Information

Founded in 1973, ESI Group envisions a world where Industry commits to bold outcomes, addressing high-stakes concerns - environmental impact, safety & comfort for consumers and workers, and adaptable and sustainable business models. ESI provides reliable and customized solutions anchored on predictive physics modeling and virtual prototyping expertise to allow industries to make the right decisions at the right time while managing their complexity. Acting principally in automotive & land transportation, aerospace, defense & naval and heavy industry, ESI is present in more than 18 countries, employs about 1,000 people around the world, and reported 2022 sales of €130 million. ESI is headquartered in France and is listed in compartment B of Euronext Paris.

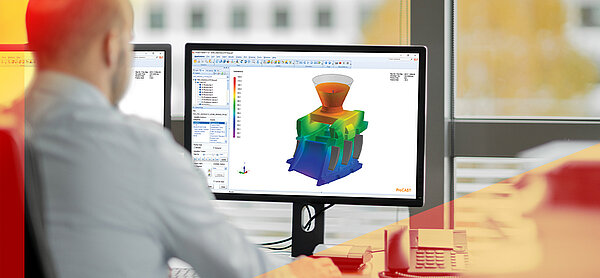

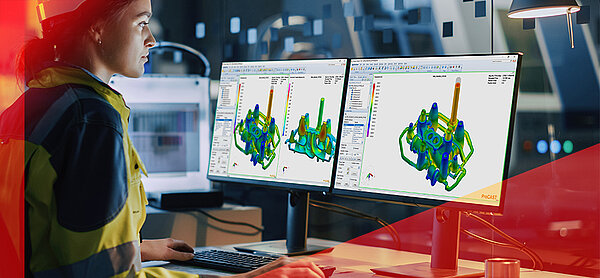

ESI’s casting simulation software ProCAST is designed specifically for foundries and toolmakers, offering reasonable pricing and flexible licensing options. ProCAST is tailored to casting product and process development and significantly reduces shop floor trials. Foundries can then achieve their pre-production prototype on the first attempt, ultimately increasing productivity and efficiency, while ensuring delivery on-time and in the required quality.

- With over 30 years of excellence, ProCAST offers intuitive casting process simulations that capture filling, solidification, and cooling seamlessly.

- Foundry tailored workflows simplify even the most complex simulations, and advanced process modeling capabilities allow for mastering sand casting, investment casting, and die casting processes.

- ProCAST features comprehensive material and thermodynamic databases that capture thermophysical properties for various casting materials, as well as thermos-mechanical properties based on your chemical composition.

- Advanced precipitation modeling ensures the right level of accuracy for cast iron.

- Users virtually assure quality by making informed decisions based on basic and advanced defect analysis. They predict, for example, any kind of porosity, air entrainment, mold erosion, cold shut/misrun, cracks, stress, distortion, oxides, surface defects, and microstructure.

- Foundries can leverage ProCAST casting simulation capabilities with high-performance computing power from the cloud, accommodating their scalability and cost needs.

ProCAST is trusted by foundries, suppliers, and OEMs globally for achieving first-time-right quality and efficient casting processes.