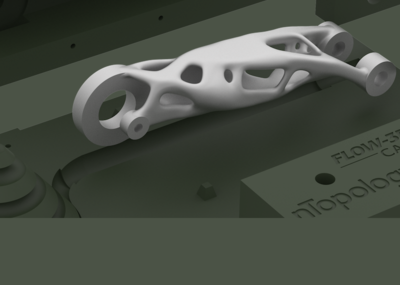

As one of the largest producers of critical cast-iron components in the United States, Grede is known for its commitment to light weighting and design solutions. Almost 90% of the castings made by the company involve a core. Most are very intricate, multiple-piece assemblies. Grede recognized that advanced manufacturing processes, like binder jet 3D printing, that enabled component weight reductions and faster response times to customers was the key to future growth. Read the story of how Grede became a 3D printing foundry.

“By nature, 3D printing contributes to precise, higher quality components,” said Cary Wood, CEO of Grede. “We saw the potential for additive manufacturing to support greater repetition of complex core constructions and invested in new equipment to make it a reality at Grede.”

"Instead of paying for four to five core boxes at $50,000 each, now we can print the design as one core.”

Tyler Hill

Plant Manager

Grede Iron Mountain

To read the Case Study please click here