Three years after the commissioning of a preservation line at ND Coatings, a strategic partner of the Meyer Werft shipyard in the German town of Papenburg, Rösler has now delivered a second line for the Meyer Werft shipyard in Turku, Finland. This is the largest equipment project ever undertaken by Rösler.

The acquisition of the shipyard in Turku in 2014 was a strategically important milestone for the Meyer family. It coincided with substantial investments in state-of-the-art equipment for the production of cruise ships. These included a preservation line with leveling stations for bulb flat steel, straight flat steel profiles and steel plates, all designed and built by Rösler. A key factor in the customer’s decision to go with the Rösler concept was the high productivity and reliability of the preservation line Rösler had supplied to ND Coatings, the strategic partner of the Meyer Werft shipyard in Papenburg for corrosion protection, insulation and surface treatment. This is one of the most modern and eco-friendly preservation lines in the world!

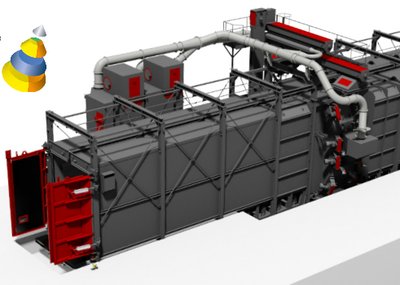

Fully automatic line including two shot blast machines

The 225 meter (740 feet) long shot blast and leveling preservation line was completely custom engineered to the needs of Meyer Turku and consists of an inter-linked work piece transport system, pre-heaters, two independent shot blast machines, suitable leveling systems for beams and plates and a paint station with dryer. All system components are linked with each other and integrated into the production control system of the shipyard. Upon arrival of the work pieces at the line entrance, the control system automatically determines if the work pieces must be cleaned, shot blasted, leveled, with which color they must be painted, or if they must only undergo a partial process. For every finished component all process parameter are reported back to the production control system allowing for complete and precise documentation.

The steel profiles, which are stored outdoors, are covered with rust or scale from the roll forming process. Depending on the season, they may also be covered with snow and ice. Seven work pieces are combined into a single batch on the transport system and are passed through the cleaning station/pre-heater for de-icing – if required - at a speed of 3 m (10 feet) per minute. In a subsequent stage the work pieces undergo a blast cleaning process in a roller conveyor shot blasting machine, type RRB 16/5. Four Gamma 400 G turbines with a drive power of 15 kW each ensure optimum blasting results. They are mounted on the roof and bottom of the blast chamber made from manganese steel. Easy to replace, overlapping manganese steel liners provide additional protection against premature wear. After travelling through a blast media brush- and blow-off station the profiles are aligned in single file for passing through the subsequent leveling system at a speed of 30 m (100 feet) per minute. Faulty profiles are immediately discharged from the system. The profiles within specs are combined into batches in the subsequent batching station with batch widths of up to 3,200 mm (126”).

The steel plates, stored in a roof-covered outdoor area, can be up to 100 mm (4”) thick, 3,300 mm (130”) wide and 24,000 mm (945”) long. They are picked up by a magnetic portal crane and placed in a centered position on the load station of the roller conveyor, the so-called main transport line. A sensor monitors the entire loading process. In the first stage the steel plates are passed through a blow-off station for the removal of water and other debris followed by a pre-heating step. From there they enter the RRB 35/6-HD roller conveyor shot blast machine at an average speed of 5 m (16 feet) per minute. The blast machine is equipped with eight (8) high performance turbines, type Rutten Gamma 400, with an installed drive power of 37 kW each. To minimize the wear rate and facilitate maintenance, the blast chamber, fabricated from manganese steel, is lined with overlapping, easy to replace manganese steel plates. After the removal of residual blast media in a brush- and blow-off station the work pieces undergo a leveling process.

To allow for the channeling of shot blasted batches of profiles onto the main transport line for painting, the loading of raw steel plates stops automatically, as soon as a finished batch of profiles is standing by. These batches are passed through the various stations, even permitting the profiles to be pre-heated and undergoing a secondary blast process.

Coating with a minimum of overspray and solvent recovery

The paint process at the end of the line takes place with solvent-based 2-component paint types in two colors, which are automatically and instantly mixed as required. The paint is applied with spray guns from above and below the work pieces. To minimize overspray, the spray guns are controlled by a work piece recognition and displacement measuring system. The solvent used for rinsing and cleaning is conditioned and recovered in a processing plant allowing the recovery and recycling of 98% of the material.

The drier was designed to ensure fast and optimum curing of the paint. It is equipped with gas burners and recirculation nozzles at the top and bottom of the cabin.

In a last step the plates and profiles are staged at various unload stations for downstream manufacturing operations as prescribed by the production control system.