Background

For an induction melting furnace to operate safely, a powerful water cooling system must be in place to prevent overheating of the induction coil, the frequency converter and the capacitors. In this context, particular importance is attached to a low energy consumption of the cooling water pumps and fans of the air cooler or evaporative cooler as well as to the capability of recovering a large amount of heat from the cooling water.

Thanks to numerous developments, induction furnace technology has reached a high overall level of efficiency. In cast iron melting, the efficiency rate may amount to as much as 75 % (Fig.1 ).

Power dissipation occurs mainly in the form of ohmic losses from the coil and electrical system, whereas thermal losses are low. In cast iron melting these ohmic losses amount to approx. 20 – 25 % of the power input, while for copper the figure goes up to as much as 35 – 40 %. Thus, in a cast iron melting furnace with an 8 MW power rating, the amount of power dissipated as heat will be in the order of approx. 2 MW. This high amount of waste heat must be reliably transferred away via a powerful water recooling system to maintain an appropriately low water temperature in the supply line. Needless to say, intense research efforts are being made to reduce ohmic losses further. Thus, reductions by 4% and 9% have been achieved, depending on the metal being melted, through the use of a special coil design. A second option is to recover, and hence re-use, the large quantity of heat carried in the system's cooling water. It should be noted here that heat recovery works best at an elevated cooling water temperature which should, moreover, remain as constant as possible. At the same time, the energy consumption of the cooling water pumps and of the fans serving the air cooler or evaporative cooler should be reduced.

The basic parameters in rating a water recooling system are the water demand of the components to be cooled, the maximum supply and return temperatures, and the acceptable temperature rise. In some cases, two mutually independent closed cooling circuits are employed in view of the different water quality requirements for cooling the furnace and for cooling the electrical equipment (converter, capacitors). Often the furnace and the electrical system are served by one common cooling circuit, especially where IGBT converters are used. The water recooling system is dimensioned and its operating regime is designed for the full rated power of the melting furnace plus a defined safety margin. The acceptable temperature limits, which amount to 85 °C for the furnace coil and 45 °C for the electric circuit, must not be exceeded.

As the cooling water pumps run at full speed regardless of the amount of heat actually dissipated, the system continues to deliver its full cooling output even in operating modes such as, e.g., holding the melt at temperature or shutting down the furnace. As a result, the return water temperature in the coil circuit will drop while the electric power demand remains unnecessarily high. The drawbacks of this former practice can be summarized thus:

- varying return water temperatures

- temporarily low temperature level

- unnecessary power consumption of the pumps in the water recooling system

The new approach

Together, OTTO JUNKER und INDUGA have developed the intelligent water recooling system referred to as SmartReCooler (SRC) which adapts its cooling output to the actual heat losses of the induction furnace installation.

The system's cooling output is proportional to the temperature rise and flow rate of the cooling water. It supplies just the right cooling water throughput for the current cooling requirement, thereby maintaining return water temperatures constant and keeping the water recooling system energy-efficient. Pump speeds are determined by a smart controller. As the control unit also takes into account the furnace's electric power input, the cooling system responds very quickly to new furnace operating conditions.

In circumstances requiring only little heat to be removed, e.g., when the furnace is shut down and allowed to cool over several hours, the system runs in energy-saving mode. In this mode it keeps up a minimum water supply that suffices for all cooling circuits. The SRC system can respond autonomously to new heat loss situations at any time. In energy saving mode the cooling water pumps draw very low power, i.e., very little electricity is consumed. The energy saving potential depends very much on the furnace operating regime, i.e., on how long the furnaces are run in holding or cool-down mode or with reduced power input.

At KSB AG, the leading manufacturer of pumps and pump systems, this new technology was used on one of two identically designed Monomelt furnaces with independent water recooling circuits which had been ordered for the company's Pegnitz site. As one furnace plant featured the smart SRC system while the other was equipped with traditional water recooling, the benefits of the new system could be objectively evaluated.

The furnaces are designed to melt both cast-iron and steel. Each of the two plants consists of a 2-tonne coreless induction furnace with an IGBT converter rated for 1,500 kW. The nominal frequency can be set at 500 or 125 Hz. The installations are equipped with a JOKS melt processor, a weigh scale, extractor hoods and a hydraulic power pack.

