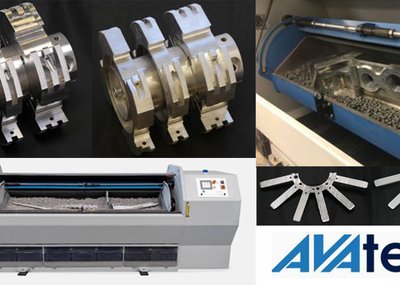

With the acronym LCD (in Italian TSL) we refer to another R&D Industry 4.0 project carried out by Meccanica Pi.Erre. It is an innovative process solution concerning the Laser Cutting & Deburring (here comes the acronym LCD) of light alloy foundry castings inside a robotized cutting cell.

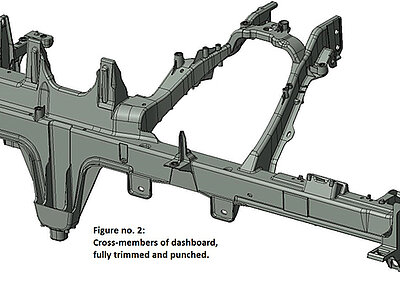

It started in 2017 when Mr. Ruggero Pederzoli, supported by our internal engineering team, was developing a valid alternative to the mechanical trimming and deburring operation of aluminum and magnesium castings. This led to the official presentation in Autumn 2020 to different important players in the automotive industry, particularly to TIER1, structural components manufacturers.

Cutting in three dimensions and seven axes

We talk about a cell composed of an agile and sturdy robot equipped with a mechanical arm with a laser cutting head. This head has a fiber laser source with a power of 5 kW. Important to stress out the fact that we are referring to a cutting process and no longer to trimming. Cutting takes place completely in three dimensions with seven axes. This is the first system in the world with such features and for this reason, this project was also covered by a European and an International patent.

The vision of Meccanica PI.Erre is that this solution can in future be used alongside the mechanical trimming-deburring, if not, in some cases, this might replace the traditional trimming process entirely. The robotized cell has been working at Meccanica PI.Erre since January 2020 and the company has been currently offering a cutting service during sampling and pre-series phases. Where customer has small batches and has big advantage to rely on such service rather than investing in complete trimming equipment.

Further details on this important and revolutionary technical solution will be available in next issues, we keep you informed.