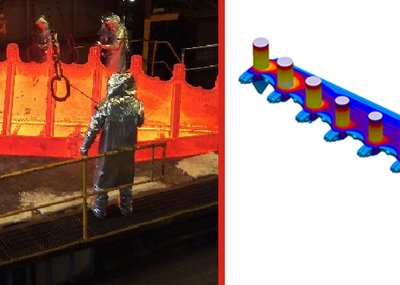

After 40 years of its introduction, simulation in casting process has become an essential tool for various aspects in design and process optimization. Today, the results obtained from simulation allow prediction of many different quality aspects and address the entire manufacturing route. This supports the foundry expert to gain quantitative information regarding the best possible conditions for the required casting quality, while maximizing casting yield and reducing manufacturing costs.

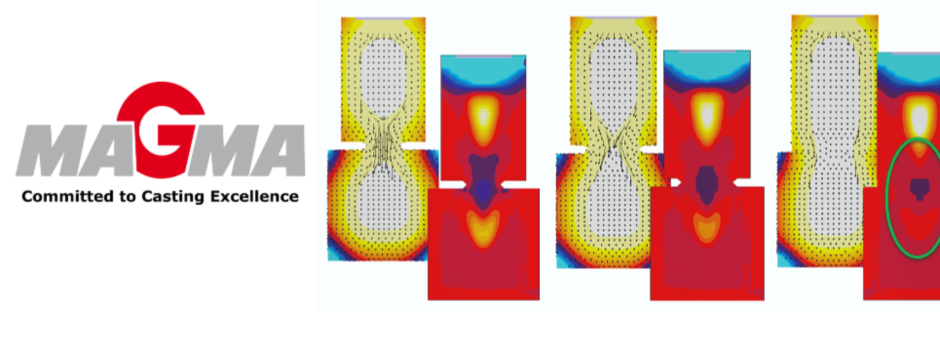

MAGMASOFT® has recently published this paper…

which illustrates the benefits of Autonomous Engineering for steel castings by using different industrial applications as examples. In addition, new capabilities and current R&D activities were also discussed. By applying these developments, the steel foundry will be offered unique opportunities to achieve new and optimized applications as well as to define reliable manufacturing routes before the production of a steel casting.

The diversity of steel grades, the variety of factors that affect casting quality and complex interactions between physics, metallurgy, casting geometry and the process sequence all play a role in the quality of a steel casting. Empirical knowledge, even if supported by insights of simulation, just confirms a single predefined operating point but does not provide information about the possible optimum nor about the robustness of the chosen process window.

In MAGMASOFT®, Autonomous Engineering overcomes these limitations by offering the foundry expert a virtual field for systematic experimentation. Autonomous Engineering is a methodology utilizing multiple MAGMASOFT® simulations as a set of virtual experiments in order to achieve the best possible solution.

Due to the diversity of steel grades and the flexibility of the processing route, this new approach can only provide quantitative information for a better and faster decision-making process. This will strengthen the steel casting as a robust and competitive manufacturing process for especially for high integrity components used for advanced applications in industry worldwide.

Click here to get access to the full publication for free!

Follow MAGMA Engineering on LinkedIn for more news and updates about autonomous engineering and more.