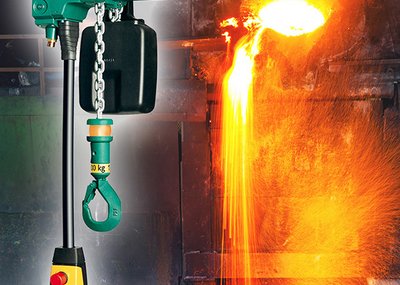

The specialised high-performance handling products manufactured by the J D Neuhaus company are engineered for extremes, and are suitable for operation within chemical, oil and gas and general industries involving hazardous working areas including those subject to potential explosion risks. Their hoist and overhead crane mechanisms are strong, fast and silent, providing high levels of safety with ease of operation. They combine lube-free, low maintenance operation with 100% duty ratings and unlimited duty cycles. The products are insensitive to dust, humidity and temperatures ranging from -20°C to +70°C.

It is essential that the correct installation, operating and regular inspection servicing procedures are undertaken and maintained for these products to ensure long-term, trouble-free operation of all mechanical and power-operated components.

To ensure that users obtain the best value for money from their investment in handling products, the JDN company can provide offsite/onsite services including supervision, installation, training, inspection, maintenance and repair, together with the supply of spares, service kits and full refurbishment facilities. All work is undertaken under full JDN personnel supervision and is carried out in co-operation with external certification authorities where required.

Appropriate products and services available from the JDN service department include:

• Prior inspection for the planning of the building site

• Organisation of the building site and coordination with all participants

• Provision of assemblyman

• Commissioning

• Approval of the hoists/cranes on client terms

• Approval in cooperation with external certification authority (3rd party)

This is then followed-up where required with regular maintenance and annual inspections by JDN trained engineers/technicians covering:

• Annual maintenance under compliance with the legal requirements and the JDN maintenance plan

• Introduction into the JDN maintenance database to ensure clients are reminded of upcoming planned maintenance

• Maintenance contracts that provide precise cost control details

This is also then supported with full maintenance/repair/modification facilities including:

• Repair and modification in JDN' s own workshops

• Repair and modification at client facilities

• Conversion in co-operation with JDN R&D requirements

• Overload tests

A full spare parts provision incorporates support for the choice of spare parts, compilation of spare parts and service kits for retention in client warehouse and the shipping of the spare parts worldwide.

In addition, specific customer personnel training, all tailored to meet client needs is available either on-site, at customer facilities or one of the widely located JDN sales companies. J D Neuhaus are represented in more than 90 countries (including Germany, France, Great Britain, Singapore and USA), together with 70 other branches throughout the world.

After expiration of the theoretical operating life (at the latest after 10 years) all hoists are currently required to undergo a general overhaul. For J D Neuhaus hoists, this work can be undertaken within their service centre or by one of the JDN authorised service partners.

If there is a short term demand for hoists of any capacity then a full rental service, including delivery, is available and hoists can be customised to meet specific client requirements.

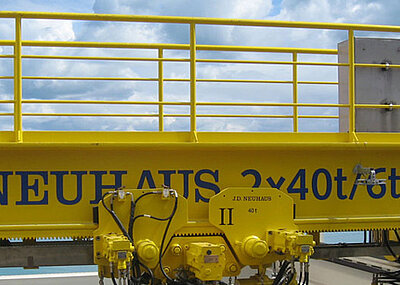

The J D Neuhaus air operated handling equipment, including hoists and cranes for operations within light, medium and heavy duty engineering, cover individual lift capacities from 250kg up to 100 metric tonnes. Even heavier lift requirements can also be achieved using multiple hoists and integrated synchronised lift and traverse controls for units operating in tandem or parallel configurations. Land based or offshore oil/gas platform mounting can be accommodated, including installations on sea-going vessels where ocean swell movements can be minimised by the use of rack & pinion drives incorporated into horizontal overhead beams and the mechanised trolley drives. Specialised hoists for underwater handling operations, or extreme low cryogenic conditions down to -45°C are also available, together with optional hydraulic drive mechanisms where compressed air power supplies are not readily available.

Partner

Foundry Corporate News

Topic Plant Technology, Equipment

J D NEUHAUS AT YOUR SERVICE

Lesedauer: min

[1]