High performance moulding material for precision casting

Complex cast parts such as turbocharger housings play a central role in the de-sign of modern high-performance engines. Due to its particular characteristics silica sand has its limits as a moulding material when it comes to casting finely structured components, reduced wall thicknesses and perfect surfaces. Thanks to its high temperature load strength and a strong resistance to metal penetration, Kerphalite™ KF, a special sand, has proven itself suitable for these types of applications in many foundries.

In central Europe, silica sand is available in large quantities and in good qualities, and is widely used in foundries as an economical basic moulding material. But it also has neg-ative properties, which may lead to problems when producing sophisticated castings. These particularly include the socalled quartz inversion, i.e. the abrupt expansion of the specific volume at 573°C. It occurs during virtually every casting process and may lead to sand expansion defects, mainly in the form of finning (also called veining). The moulding material can crack under high temperature load, allowing liquid metal to seep into the resulting cracks and cavities.

Suitable alternative for silica sand

Foundries aim to avoid these casting defects and reduce the costly effort needed to rework the casting. This is all the more important when considering that casting geome-tries are becoming ever more complex and the demands for their dimensional accuracy and surface quality are becoming ever more exacting. If foundries want to avoid using more binding agents or adding gas-forming additives, they need a suitable alternative to silica sand as a moulding material.

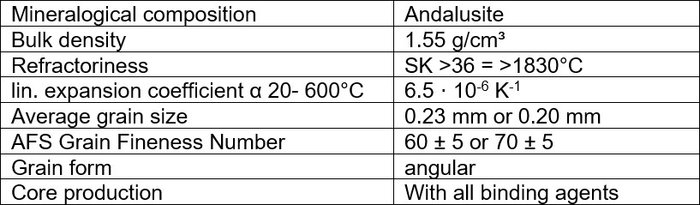

Kerphalite KF is a special sand with low thermal expansion, high refractoriness and a special grain geometry that enables very high core surface densities.

From stalky crystals to a special sand

Kerphalite KF is a natural material based on andalusite. Andalusite was first identified in 1798 and named after the Spanish province, Andalusia, though later this location turned out to be untypical for the mineral. In terms of its chemistry, andalusite is an aluminium silicate (Al2SiO5), which crystallizes in the orthorhombic crystal system and usually de-velops elongated, prismatic crystals with a square cross-section.

When a water distribution network was built in the north of Brittany, France in the 1960s, schist layers with aluminium silicate inclusions andalusite came to light.

Today, Imerys Refractory Minerals mines, treats and processes the andalusite in Brittany. The deposit is four kilometres south of Glomel and comprises several pits that are exploited in the form of terraces. Imerys Refractory Minerals mines about one million tons of stone per year. At the end of the multi-step and highly complex production pro-cess (breaking, grinding, separating, calcination and floatation), 80,000 tons of andalu-site are extracted. Several thousand tons of Kerphalite KF are used as a special mould-ing material for foundry applications across the world.

Processable with all binder systems and moulding processes

Kerphalite KF has a low density (similar to silica sand) and can be used in pure form or as blend with silica sand, as required. When blended, the share of Kerphalite KF should be between 30 and 100 percent. In this way, the user is able to adjust the sand blend to be both cost-effective and process efficient. The special moulding material is easily processable with all common binder systems. It is suitable for the Cold-Box as well as for the shell moulding process or the furan resin processes in iron as well as in steel castings. Kerphalite KF has also been used for 3D printing cores for over ten years.

Strong partnerships for success

The partnership with Hüttenes-Albertus has been decisive for the development of Ker-phalite™ as a special moulding material for precision casting in the European foundry industry. In the mid-1980s, Hüttenes-Albertus added Kerphalite to its product portfolio, and has been actively promoting the material’s advantages as a moulding material in the market ever since. HA's expertise in core production technology as well as its ex-tensive distribution network have contributed to establishing Kerphalite as a benchmark in the European foundry industry. Today, the special moulding material is used in a large number of foundries in Germany, France and many other European countries.

Dense core surfaces, low thermal expansion

There are two special properties that make Kerphalite KF a sought-after moulding material for difficult casting jobs. First of all, the low and linear thermal expansion plays, of course, an important role as following example shows:

A 400-mm-long canal core made of silica sand, if fully heated to a casting temperature of 1380°C, would expand by a total of 9.3 mm. This means the core either develops thermal fatigue cracking resulting in finning on the casting, or it buckles or breaks. However, when using Kerphalite KF as a moulding material, the core would only ex-pand by 3.8 mm under the same conditions.

Secondly, the broken grains of the orthorhombic crystal with their angular cross section create a highly dense moulding surface. This effectively helps to prevent the penetra-tion of liquid metal, especially in comparison to cores that are produced from spherical sand grains of the same average grain size.

Properties of Kerphalite™ KF

<link http: www.foundry-planet.com fileadmin redakteur material news_material _top external-link-new-window external link in new>

Proven applications in foundries

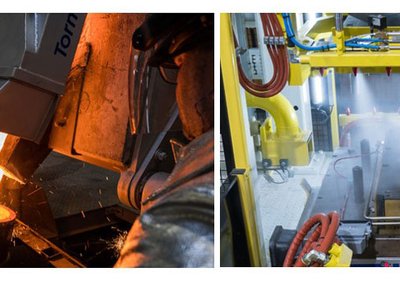

Typical applications for Kerphalite KF are cores for hydraulic valve housings, canal and water jacket cores for cylinders and cylinder heads, also subsections of the water jacket core (as key core), as well as cores for the helical turbine housing of the turbochargers. In all of these cases it is important to create fine, thin-walled and dimensionally accurate casting parts with flawless surfaces.

Foundries, such as Harz Guss Zorge GmbH and many others, rely on this special sand for casting turbine housings and cylinder heads. The casting has a complex geometry and has to withstand high thermal loads to fulfil its important function in the end product, the turbocharger. The turbine housing has to meet the highest quality standards in order to achieve effective flow behaviour. It is imperative to have a reliable procedure to avoid finning, because subsequent cleaning requires a lot of effort or rework is impossible.

When using Kerphalite KF as a moulding material, foundries are on the safe side. They achieve a core with the lowest thermal expansion and the highest surface quality, able to withstand high casting temperatures even in the most critical areas: a core that meets all requirements for producing a perfect cast part for a high-quality, high-performance product.