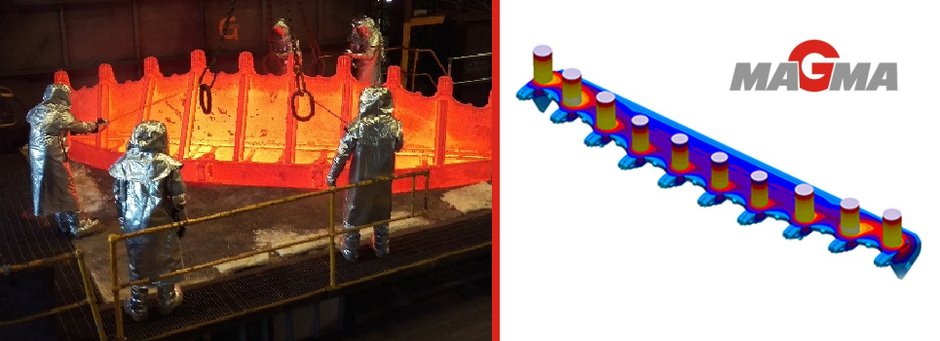

In 2016, CR designed the DecaEdge™ cast lip, which was designed to fit large mining wheel loaders. CR is the only manufacturer in the world to offer a range of cast lips for large mining wheel loaders. The first iterations of the DecaEdge™ design required fabrication from three separately cast parts, each two meters in length. The entire process for manufacturing tied up space, as well as labour,

in the workshop. The production team identified that the foundry had the physical capability to produce the part as one piece, instead of three.

The main challenge of the redesigned part was to stay within the bounds of dimensional tolerances of the finished product. The increase in size and complexity of the geometry made this a difficult task. The DecaEdge™ cast part is 6.2 m long and 1.2 m wide with a weight of 5000 kg.

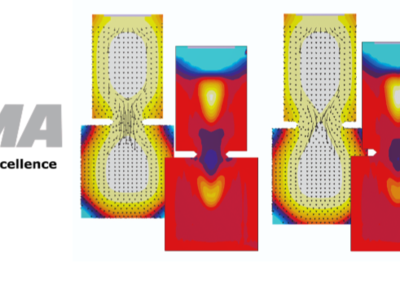

The team spent hours with MAGMASOFT ®

to design and analyze the runner system to have a balanced filling, as well as a proper temperature distribution at the end of the filling. After evaluation of all technical aspects, the team concludedthat the finished tolerances could be achieved, and a case was proposed to management, including cost and quality benefits.

There were two different benefactors from this project. The first benefactor is CR’s customers: the redesigned part with optimized plane alignment, spade angle and material placement, as well as removal of the outdated plate lip feature, lead to the extended lifetime of the DecaEdge™ product.

CR’s benefit was a significant reduction in production costs. MAGMASOFT ® helped to secure the performance of the cast part despite the complex design, and the part was successfully cast at the first pour. This exercise made the manufacturing process more efficient, reduced heat treatment cycles, eliminated welding fabrication and reduced the number of molds required. Besides the cost reduction, the Maryborough foundry also enjoyed the benefit of higher productivity; It is able to now manufacture more cast lips per month.

Courtesy of CR Foundry in Maryborough, Queensland, Australia