Rassini is the world’s largest producer of suspension components for light commercial vehicles, producing 2,200 brake discs per hour. With a consistent focus on technology and engineering development, the Mexican foundry remains at the forefront of innovation. At their facility in Puebla – just a two-hour drive from Mexico City – Rassini has built what DISA refers to as ‘a complete foundry’. There, every machine throughout the foundry operations is delivered by DISA – from moulding to shake-out and casting, to sand, cleaning and extraction.

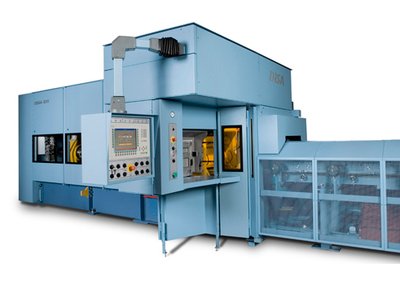

“With the installation of the new DISAMATIC D3, I expect that Rassini will reach a monthly capacity of 1 million brake discs”, says Héctor Galván Venegas, CEO of Rassini in Mexico, thereby setting the scene for the introduction of the Rassini and DISA year-long partnership and for an in-depth description of how the DISA moulding lines have resulted in a 63% productivity gain and only 3% total scrap with a 98% uptime at the Mexican foundry.

Long-term relationship, reliability and trust

“We’ve been working with Rassini for a lot of years and have established and maintained a good supplier and customer relationship”, says Roberto Ramirez, Senior Account Executive at DISA Industries Inc.

“Rassini uses a high density vertical moulding process, and the most reliable equipment to carry out this process is the DISAMATIC moulding line”, explains Victor Miguel Sanchez, Process Engineering Manager at Rassini.

Customer and market insights

“We have three smelting plants. We have a machining plant, three painting plants, and one plant with a special heat treatment process, ferritic nitrocarburizing”, Victor Miguel Sanchez continues.

“Having a long history with Rassini throughout the years of their DISA installation has also allowed us to provide a better technical service, because we understand the customer; we know about their development history, and where they are going – and all in all, this has helped us to find the best way to provide solutions for their maintenance and future needs”, says Roberto Ramirez.

Technical support and maintenance

“DISA provides all the necessary training. A crew of technical service engineers work onsite with the customer to make sure that all the installations are done correctly. We also handle the operation and maintenance guidelines”, Roberto Ramirez explains.

“The DISA team is important to Rassini, because they offer the necessary technical support to maintain the machines in good condition. The communication is remote, and they don’t need to be at the plant, because they have access to our machines. Also, they provide everything related to the replacement parts needed to ensure that the machines stay in good condition”, concludes Victor Miguel Sanchez, Rassini.

Future plans

“As part of the future plans, Rassini will install a D3 machine – one of our newer-version machines, which will allow them to expand their range of castings to be more productive and have the versatility they need for the automotive market. This new line will tie into the existing system, which helps, because it will allow Rassini to keep producing instead of having a large shot-down. As such, they can continue with their production plans, while we work on adding the new machine”, Roberto Ramirez explains.

63% productivity gain: A strong and well-running foundry business

Superior quality, tailor-made technology and integrated services allow Rassini to maintain loyal relationships with their customers. As they continue to push the limits of technology and innovation, they will continue to rely on DISA to keep the wheels of industry turning. Lowering their costs per casting and keeping their business running strong – already having achieved a 63% productivity gain and only 3% total scrap with a 98% uptime.

Partner

Foundry Corporate News

Topic Moulding

Topic Machine mould casting

Neuste Videos

Rassini Foundry - At the forefront of innovation – with DISA

Lesedauer: min

[19]