The new software RobotStudio Machining PowerPac is designed to ensure easy robot programming, and is the key to optimizing the potential of automated machining.

RobotStudio uses an exact copy of the real software that runs robots in production, so realistic simulations can be performed, using real robot programs and configuration files identical to those used on the shopfloor. Time and risks are reduced by programming robots offline, in addition to more accurate paths being created.

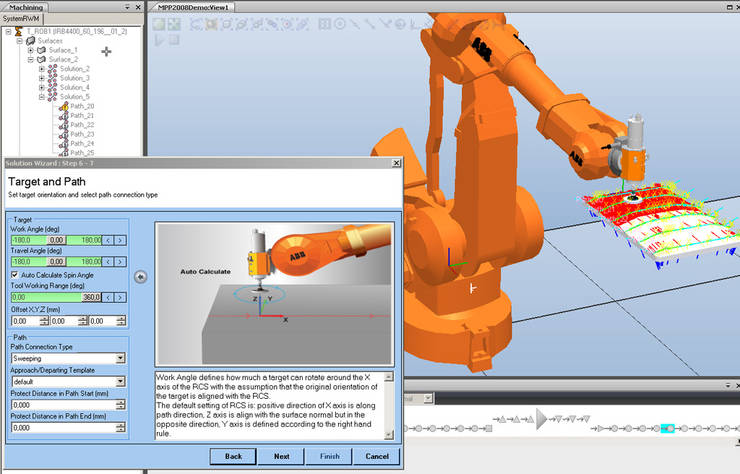

Using the Fluent user interface from Microsoft Office 2007, the RobotStudio Machining PowerPac features an intuitive wizard to guide users in creating targets and paths from surfaces and edges quickly, easily and accurately. Pre-defined path generation patterns are provided to support all possible machining types.

All process settings such as tool width, overlap rate, machining angles, etc., can be defined in different pages of the wizard and used to generate the targets and paths. In the last wizard page, a preview is provided to show how the paths look like before they can be finally created.

The Power Pac includes three machining templates as default: NormalProcess, FC (Force Control) PressureProcess and FC SpeedChangeProcess. All of the parameters in the templates can be customized and re-used among different cases.

Because the Machining PowerPac supports force controlled processes, it works seamlessly with ABB’s software for force controlled machining, RobotWare Machining FC, and the program generated in Machining PowerPac can be imported into and recognized by RobotWare Machining FC.

RobotStudio Machining PowerPac is an add-in to Robot Studio, which makes it possible to create complex paths in just seconds!

RobotStudio 5 is the leading product for offline programming on the market. With its new programming methods, ABB is setting the standard for robot programming worldwide.

Creating complex paths in just seconds with wizard.

For an imported CAD model, an intuitive wizard can guide a user to create targets and paths from surfaces and edges easily, quickly and accurately. Pre-defined path generation patterns are provided to support all possible machining types. All process setting such as tool width, overlap rate, machining angles, etc. can be defined in different pages of the wizard.

Altogether there are 7 wizard pages. Each page is intuitive with graphical and text explanation of the key functions in the page, that enables the quick use and follow up of the process wizard.

By using RobotStudio Machining PowerPac you get increased engineering efficiency

- Reduce programming time

- Engineering and commissioning efficiency

- More cost efficient handling of short batches

- In control of the process parapmeters

- Easy to create and modify robot parameters

- Improved path accuracy

- Seamless integration with RobotWare

Features

- Path programming wizard

- Create/select surface or edge to be machined

- Set machining process parameters

- Pre-defined path generation patterns

- Set path and target parameters

- Path and target optimization and modification

- Path simulation

- Program export as RAPID or RW Machining FC

- Calibration

- Pre-defined and configurable machining templates

- Check/heal CAD models

Suppliers Catalogue: <link _top>ABB Robotics