customers who often have many competing decisions to make and welcome the professional support we give.