The Turkish foundry industry, known for its dynamism, holds a pivotal position within international supply networks. It has witnessed consistent double-digit growth annually, propelled by competitive pricing and investments in innovative technologies like sand 3D printers.

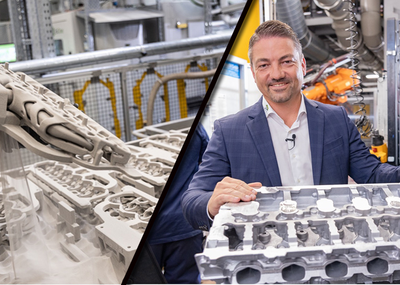

However, the industry faces a maze of challenges that heavily impact its operations and competitiveness. Some of the key challenges include increasing customers' demand for faster delivery, smaller batch sizes, and custom offerings. Cast parts are becoming geometrically more complex and their wall thicknesses are getting thinner, making them extremely difficult and uneconomical to produce conventionally. In addition to that, Turkish foundries operate in highly volatile markets and face stiff competition both domestically and internationally.

Want to learn how leading Turkish foundries like Döktas and Ekstrametal are mastering these tough challenges and beating the competition? Join our ON-DEMAND-WEBINAR on Foundry-Planet.com, where they will share their recipe for success in detail: Leveraging the fast binder jet sand 3D printing technology from ExOne to revolutionize the production of small series and prototypes for diverse applications, with a focus on design freedom and rapid casting.

Learn about the flexibility and ease of integrating the binder jet process into your foundry operations, the wide range of binder jet applications, and the significant advantages it brings over traditional methods. Lastly, find out the cost of ownership and the return on investment of this technology.

Secure your place on this insightful webinar and gain valuable insights from industry leaders.

Watch for free: How does sand 3D printing offer greater efficiency for Turkish manufacturers? (webinaris.co)