Information

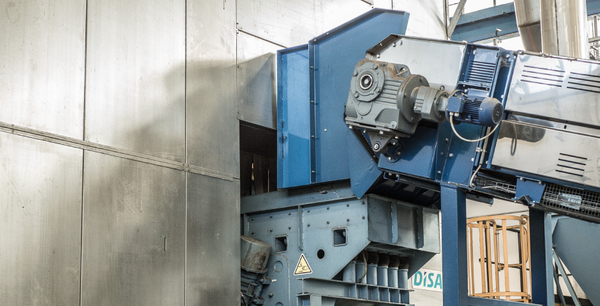

Since 1929, the Magaldi Group has been at the forefront of developing innovative, reliable, and sustainable solutions for material handling in severe operating conditions.

Trusted worldwide - particularly in the metalcasting sector - Magaldi combines nearly a century of experience with continuous innovation to deliver systems that maximize efficiency, safety, and environmental performance.

At the heart of every Magaldi solution lies the proprietary Superbelt® - a unique steel belt conveyor featuring a multi-link, damage-tolerant design, engineered to ensure superior durability and minimal maintenance, maintaining smooth operation even under extreme conditions of high temperature, heavy loads, dust, and abrasive materials.

Magaldi’s engineering expertise serves both ferrous and non-ferrous foundries, covering a broad spectrum of applications, including:

- Scrap charging and preheating

- Mold dump conveying

- Mold cooling

- Hot sand conveying

- Casting cooling

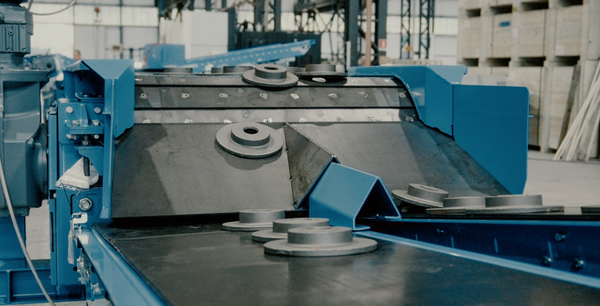

- Casting degating and (automatic or robotized) sorting

- Crusher feed and out-feed

- Blast casting handling

Each solution is tailored to integrate seamlessly into existing layouts, enhancing operational productivity, reducing downtime, and improving workplace safety.

Thanks to the smooth, vibration-free motion of the Superbelt®, Magaldi conveyor systems prevent dust dispersion, significantly reducing workers’ exposure to respirable crystalline silica, and maintain noise levels below 75 dB(A), contributing to a quieter and cleaner environment for improved comfort and safety on the foundry floor.

With a track record of more than 1,800 installations worldwide, Magaldi supports its customers through a global network of subsidiaries in North America, Mexico, Germany, Australia, India, and the UAE, ensuring local presence, prompt technical support, and 24/7 spare parts availability anywhere in the world.

Driven by a passion for engineering excellence, sustainability, and innovation, Magaldi continues to deliver high-value solutions that strengthen foundry competitiveness, minimize environmental impact, and support the industry’s transition toward responsible, efficient, and long-term growth.