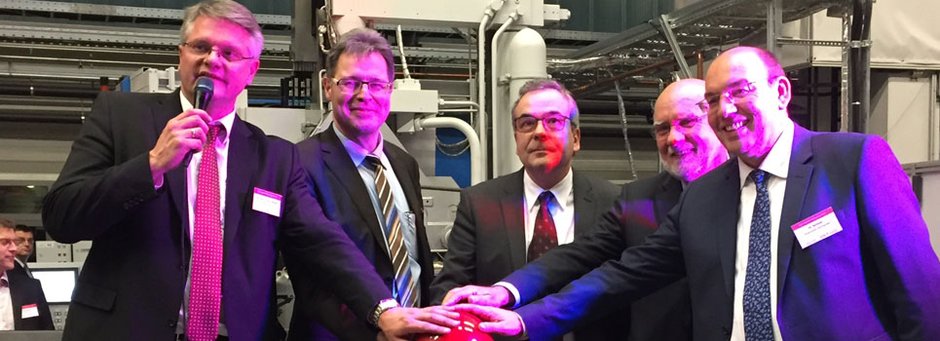

The specialized department of Foundry Technology’s facilities have been completed and the inauguration was celebrated on Thursday, December 8th, with an official ceremony. The Casting Technology department combines two large-sized casting cells and other equipment.

The University of Kassel is developing into an important location for basic research in the area of innovative casting technology, especially in the field of lightweight construction. The research infrastructure serves the transfer of knowledge to the casting industry, the medium-sized economy, as well as to the training of young academics.

New Equipment for the Metakus Hall

The equipment of the Casting Technology department includes, among other things, a Frech hot-chamber magnesium die-cast cell with a 580 ton clamping force and a 1,400-ton Buhler Carat aluminum / magnesium cold chamber die-cast cell with vacuum connection, FE materials, as well as various simulation and analysis laboratories. The facilities are housed in the Metakus Hall of the University in Baunatal. The university's metal-forming department also maintains a laboratory there, so that research in metal forming is now concentrated in Baunatal.

Under the direction of Prof. Dr.-Ing Martin Fehlbier, the field of foundry technology is being enriched through the research of innovative production and production processes in die casting, the development of materials with new materials for ultralight component components—also in the multi-material mix, up to their structural design and failure simulation. Several graduates of the field of foundry technology successfully applied for the EXIST Founder Grant from the BMWI (Federal Ministry of Economics and Energy). GTK cooperates with numerous German and international companies in the field of knowledge transfer.

Foundry Technology develops High-Tech Products

Foundry technology is gaining in importance in industries such as the automotive industry, but also in machine and plant engineering, the furniture industry, and in medical and energy technology. Many end or intermediate products, which are welded or assembled according to conventional methods, can be produced in one piece by means of innovative casting technology. This saves weight, time and resources. In the further development of electro-mobility technology, cast-iron construction plays a decisive role: on the one hand because the low weight of the components increases the range of the vehicles, and on the other hand because the drive block or the battery housings of e-vehicles are particularly suitable for production with casting technology.

The Casting Technology department has been in operation since last summer, with the equipment being completed recently. The equipment has a value of around €3.5 million for further industrial long-term loans in the amount of approximately €1.1 million. It was financed by the Deutsche Forschungsgemeinschaft (DFG), industrial interests and the University's own resources. The ceremony took place in form of a two-day, high-ranking casting colloquium on the subject of "Cast-iron Construction in the Context of New Mobility Concepts and E-mobility", which attracted around 200 people.

High-Ranking Casting Colloquium in Kassel – Dr. Flender invites Foundries for more Marketing Activities

It was an excellent mixture of participants from OEMs, machinery suppliers, scientists, consultants and the University members to discuss really relevant questions and future prospects of the metal-casting industry.

BDG Präsident Dr.-Ing. Erwin Flender calls the foundries for more marketing activities to feature their competence.

The challenges of alternative E-mobility, additive manufacturing, changing priorities and consciousness in parts of our societies have to be accepted as a real risk and an absolute opportunity for those who believe in castings.

Basically the casting industry should not be afraid of new exigencies, because they are performing very well and future orientated in Europe, but nevertheless they should be prepared for more and different competition between technologies and processes and point out their own advantages.

Regarding the demands and the needs of policy and economy this colloquium was taking part at the right time at the right place. The organizers should think about a new edition.

Abstract of the speakers list:

Current Situation and Propects for the Foundry Industry, Dr.-Ing. Erwin Flender

Volkswagen and alternative Drivelines, Dipl.-Ing. G.Hahn

Quo vadis Casting Industry regarding E-Mobility? Dipl.-Ing. J.M. Ségaud

Influence of E-Mobility on the global Aluminum Production, Dipl.-Ing. Rudolf Riedel

Aluminum Structureparts – Experiences from Daimler Mettingen, Dr.-Ing. L. Storsberg

The Mobility Revolution, Prof.Dr. A. Knie

and others

Contact:

Univ.-Prof. Dr.-Ing. Martin Fehlbier

Universität Kassel

Fachgebiet Gießereitechnik (GTK)

Tel.: 0561 804-7595

E-Mail: <link>sekretariat-gtk@uni-kassel.de

Internet: <link http: www.gtk.uni-kassel.de>www.gtk.uni-kassel.de

Sebastian Mense

Universität Kassel

Kommunikation, Presse- und Öffentlichkeitsarbeit

Tel.: 0561 804-1961

E-Mail: <link>presse@uni-kassel.de

<link http: www.uni-kassel.de>www.uni-kassel.de

Partner

Foundry Corporate News

Campus

Fairs and Congresses

Topic Pressure Die Casting

Topic Low-pressure diecasting

GER - Casting Technology Inauguration in Kassel`s University

Lesedauer: min

[5]