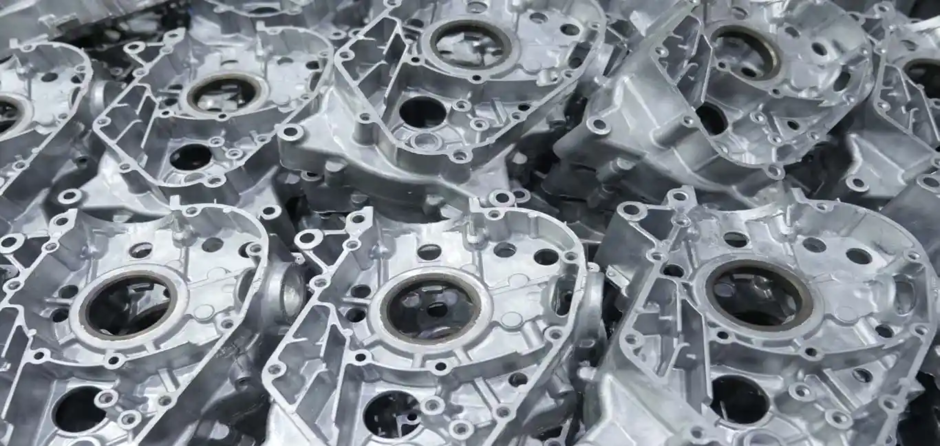

PipeHawk PLC on Wednesday said it has been awarded a contract by JVM Castings Ltd to design, manufacture and supply a suite of automated systems for the insertion and assembly of self-piercing and clinch nuts into a range of automotive aluminium castings.

PipeHawk, the Hampshire, England-based provider of technology for highways and for the automotive, rail and aerospace industries, said the contract awarded to its subsidiary QM Systems Ltd will generate around GBP800,000 of revenue for QM and is due to be delivered within PipeHawk's financial year ending June 30.

The contract will make use of QM's latest automation process, PipeHawk said, which combines assembly with component mistake proofing to ensure assembled castings are manufactured correctly.

PipeHawk said the buyer JVM is based in Worcester, England and is the UK's largest aluminium diecasting specialists.

"QM have formed a close partnership with JVM over the last 10 years and are JVM's go to partner for the supply of the majority of their assembly equipment. Over the years, QM has provided JVM with a range of systems to assemble SPAC Nuts, SPAC Studs, Rivnuts, Rivstuds as well as other components into a diverse range of castings utilised within the manufacture of automobiles with final supply into a number of original equipment manufacturer vehicle manufacturers," said PipeHawk Chair Gordon Watt.

"It has been a pleasure to work closely with JVM over these last 10 years and it is a testament to the service and support that QM offers its clients that JVM continues to work closely with QM for its casting assembly needs year on year."

Shares in PipeHawk were untraded at 11 pence each in London on Wednesday late morning.

Source: www.morningstar.co.uk