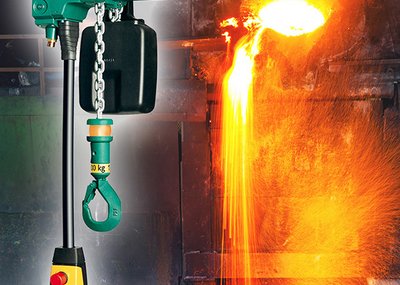

Crane systems manufactured by the J D Neuhaus company can be supplied with Atex classifications EX II 2 GD IIA T4 / EX II 3 GD IIB T4, with increased spark protection also available for explosion level II C. Their products are currently used worldwide, operating in some of the most dangerous dust laden conditions as well as hazardous, toxic and potentially explosive atmospheres. Typical applications include mining, tunnelling, foundries and cement plants, with toxic and hazardous locations including chemical processing, while oil and gas production on land or offshore involves some unique heavy load handling requirements in addition.

All load lift, lower and traverse operations operate off a pneumatic air-line pressure of 85psi (6 bar), with optional hydraulic operating systems also available. This eliminates the potential hazards and dangers associated with electrically powered equipment when operating within areas of high dust or humidity.

The JDN range covers both single and double girder overhead travelling cranes, together with slewing jib cranes and underslung cranes incorporating purpose designed low headroom hoist trolley designs. Cranes with individual hoists having load capacities up to 100 tonnes can be supplied, as well as multiple hoist crane products operating with single or twin parallel beams, while also providing individual or synchronised hoist control systems.

For offshore lifting operations, including on sea going vessels, cranes can be supplied with rack and pinion drive systems for safe operation even in bad weather conditions. Super-silent operation is combined with sensitive controls including an automatic safety function for load-lowering in the event of power supply failure.

Special purpose, fully customised cranes can also be supplied to customer specifications. For companies looking for self-build projects, JDN also supplies crane kits. These are designed for the manufacture of overhead travelling cranes and underslung cranes. They feature the use of a single span beam providing the hoist support and running platform. This includes both overhead travelling and underslung mountings which are supplied with crane drive motors and space saving energy chain systems for the power supplies for both long and cross travel movements.

Typical customised products that have been supplied include a hydraulic semi-portal crane, with a lift capacity of 80 tonnes for use on a drilling rig. This incorporated twin monorail hoists, together with four JDN hydraulic drives for the crane travel movements.

Other specialist products for the oil and gas industry include an 80 tonne double girder overhead travelling design for ‘xmas tree’ handling on a semi-submersible rig. Another purpose-designed product provided a 200 tonne lift capacity for handling BOP equipment offshore. Cranes for use in the corrosive atmospheres of the galvanic industry have also been supplied.

The J D Neuhaus cranes are insensitive to dust, humidity and aggressive atmospheres as standard, operating within a temperature range of -20°C to +70°C. They provide 100% duty ratings with no downtime and only minimum maintenance requirements. Overload protection and fail-safe braking are incorporated, together with emergency-stop safety features. Special limit switch arrangements for end-travel, anti-collision and protected zone status are also incorporated as required.

Partner

Foundry Corporate News

J.D.Neuhaus - EXPLOSION PROTECTED CRANE SYSTEMS

Lesedauer: min

[0]