Vulcan Engineering incorporates the latest in advanced safety features while still offering reliable efficient equipment.

The Fox® Air Float Cut-Off machine is ideal for gate and riser removal on small to medium size castings, or castings on runner bars or trees. It is well suited for processing castings that are too heavy for operators to handle, as the air float feature makes moving large weights almost effortless. Compressed air is used to “lift” the gondola to allow the operator to “float” it around the table, and use the laser guide to align the casting into the proper cutting position. Once inposition, a vacuum is used to securely hold it in place during cutting. The saw uses hydraulic down pressure for fast efficient removal of risers and gating.

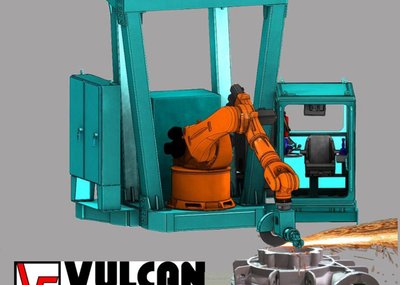

The saw shown is designed to be installed in its own room; other models are available with full enclosures for installation around other workers. Fox® grinding and cutting equipment has proven reliability, and is designed to work effectively in rugged, dirty foundry environments. Precise cutting and efficient processing is only part of the design, to truly enhance th is system Vulcan has added several advanced safety features

All of the above features, as well as incorporating redundant safety shutoff valves with monitoring, make this one of the safest cut-offs on the market. For more information on cutting and finishing equipment, meet with our team of experts at GIFA 2015 at booth 16D11 or please visit our website at: <link http: www.vulcangroup.com. _blank external-link-new-window external link in new>www.vulcangroup.com.

Partner

Topic Automation

Topic Discharging, Decoring, Fettling, Finishing

Foundry Corporate News

GIFA 2019

Increased Safety Measures in Cut-Off Technology

Lesedauer: min

[8]