The water recooling system of each melting furnace has separate cooling circuits for the furnace and the electrical equipment and uses a glycol-free water-to-air cooler. The pump rack in the furnace circuit carries two 7.5 kW pumps operating in a redundant mode. The cooling circuit for the electrical equipment uses only one pump of the same rating. The water recooling system is controlled by the furnace PLC via a remote substation.

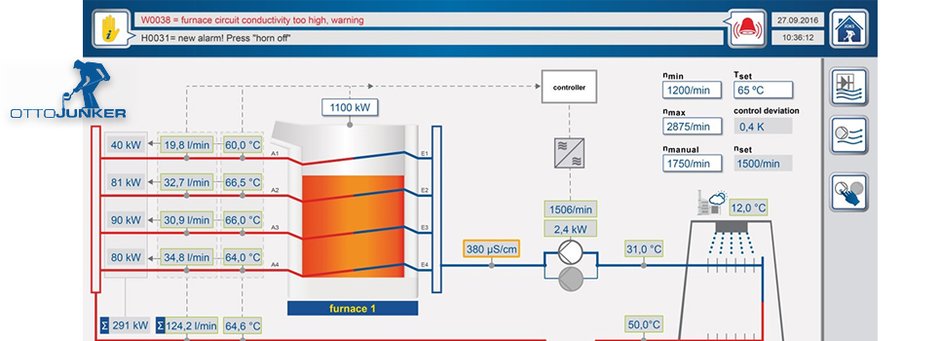

The extra hardware to be fitted for the SRC system consisted only of the variable frequency drive units for the two furnace-circuit pumps, a few temperature sensors, and some small accessories. This was in addition, needless to say, to the new smart software developed for the application. This software ensures that the cooling water flow rate is adapted at once when the cooling water demand changes suddenly, e.g., because the furnace is set to full power by the operator or the load shedding system. A simple control scheme based on water temperatures alone had been found inadequate. Fig. 2 shows a typical screen menu, albeit for a solution based on a water-to-water cooler.

A water-to-water cooler fed from the municipal water supply is fitted in the electrical equipment cooling circuit for the event that the air temperature exceeds 30 °C and the water-to-air cooler can no longer adequately cool the more heat-sensitive converter assembly. For heat recovery, a plate-type heat exchanger is integrated into the circuit.

By now the two Monomelt systems have been in operation for five months, and a first comparison between the traditional and new water recooling systems can be made.

Considering the different service conditions of the two furnace systems it can be said that the variable-frequency drive units of the cooling water pumps save a lot of energy. Thanks to the use of the SRC the energy consumption of the water recooling system could be reduced by more than 30 %.

Mr. Wagner of KSB AG's Pegnitz-based foundry production engineering unit had this comment: "The scheme using VFD-controlled pumps in the cooling circuit has proved a full success at our site. In the five months since the melting system was commissioned, we have benefited from a trouble-free operation and substantial energy savings. In our production conditions, we save so much power that the extra cost of frequency-controlling the cooling pumps will be recovered within just about one year. KSB AG now plans to retrofit the second coreless induction furnace, which does not yet feature frequency control of the cooling water pumps, to this new technology."

Moreover, the new system has led to higher and more constant water temperatures, which augurs well for the intended installation of a waste heat recovery system.

Conclusion

The smart SRC system has successfully proven itself in practice and the specified targets were achieved. The use of this control scheme clearly increases the energy efficiency of a water recooling system, apart from delivering a constant temperature that facilitates energy recovery. Further benefits include a rapid adjustment to the melting furnace's operating regime plus an extended service life of cooling system components. In all, the economic benefits yield a short payback period. These advantages are confirmed by the fact that KSB AG now aims to convert its second melting furnace to this technology as well.

It remains to be noted that a conversion of existing water recooling circuits to the new system can take place at short notice and with little installation effort. Work is now ongoing to realize this system for DUOMELT applications as well (two furnaces, one frequency converter) and a solution for controlling the fans of the air cooler or evaporative cooler is in preparation. The system is also suitable for use on other water-cooled thermoprocessing equipment.

M. Eng. Michael Dahmen

Otto Junker GmbH